Active round-flow four-way water mixing heat exchange valve

A technology for heat exchange valves and circumvention, applied to multi-way valves, valve details, valve devices, etc., can solve the problems of large water flow noise and resistance, inaccurate and inconvenient control of outlet flow and water temperature, and reduce mechanical vibration , The effect of energy saving is obvious, and the effect of preventing direct impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

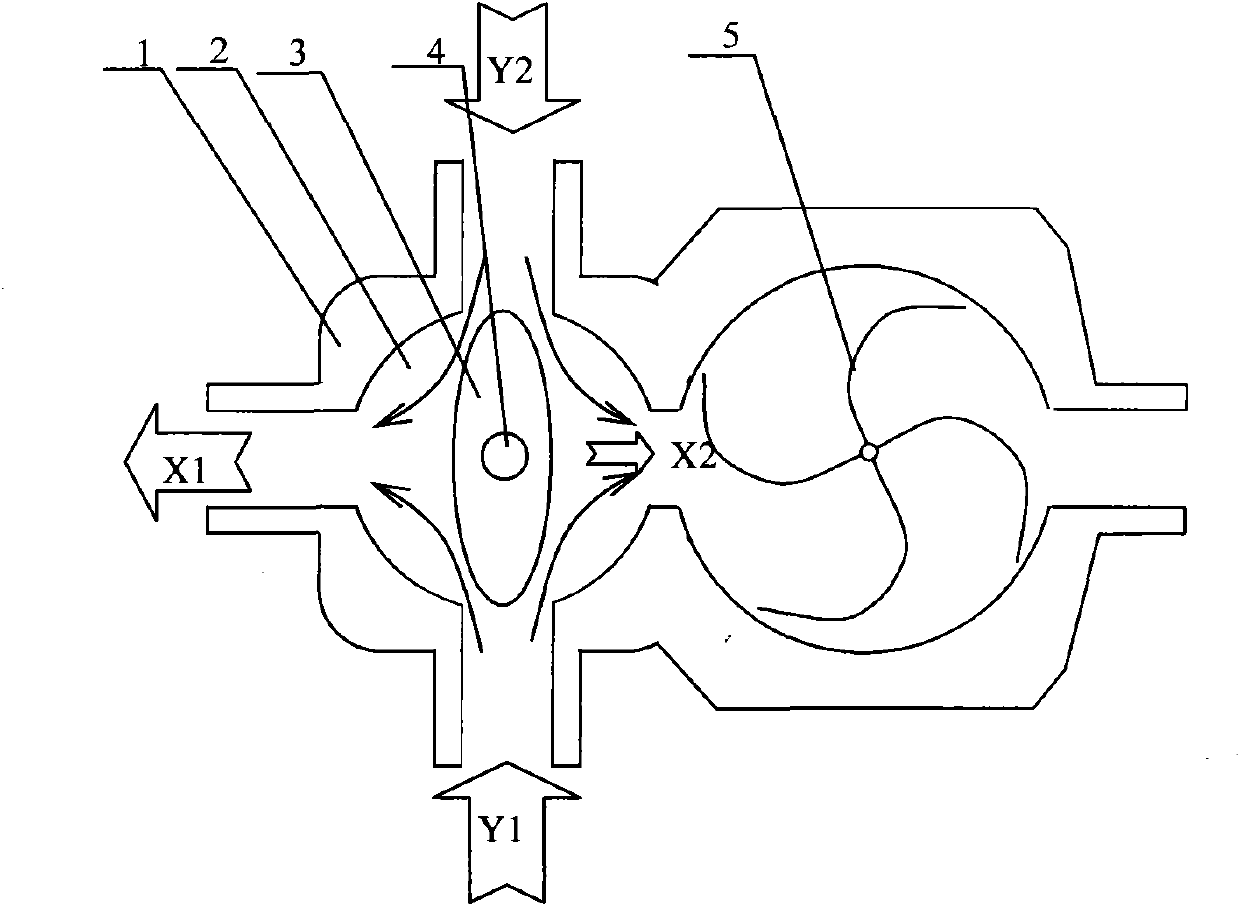

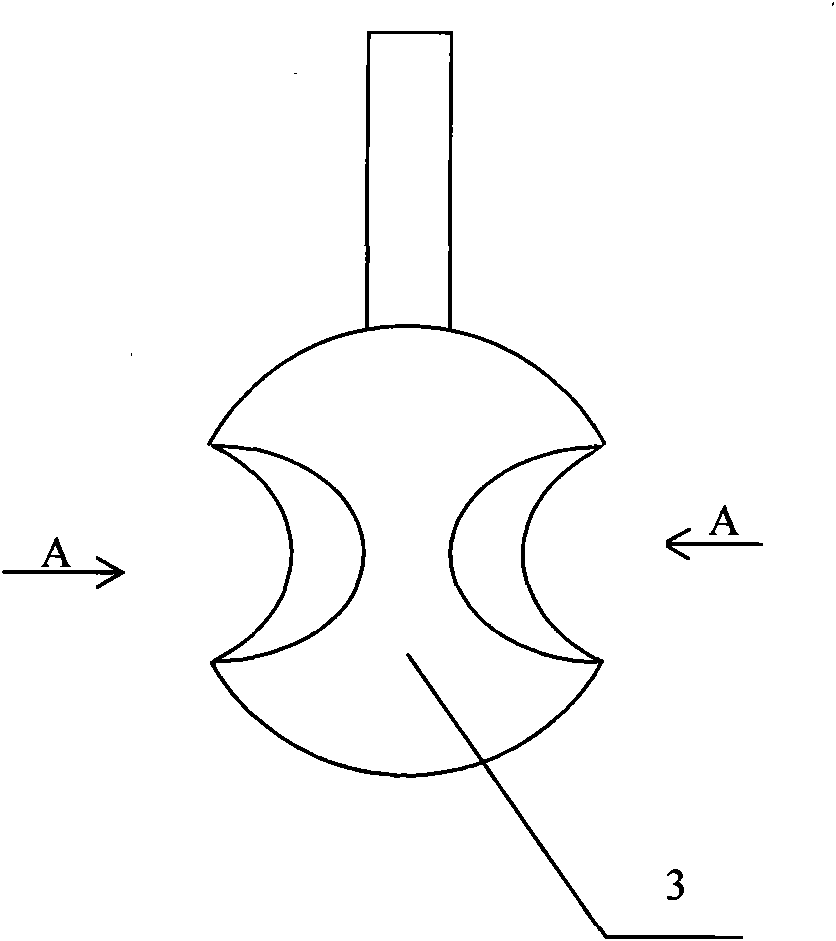

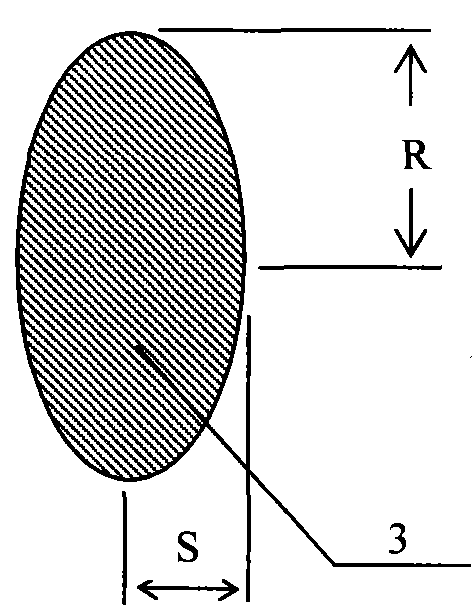

[0011] Embodiment 1: The hollow part of the valve casing 1 has a valve cavity 2, and the valve cavity 2 communicates with four openings to the outside of the valve casing 1, perpendicular to the plane where the centerlines of these four openings are located, and passing through the four openings. The intersection point of the centerlines is fixed The flow-circling plate 3 is fixed on the valve shaft 4 in the valve chamber 2. The flow-circulating plate 3 is spherical, and there is an open arc-shaped groove on the local outer edge. The middle section of the flow-circulating plate 3 is elliptical. The connecting part on the inner wall is provided with an elliptical water inlet, which cooperates with the open arc-shaped groove on the outer edge of the spherical flow-around plate 3, and the connecting part forms an approximately circular through hole.

[0012] The cross-section of the middle part of the flow-circling plate 3 is smooth and protruding in four outward directions with l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap