Lens barrel forming mold

A technology for forming molds and lens barrels, which can be used in installation, optics, instruments, etc., and can solve problems such as difficulty in ensuring the coaxiality of lens barrels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

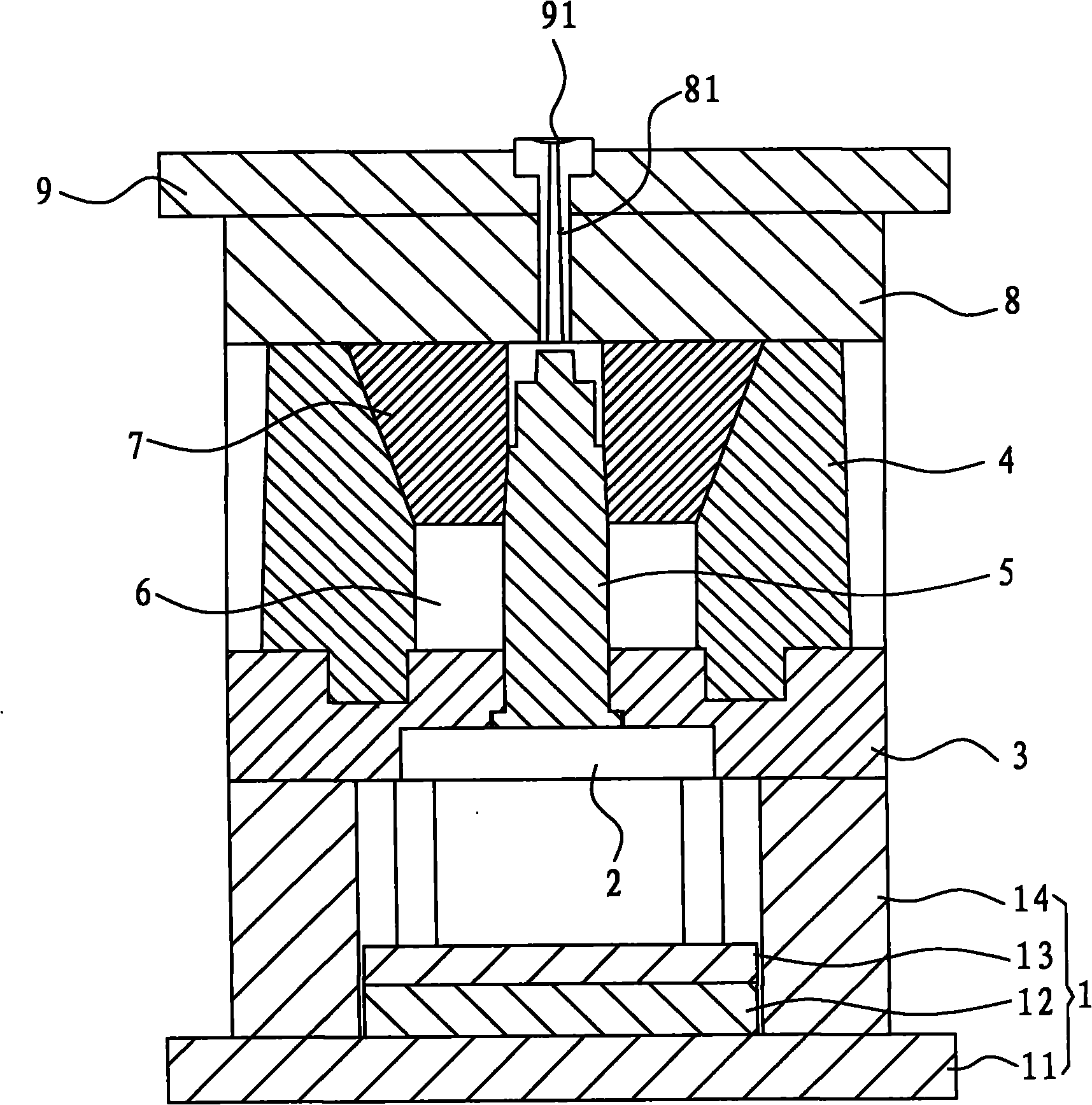

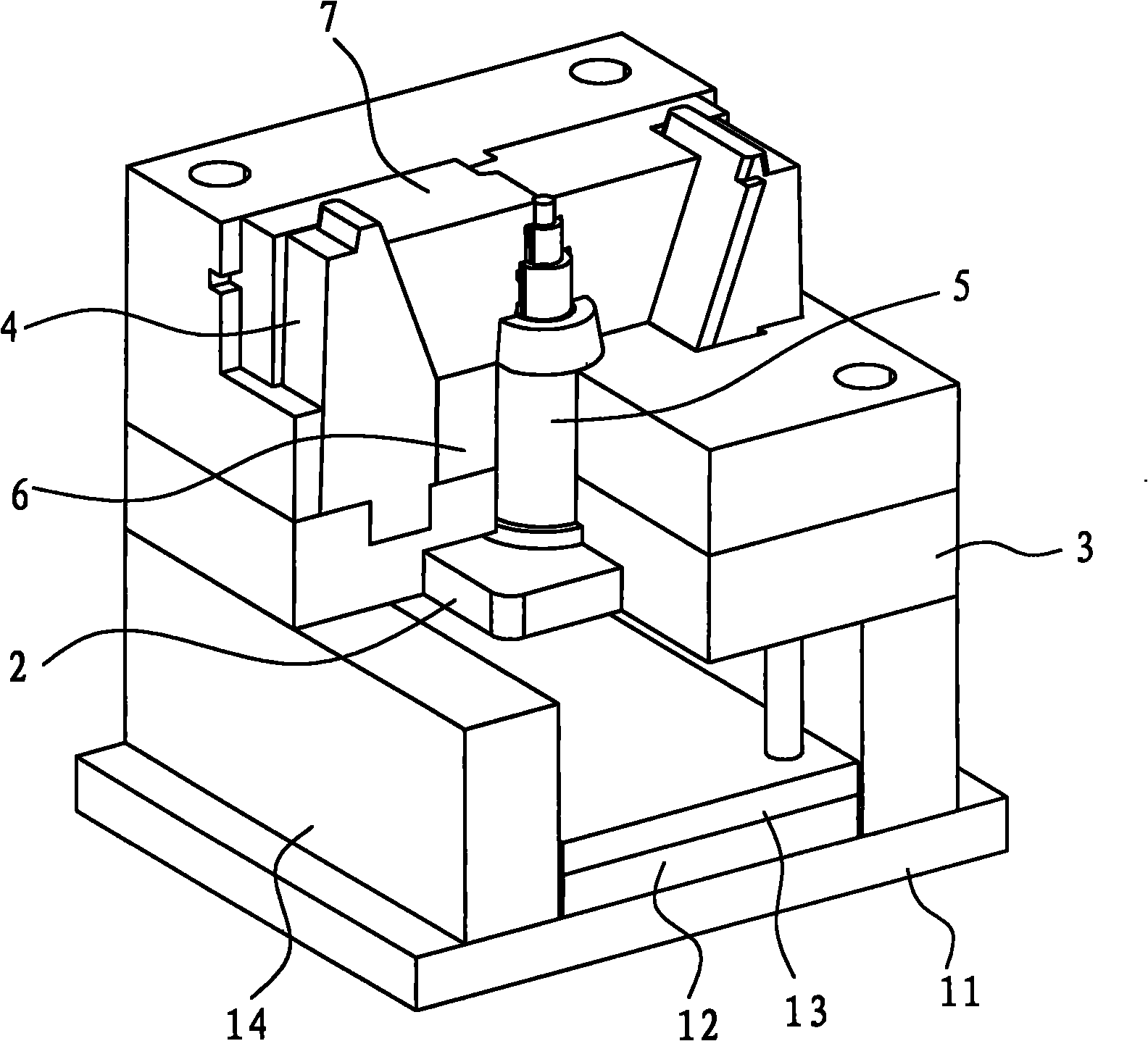

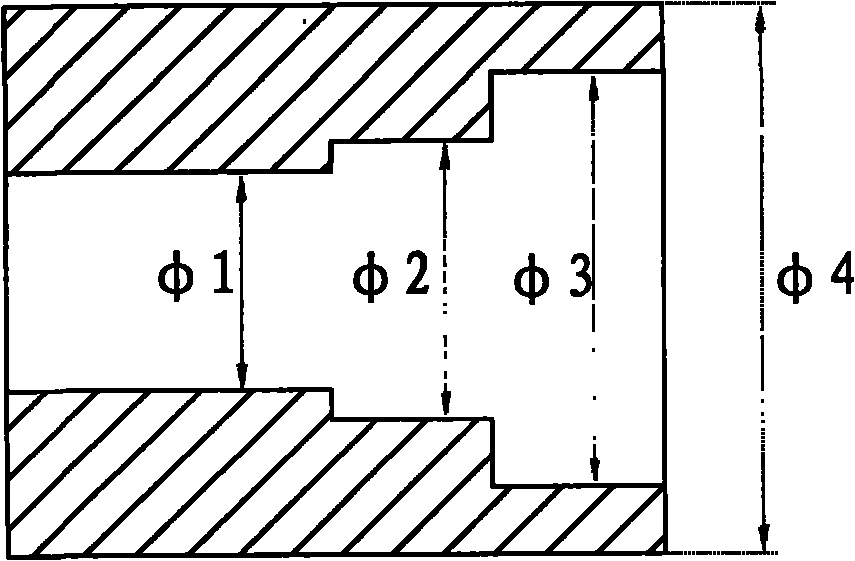

[0010] refer to Figure 1 to Figure 3 , the embodiment discloses a lens barrel forming mold, which includes a bottom plate 11, a bottom needle plate 12, a face needle plate 13, a square iron 14, a supporting plate 2, a B plate 3, two briquetting blocks 4, a mold core 5, a stripper Plate 6, two row blocks 7, A plate 8 and I-shaped plate 9, the bottom needle plate 12 is set on the bottom plate 11, the face needle plate 13 is set on the bottom needle plate 12, and the square iron 14 is set on the bottom plate 11 Above, the bottom plate 11, the bottom needle plate 12, the face needle plate 13 and the square iron 14 constitute the base, the B plate 3 is set on the base 1, and the supporting plate 2 is set between the B plate 3 and the base 1 to support Hold the mold core 5, the stripping plate 6 is set on the outside of the lower circumference of the mold core 5, the two row blocks 7 are cohesively set on the outside of the upper circumference of the mold core 5, and the two pressi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap