Method for curing substances by UV radiation, device for carrying out said method and ink cured by UV radiation

A technology of curing substances and ultraviolet rays, which is applied in the direction of ink, printing post-processing, general parts of printing machinery, etc., and can solve problems such as increased curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

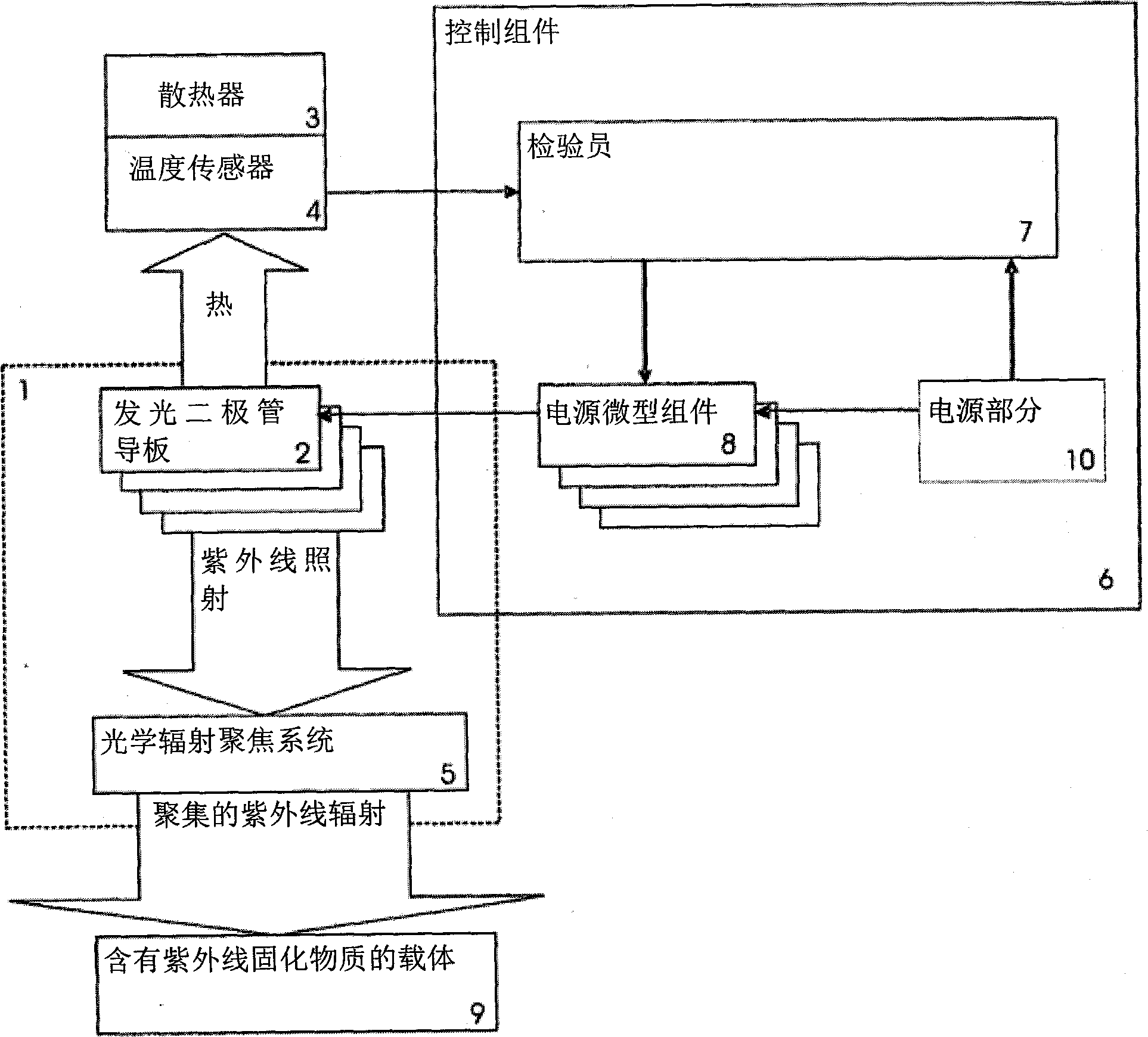

AI Technical Summary

Problems solved by technology

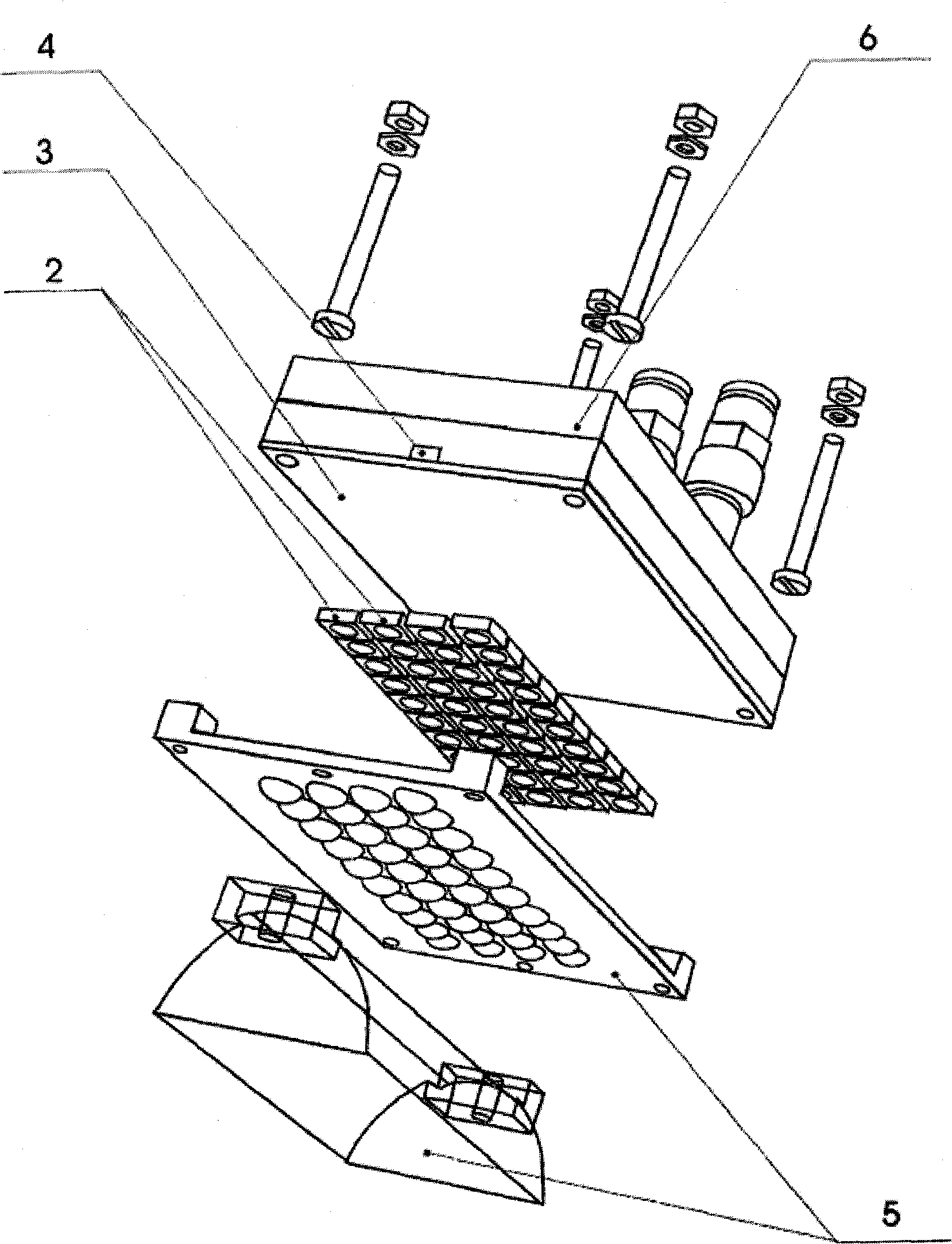

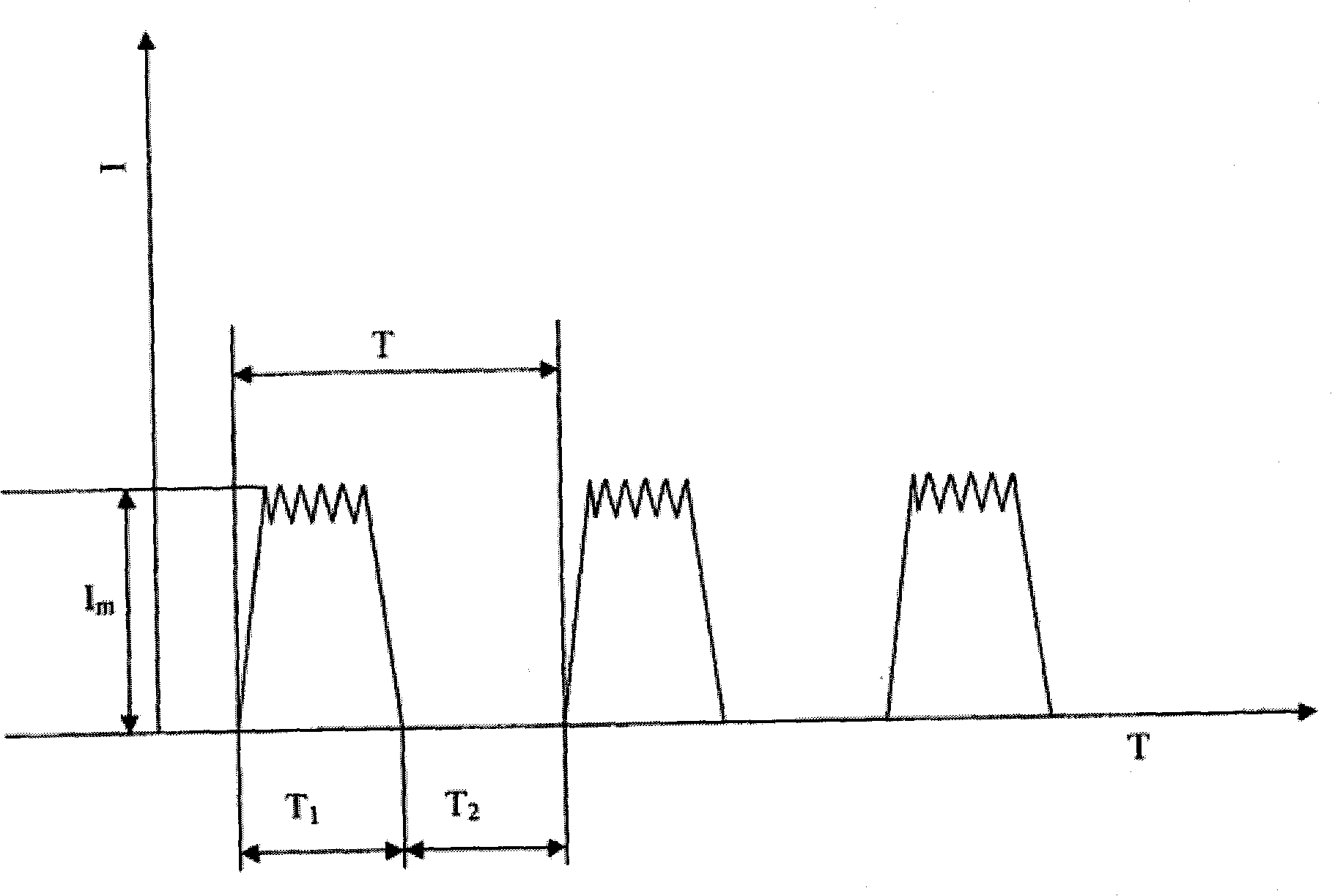

Method used

Image

Examples

Embodiment 1

[0106] Complete the preparation of the UV curing white ink.

[0107] To do this, fully load a fine mill in a laboratory chamber with a capacity of one liter:

[0108] One kilogram of ceramic granules with a diameter of 0.6-0.8 mm; two hundred grams - white paint, oxides of titanium in the anatase form (produced Kronos 1071); 550 grams - metamorphic treated acrylate with a dual function (produced ViaJet 400 CYTEC); 25 grams of superdispersants CH13 and CH10S (produced by TATI); 0.075 grams of light stabilizer NPLA (produced by WAKO Q1301) were pre-dissolved in 1.425 grams of diacrylate-dicarboxypropyl ether.

[0109] Grinding and degumming (gelling) are then carried out during 50 hours before obtaining particles of the same weight with an average unit size of less than 0.5 microns. At the end of this operation, one hundred grams of monofunctional acrylate (isobornyl acrylate produced by CYTEC) was added.

[0110] The components of the material obtained are then filtered throu...

Embodiment 2

[0115] Complete the preparation of the UV curing black ink.

[0116] To do this, fully load a fine mill in a laboratory chamber with a capacity of one liter:

[0117]One kilogram of ceramic particles with a diameter of 0.6-0.8 mm; 75 grams - Carbon black paint Black 7 (gas carbon black SB250 produced by Degussa); 350 grams - metamorphic treated acrylate with dual function (ViaJet 100 produced by CYTEC); The amount of dispersants CH13 and CH10S (produced TATI) is 75 grams each; 0.225 grams of light stabilizer NPLA (produced WAKO Q1301) is pre-dissolved in 4.275 grams of diacrylate-dicarboxypropyl ether.

[0118] Grinding and degumming (gelling) were then carried out during a period of 15 hours before obtaining the same weight of particles with an average unit size of less than 0.5 microns.

[0119] Then to the obtained coating layer, add: 1520 grams-dual-functional modified acrylate (ViaJet 400 produced by CYTEC); 300 grams of monofunctional acrylate (isobornyl acrylate produc...

Embodiment 3

[0125] Complete the preparation of the UV curing blue ink.

[0126] To do this, fully load a fine mill in a laboratory chamber with a capacity of one liter:

[0127] One kilogram of ceramic particles with a diameter of 0.6-0.8 mm; 30 grams - blue paint Phthalocyanine blue 15:3 (manufactured by Hostapern BlueB2G-D Clariant); 350 grams of metamorphic treated acrylate with dual function (manufactured by ViaJet 100 CYTEC); super dispersant CH13, CH13B, CH11B, and CH-10S are each 3 grams (produced by TATI); 0.225 grams of light stabilizer NPLA (produced by WAKO Q1301) are pre-dissolved into 4.275 grams of diacrylate- Dicarboxypropyl ether.

[0128] Milling and degumming (gelling) were then carried out during a period of 15 hours before obtaining the same weight of particles with an average unit size of less than 0.5 microns.

[0129] Add then to the coating layer that obtains: 1853 grams-the acrylic ester (produced by ViaJet 400CYTEC) of modification treatment with double functio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| tackiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com