Anti-twisting washer clamp and special washer seat thereof

A washer seat and washer technology, which is used to measure the direction of torque/torsional force when tightening, can solve the problems of reducing the probability of washer rotation, destroying the integrity of the sample, and not being able to completely ensure that the washer is fixed. It achieves convenient operation and excellent structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

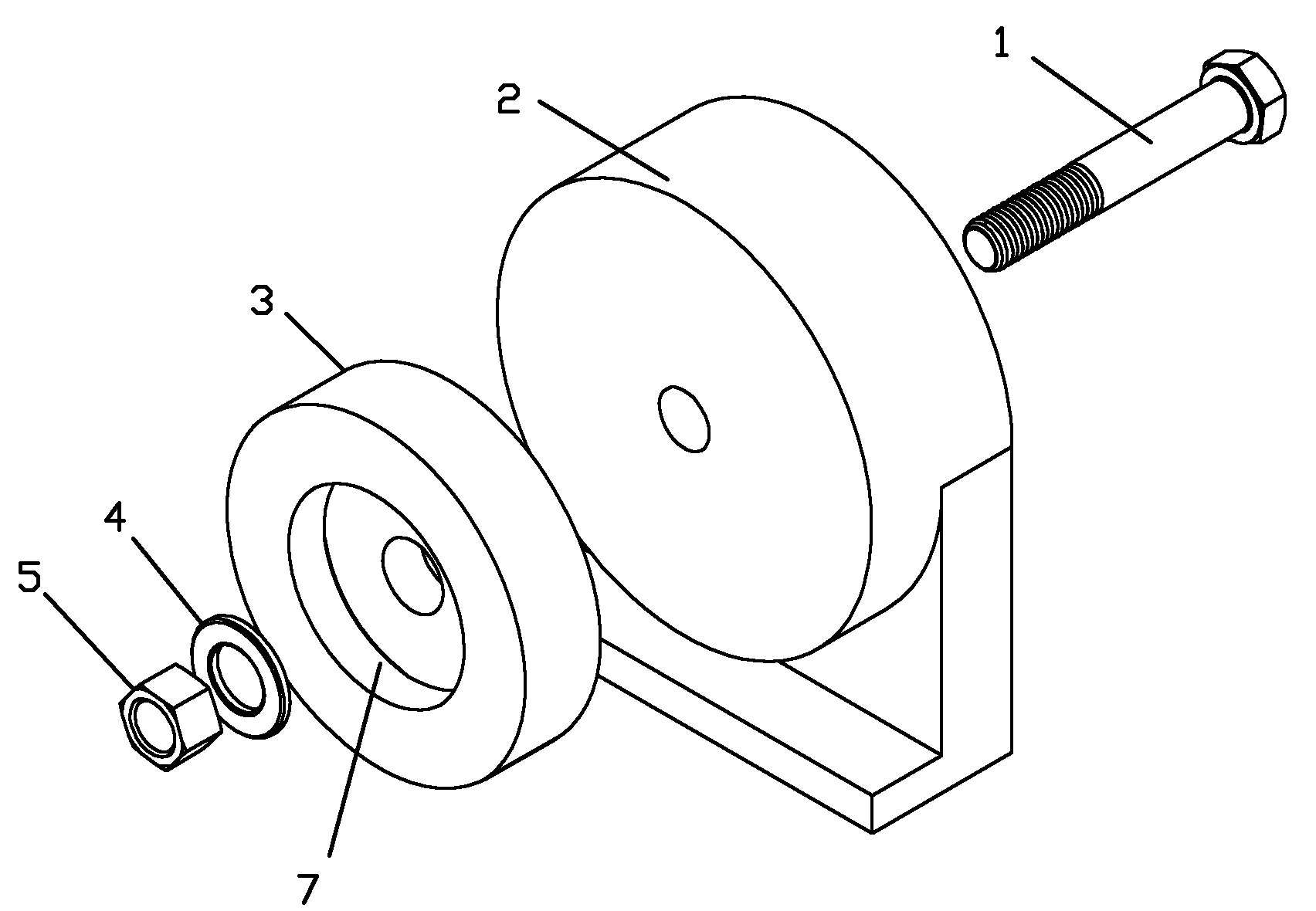

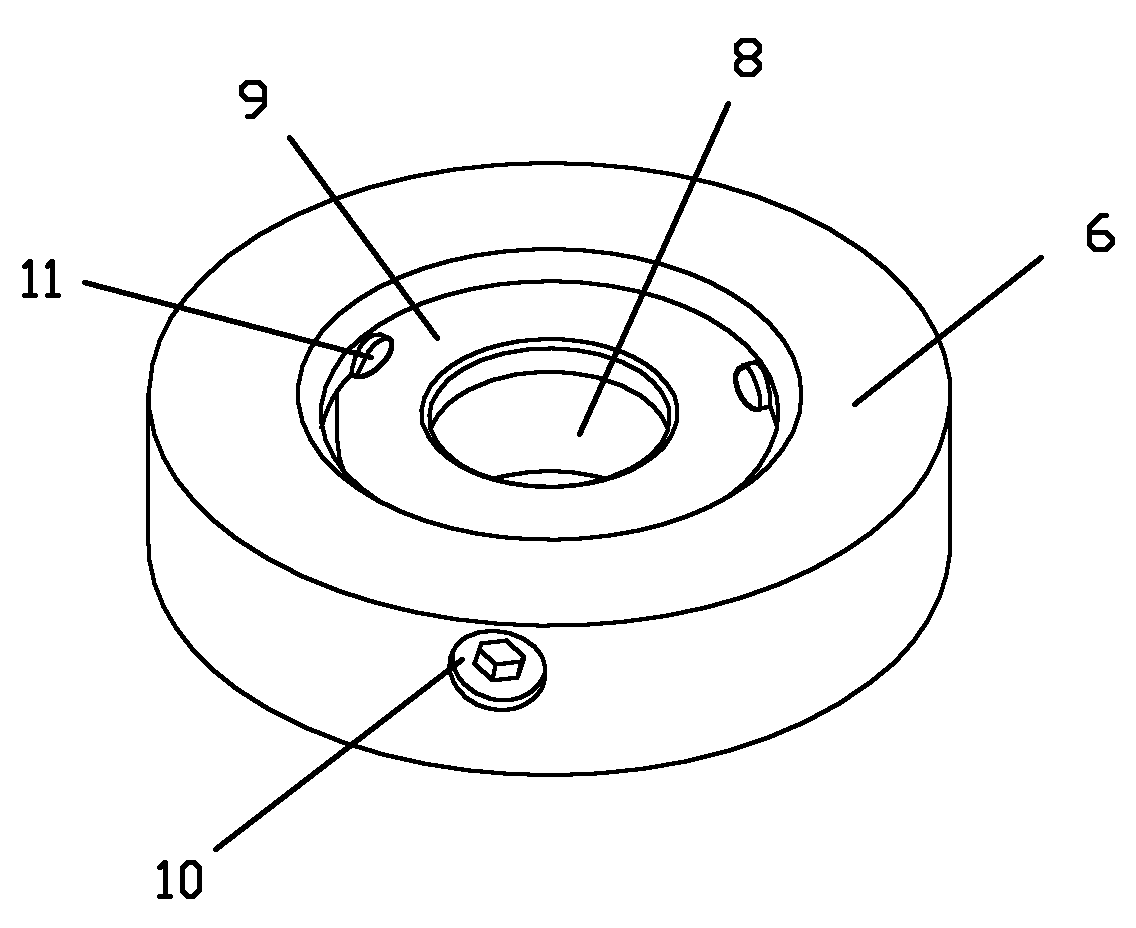

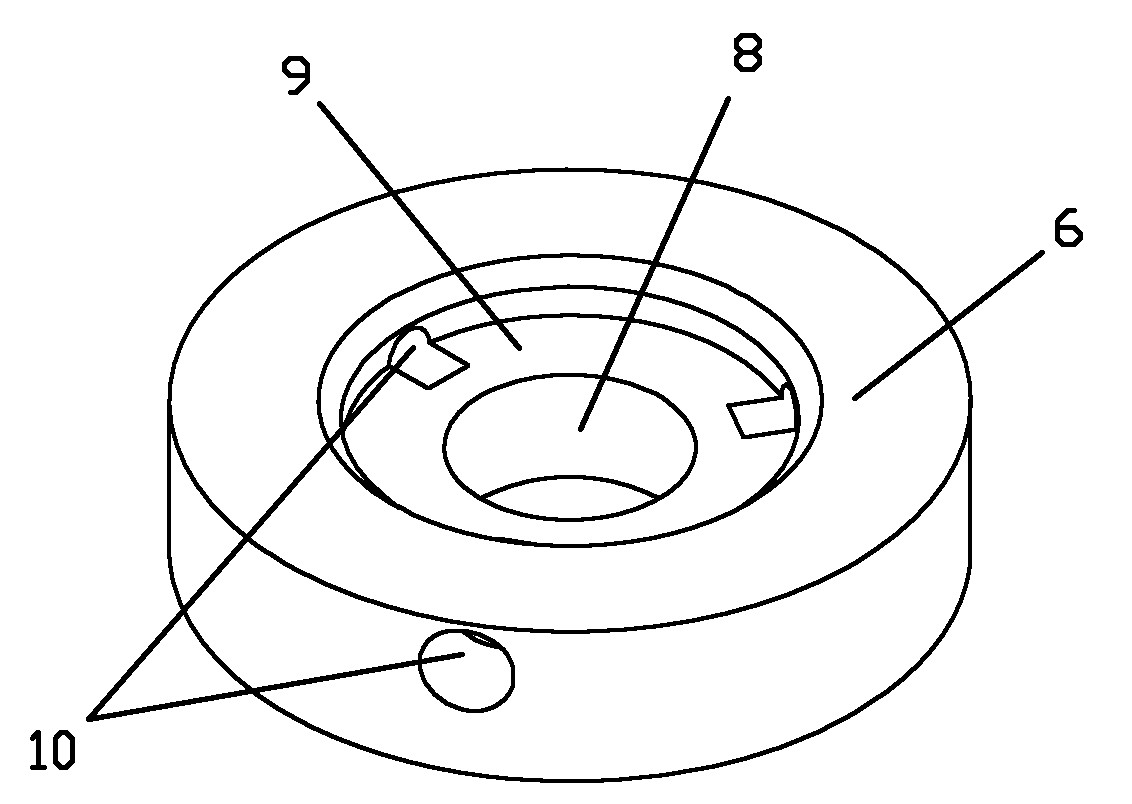

[0021] refer to figure 2 , 3 , the washer anti-twist clamp of the present invention includes a washer seat 6, and the washer seat 6 is provided with a central hole 8 and a circular groove 9 for placing the washer, and three circular grooves are evenly arranged on the circumferential surface There are radial positioning holes 10 through which fixed hexagonal bolts 11 are arranged in the positioning holes 10 . The outer diameter of the washer seat 6 is slightly smaller than the inner diameter of the accommodating groove 7 of the measured bolt fixing fixture 3 .

[0022] refer to Figure 4 , 5 , Place the washer 4 in the circular groove 9 of the washer seat 6, and tighten the fixing hex bolt 11 to fix the washer 6.

[0023] refer to Figure 6 , the installation process of the tested sample before the torque test is as follows:

[0024] First pass the head of the bolt 1 through the central hole of the sensor 2 and the bolt fixing fixture 3 from the outside, then the fixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com