Dryer outside swing door device

A dryer and swing door technology, applied in drying chambers/containers, dryers, etc., can solve the problems of poor maintainability, reduced service life of the door, complex structure, etc., and achieve convenient maintenance, simple structure, stable and reliable work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

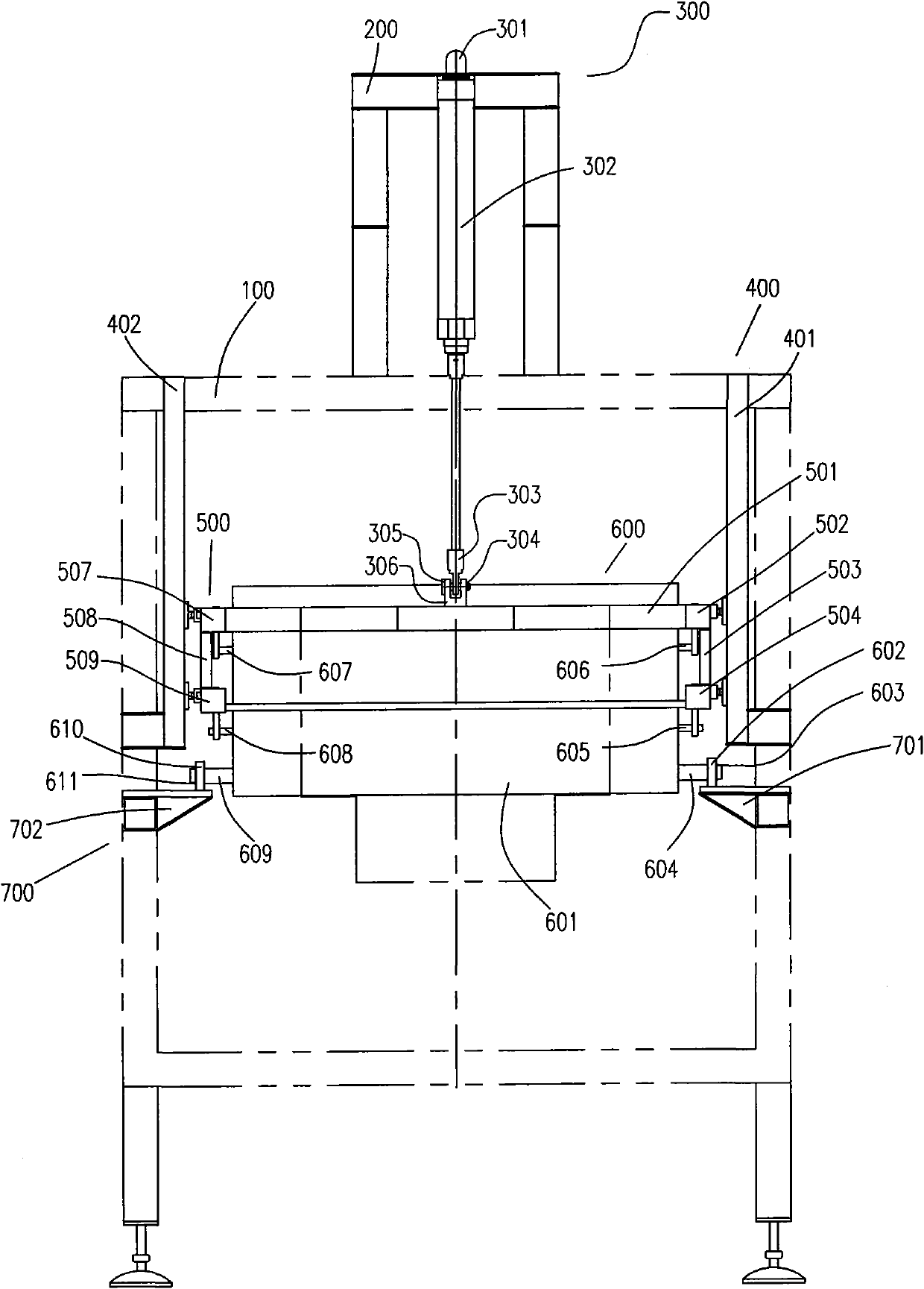

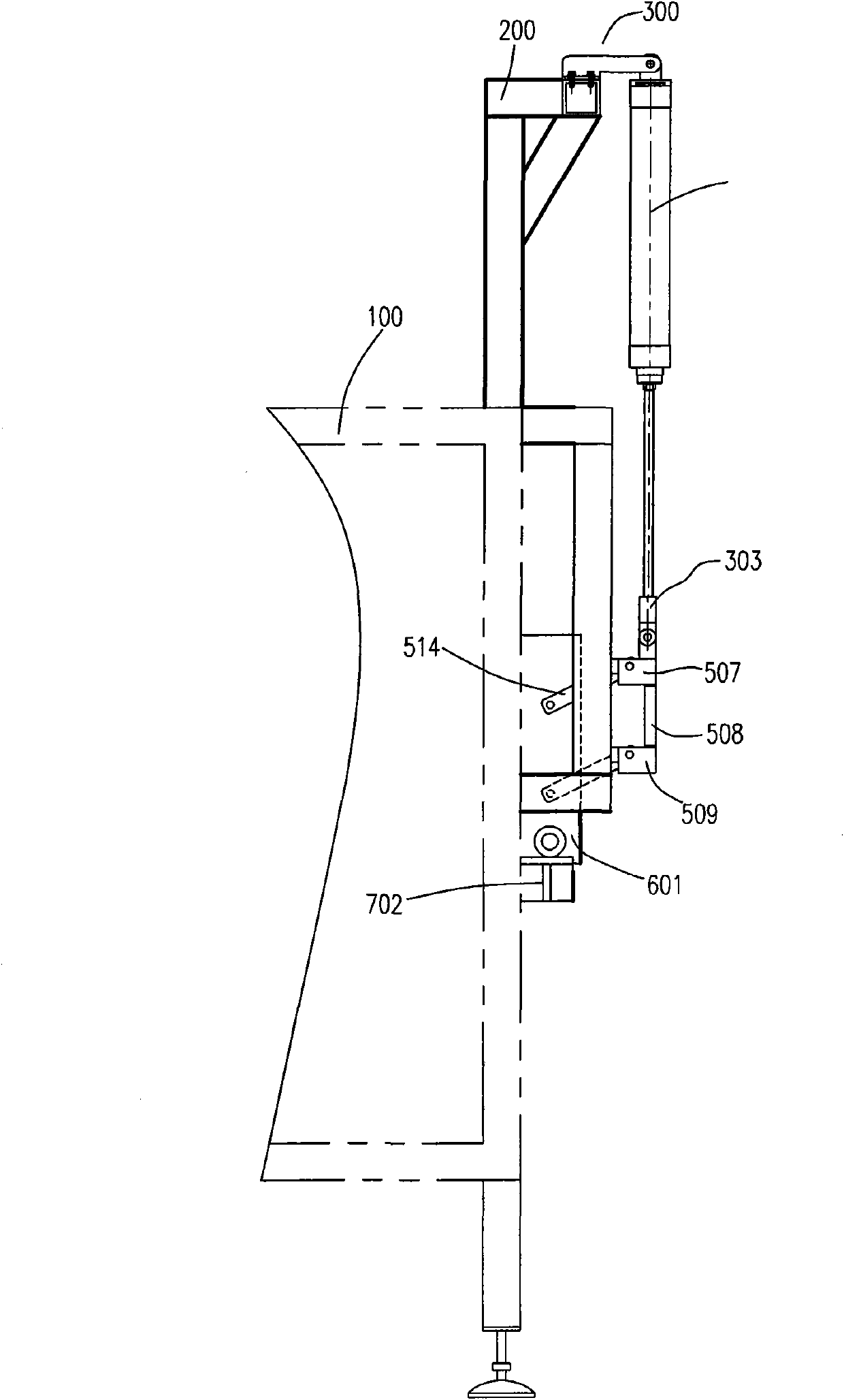

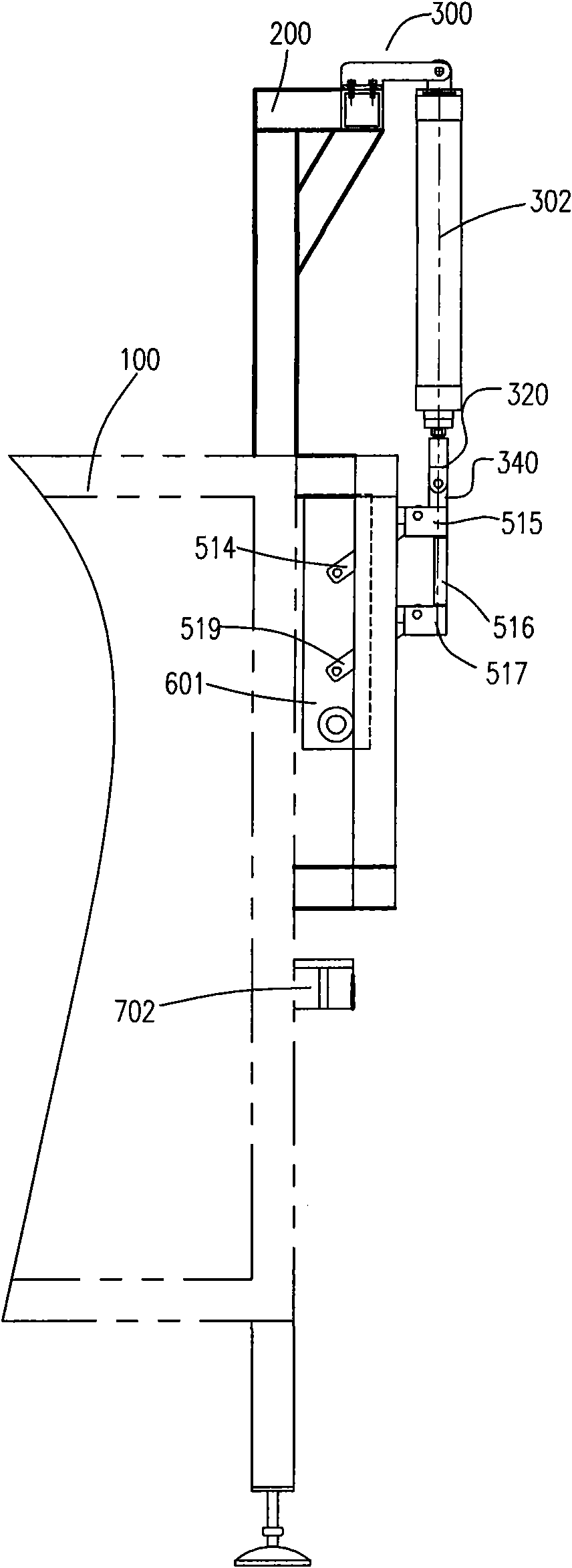

[0027]The outer swing door device of the dryer includes a cylinder frame (200) which is arranged on the dryer (100) and is fixed with a cylinder driver (300). The inner wall of the dryer (100) is provided with guide rails (400) The matching device door swing mechanism (500) also includes a device door (600) that can move vertically up and down on the guide rail (400) and is connected with the device door swing mechanism (500) and is arranged on the device door (600). ) under the pallet (700). The swing-out mechanism (500) of the device door comprises a swing-out crossbeam (501) rigidly connected with the swing-out connector (306) of the cylinder, and the swing-out crossbeam (501) is rigid to the upper right special-shaped block (502) and the upper left special-shaped block (507) respectively. Connection; the upper right special-shaped block (502) is connected with the upper right crank (513) through the upper right connecting pin (515) and cotter pin (522), the upper right spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com