Three-axis linkage numerical control welding machine

A three-axis linkage, welding machine technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of equipment tension, affecting product quality, uncontrollable welding seam shape, etc., to facilitate producers and improve production efficiency Effect

Inactive Publication Date: 2011-06-15

GUANGDONG ZHONGBAO KITCHENWARE

View PDF2 Cites 38 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If a variety of products are produced in the same period, it will inevitably cause equipment tension; second, the profiling method can only follow the plane curve, such as the X-axis and Y-axis are shot at the same time, then the Z direction can only be ignored. gun

If the welding torch is close to the welding wire in the Z direction and away from the welding wire in the Z direction, the welding current acts on the welding place differently, and the shape of the final weld seam will also be uncontrollable

This is a flaw in the welding of the spout and the body, which seriously affects the quality of the product

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

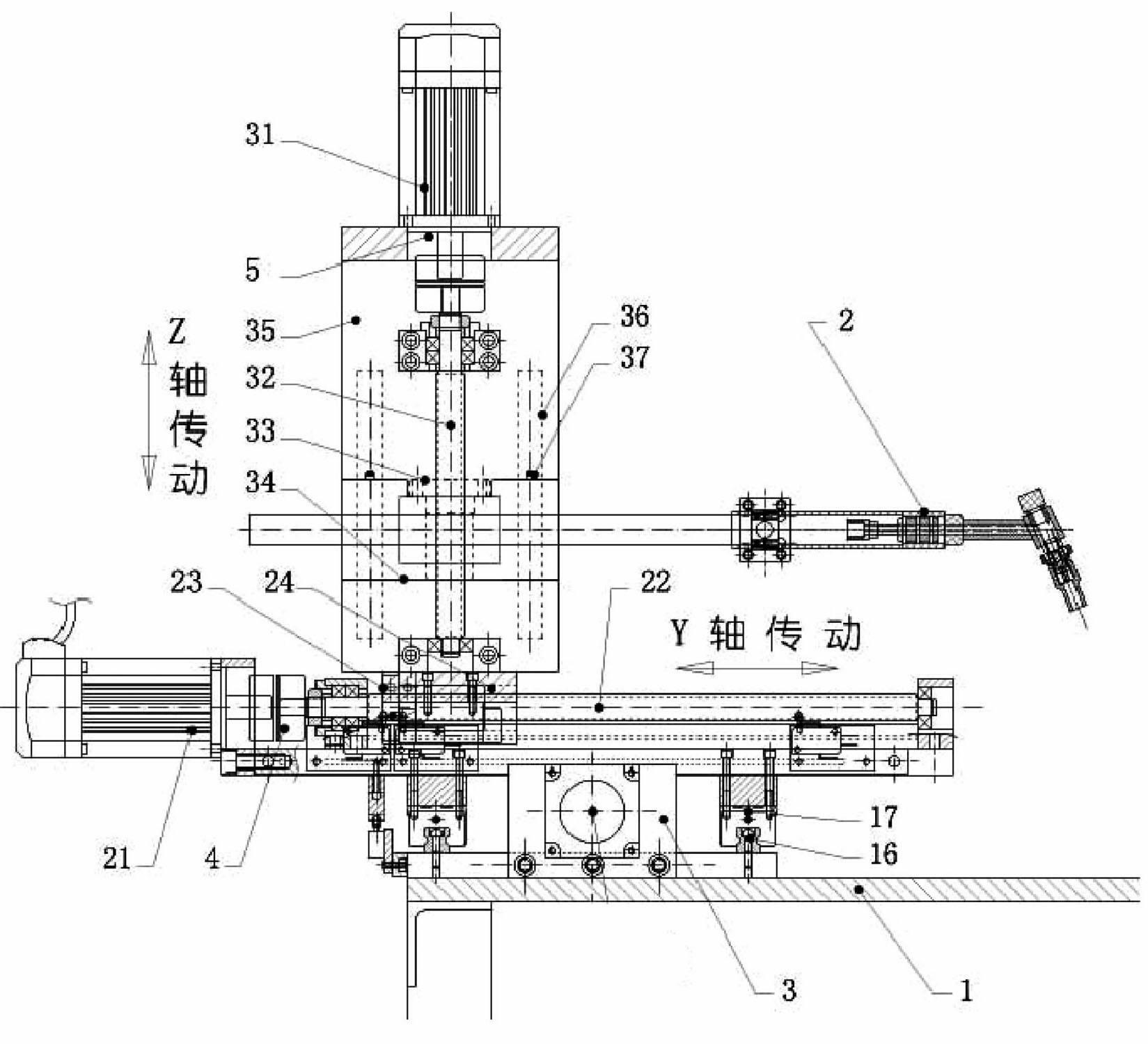

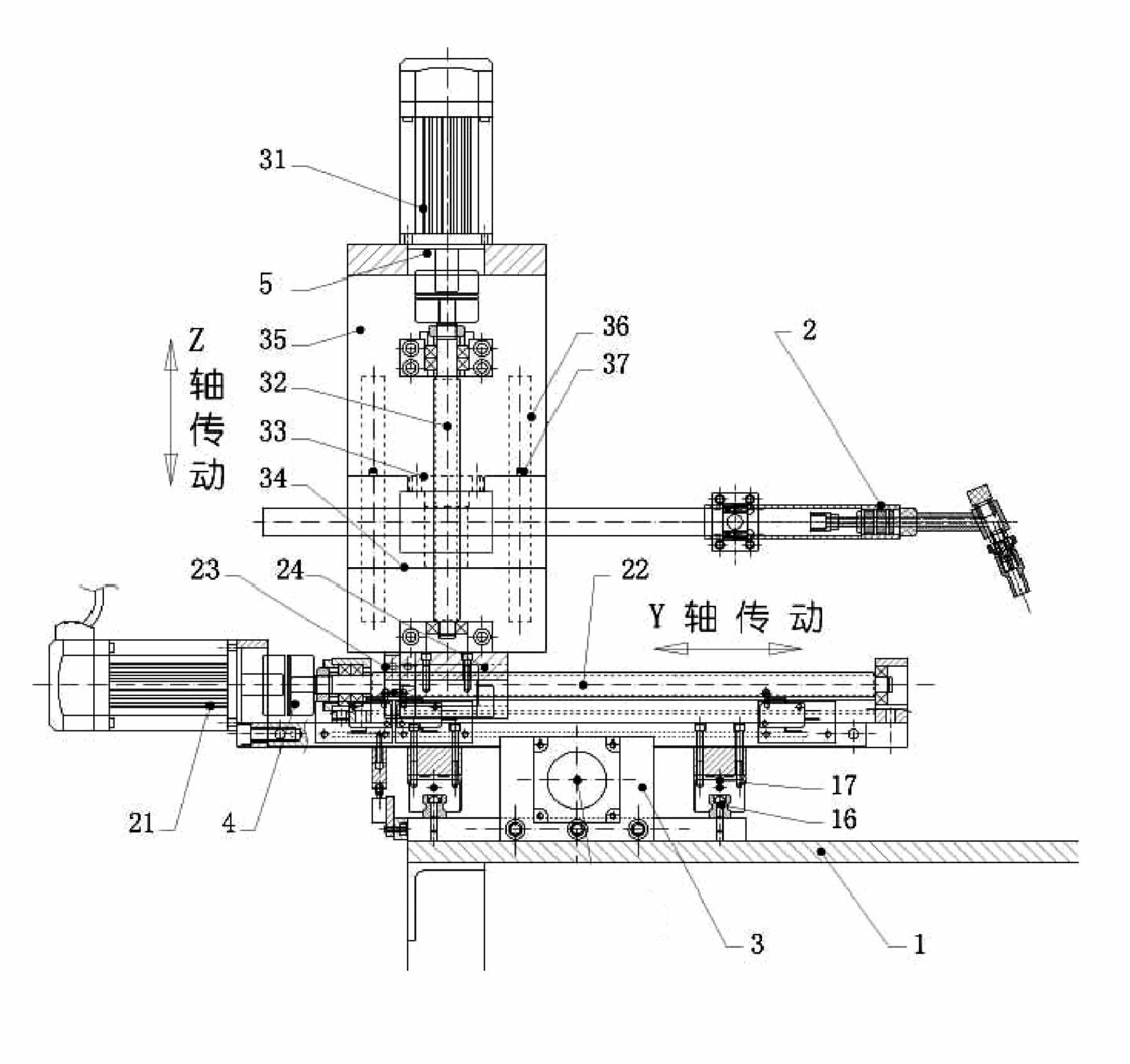

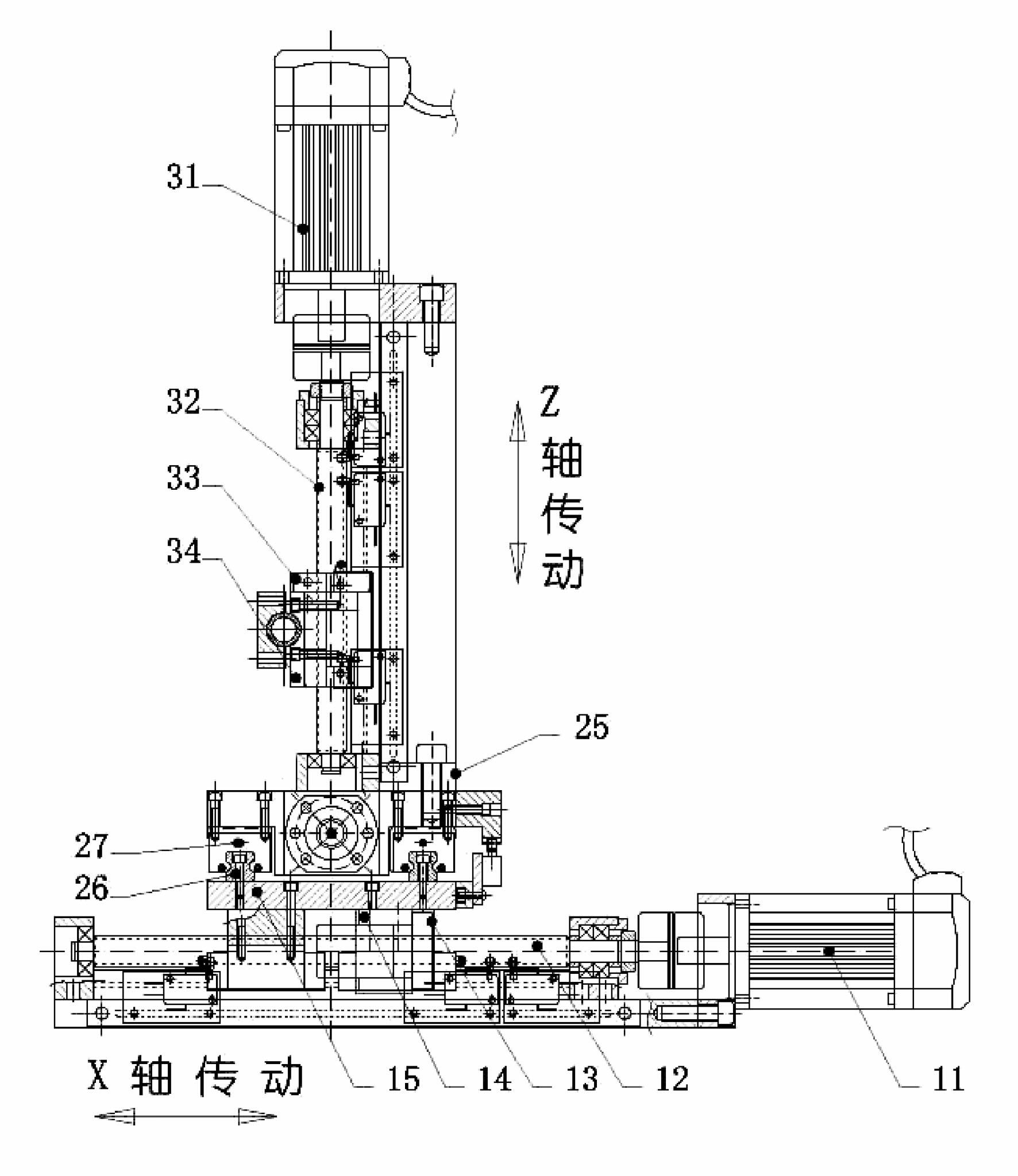

The invention discloses a three-axis linkage numerical control welding machine, which comprises a frame and a welding gun, wherein the frame is provided with a three-axis driving mechanism; the welding gun is arranged on the three-axis driving mechanism; and the three-axis driving mechanism drives the welding gun to a pointed position according to a received control instruction. In the three-axis linkage numerical control welding machine, the driving mechanism capable of independently moving along X, Y and Z axes according to externally input instructions is arranged, so that the welding gun moves in a three-dimensional direction and can complete the welding work according to the preset spatial curve; therefore, great convenient is provided for producers, and the production efficiency is improved.

Description

A three-axis linkage numerical control welding machine technical field The invention relates to a welding machine, in particular to a numerically controlled welding machine with X, Y, and Z three-axis linkage functions. Background technique Most of the current welding machines only have a simple welding function, that is, under the manual operation of the welder, the welding torch is placed on the welding place to complete the welding. Take welding stainless steel kettles as an example. In the production of stainless steel kettle products, the spout and the kettle body were welded. The most primitive method in the past was manual operation—the worker held a welding torch and welded along the junction curve of the spout and the kettle body. This original craft method requires not only skilled workers, but also their dedicated working attitude. This will inevitably result in the limitations of its application and the high requirements for labor and the inefficiency of prod...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K9/12B23K37/02

Inventor 林能超

Owner GUANGDONG ZHONGBAO KITCHENWARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com