Cup for soya-bean milk making machine and soya-bean milk making machine using same

A soymilk maker and cup technology, which is applied in the field of soymilk maker, can solve the problems that the manufacturing cost of soymilk maker cannot be minimized, the cup structure of soymilk maker is complex, and the deflector is not easy to clean, so as to achieve good crushing effect and save diversion Organ structure, the effect of retaining nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

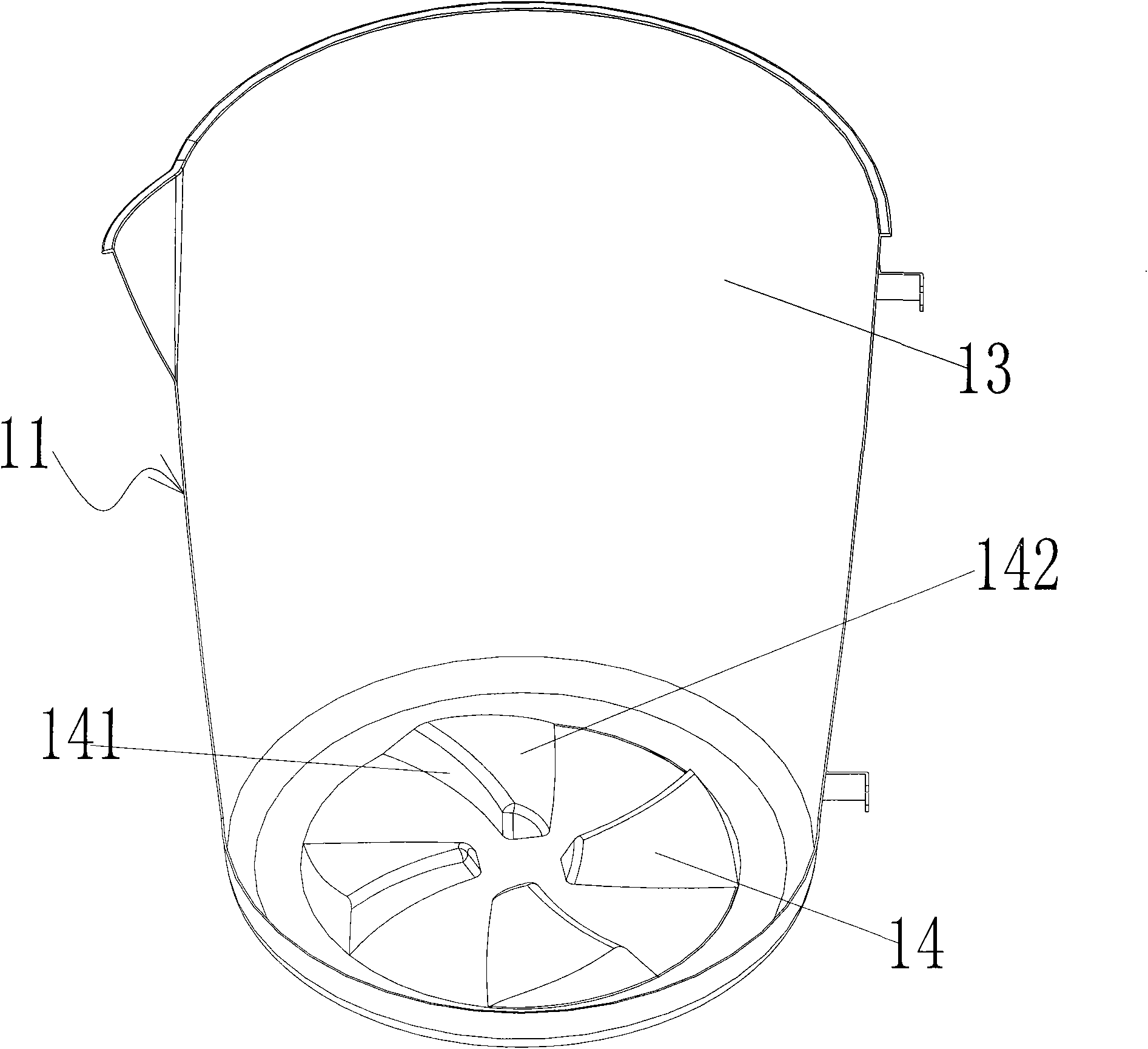

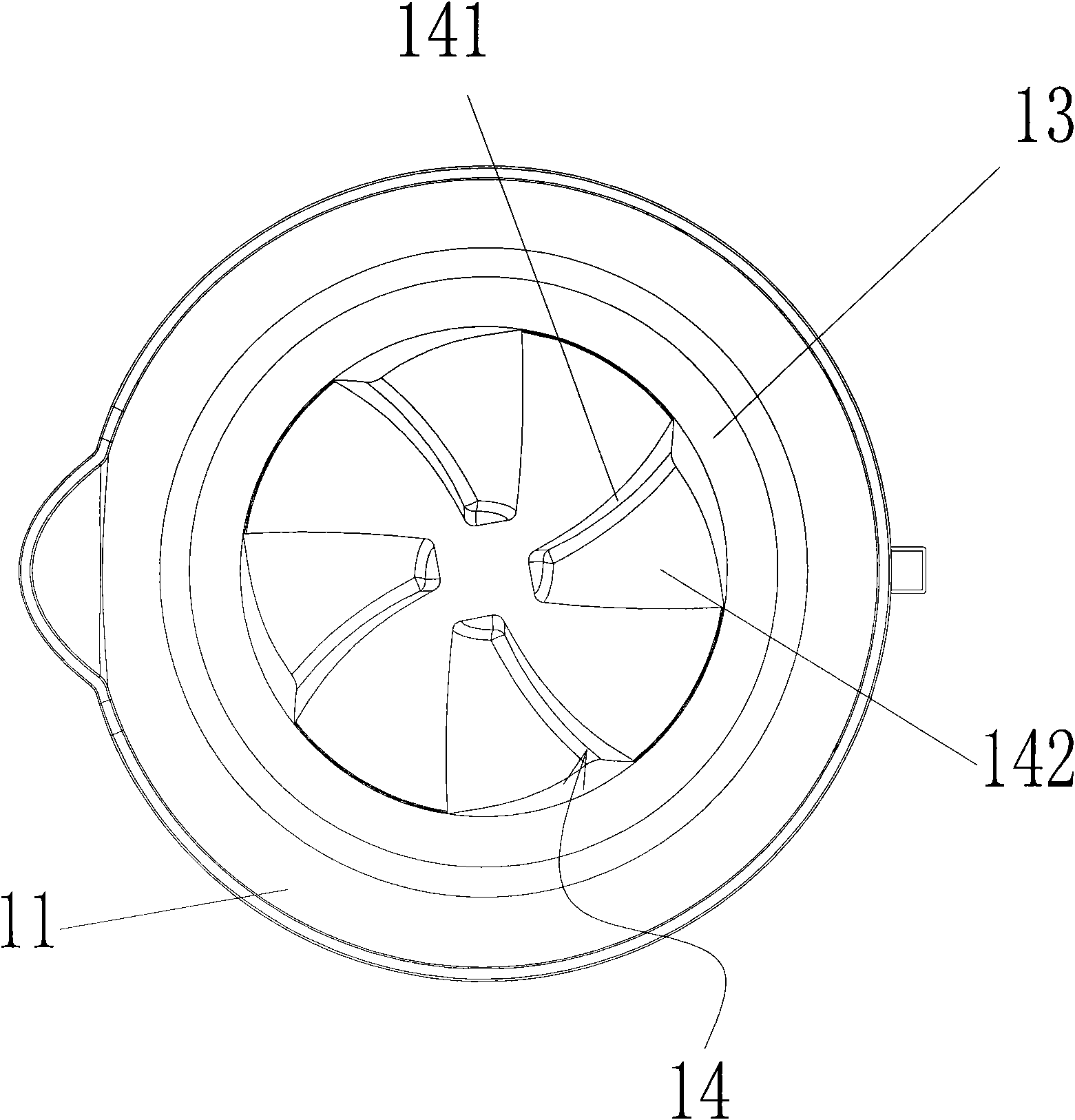

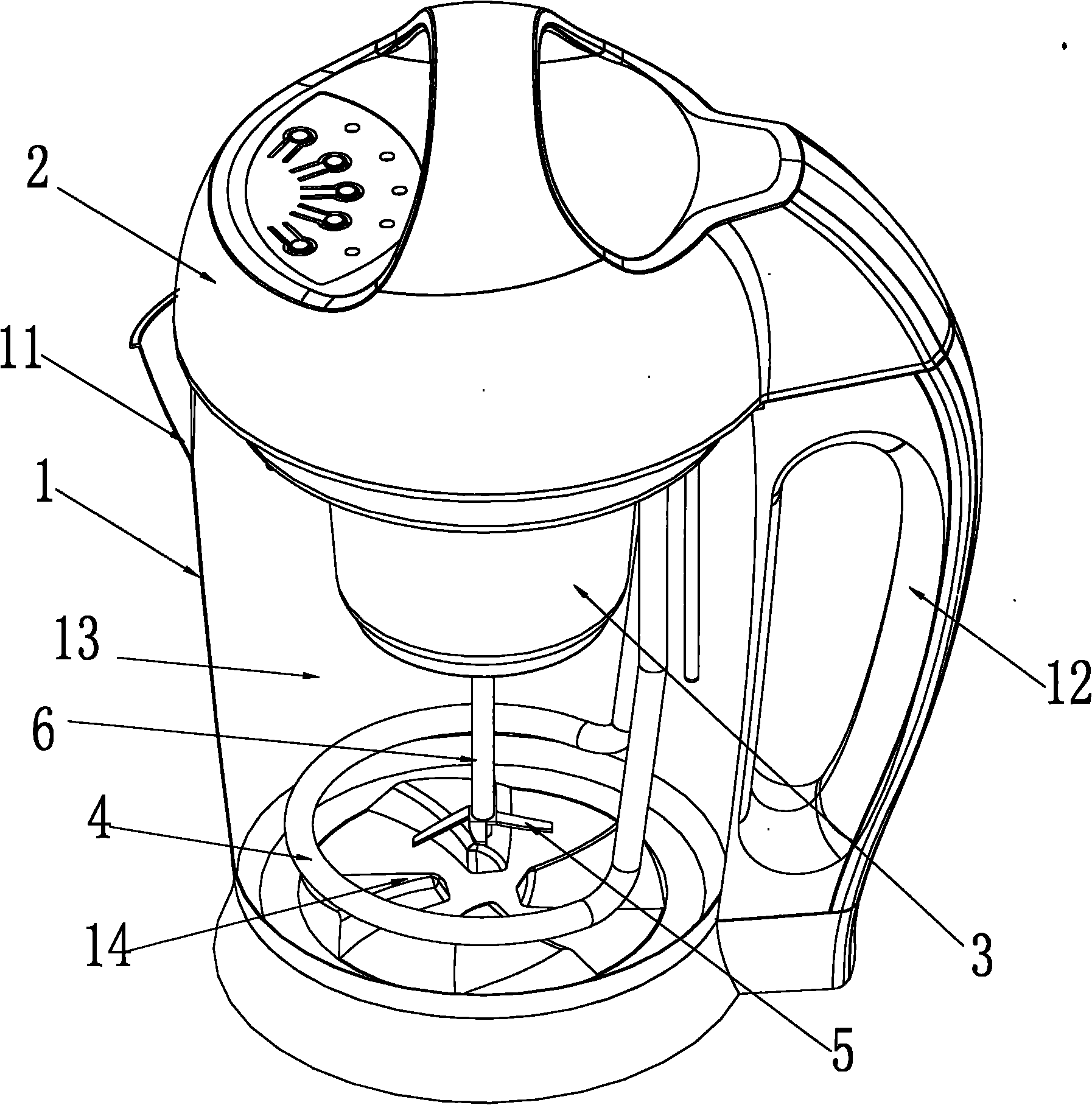

[0026] Embodiment one: if figure 1 , figure 2 , image 3 , Figure 4 As shown, the soybean milk machine of the present invention includes a cup 1 and a cup cover 2 installed on the cup. The cup 1 includes a cup body 11 and a handle 12. A cutting cavity 13 is formed on the cup body 11. Soymilk is arranged in the cup cover 2. Machine control circuit board 8, motor 3, the crushing blade 5 that is installed on the motor output shaft 6, the motor output shaft 6 and the crushing blade 5 stretch into the inside of the cutting cavity 13, at the bottom of the cavity 13, on the bottom surface of the cup body 11 Four guide vanes 14 are protruded, and the crushing blade 5 positioned above the guide vanes 14 rotates to form a forward vortex during operation, while the guide vanes 14 form a reverse vortex. A heat pipe 4 protrudes from the cup cover 2 to the cutting cavity 13, and the heat pipe 4 is electrically connected with the control circuit board 8 of the soybean milk machine. An ...

Embodiment 2

[0027] Embodiment two: if Figure 5 As shown, the difference from Embodiment 1 is that there are three guide vanes 14 on the inner bottom surface of the cup 1 .

Embodiment 3

[0028] Embodiment three: as Image 6 As shown, the difference from Embodiment 1 is that there are five guide vanes 14 on the inner bottom surface of the cup 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com