Ferro-magnetic quenching metal strip coiling device

A coiling device and cold metal technology, applied in the field of quenched metal strip manufacturing, can solve problems such as strip tearing, insufficient effective bonding area, and distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

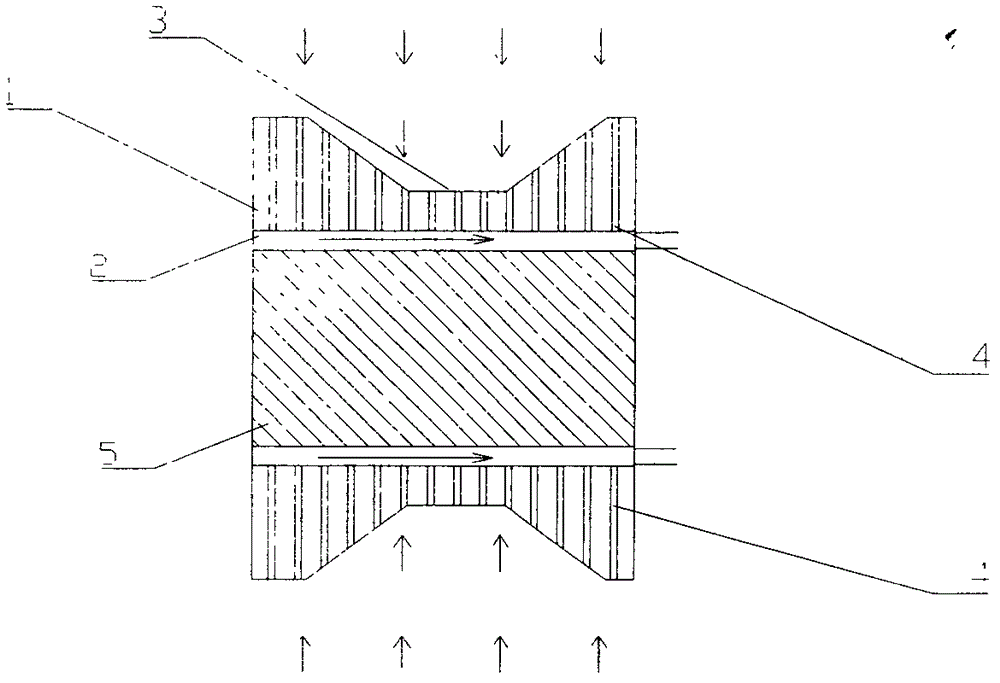

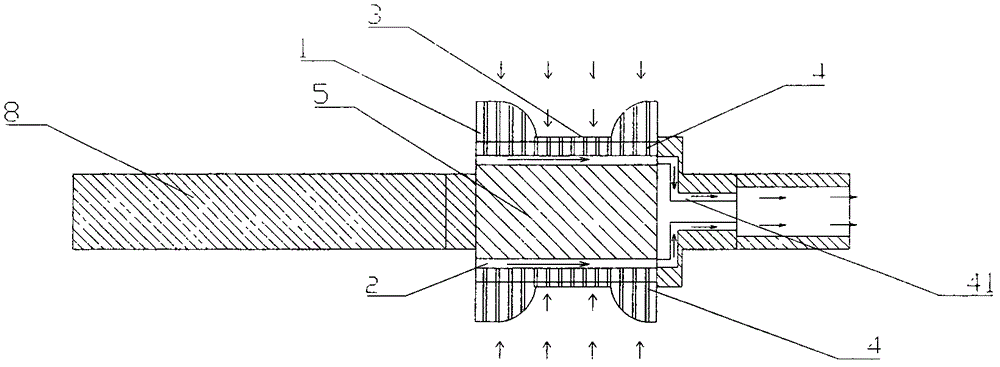

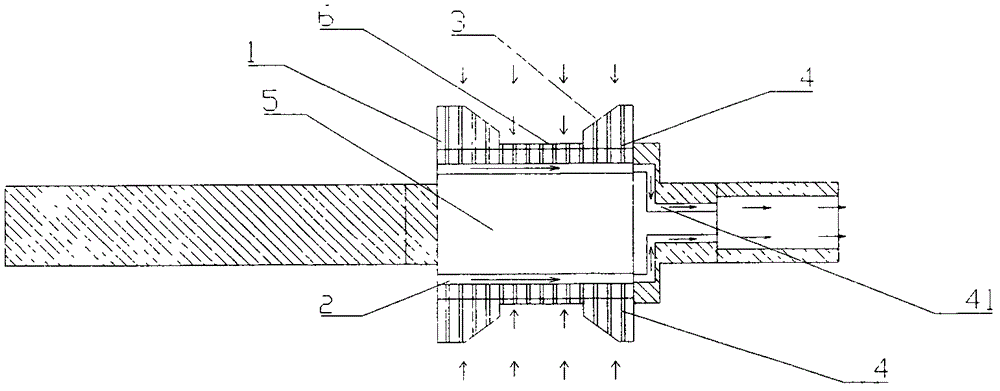

[0042] like figure 1 Shown is the ferromagnetic quenching metal strip coiling device of the present invention, the device includes a housing 1, an axially opened cavity is provided inside the housing 1, and the housing 1 can be powered Driven to rotate continuously in the axial direction, the power drive device can be selected as a motor or the like. A first groove 3 is provided on the housing 1 along the circumferential direction of the housing 1, and a circle is arranged along the circumferential direction, that is, in the axial direction. The width of the bottom end of the first groove 3 is greater than or equal to the The width of the quenched metal strip, the width of the opening end of the first groove 3 is greater than the width of the bottom end, and the width of the first groove 3 is gradually increasing from the bottom of the groove to the opening end; in this implementation In an example, the first groove 3 is selected to be an inverted trapezoid, and the bottom en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com