Physical-means-based ballast water treatment equipment

A technology for treating equipment and ballast water, which is applied in the fields of natural water treatment, light water/sewage treatment, water/sludge/sewage treatment, etc. The effect of increasing the adaptability range and improving the utilization rate of ultraviolet light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

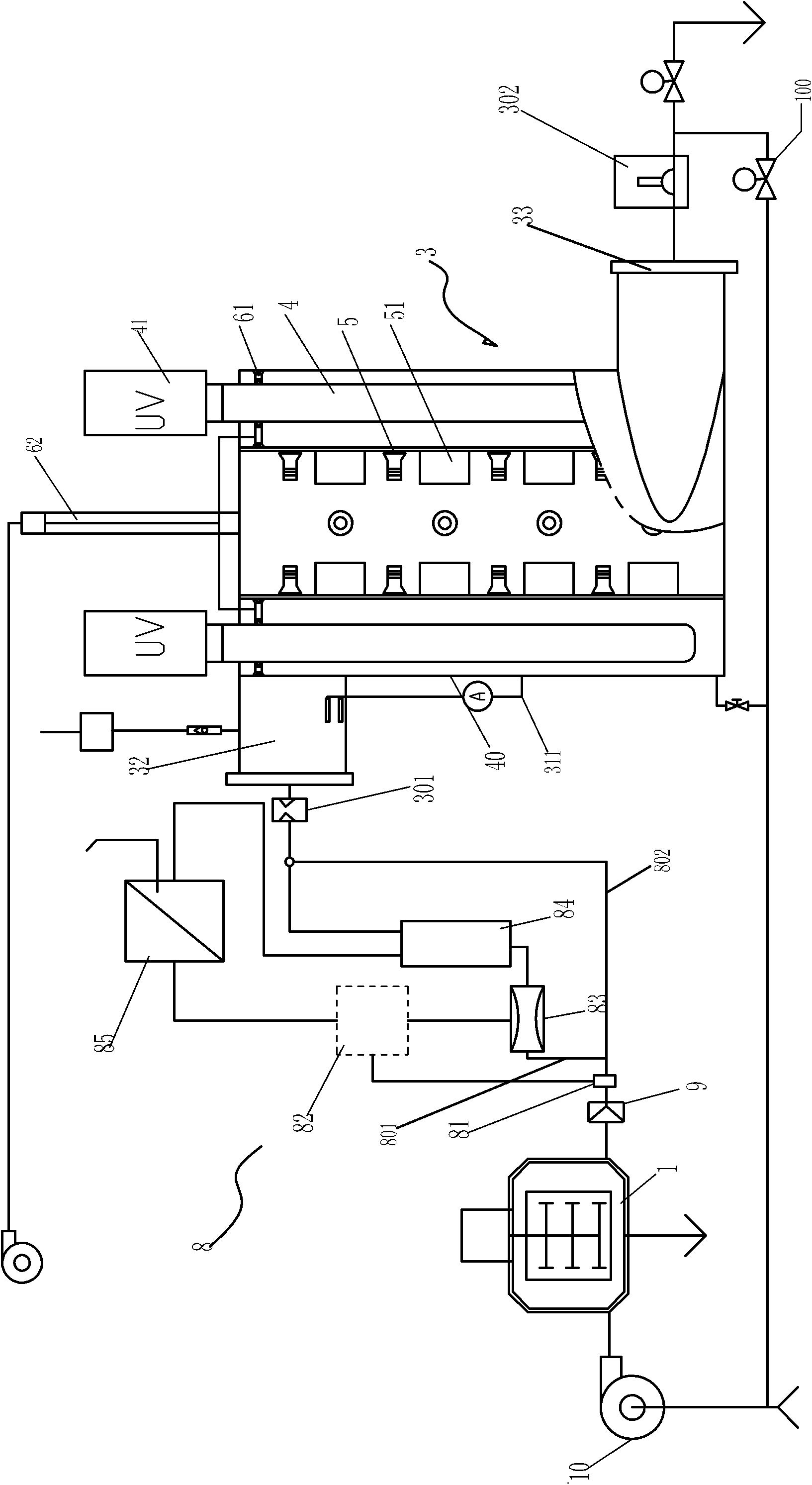

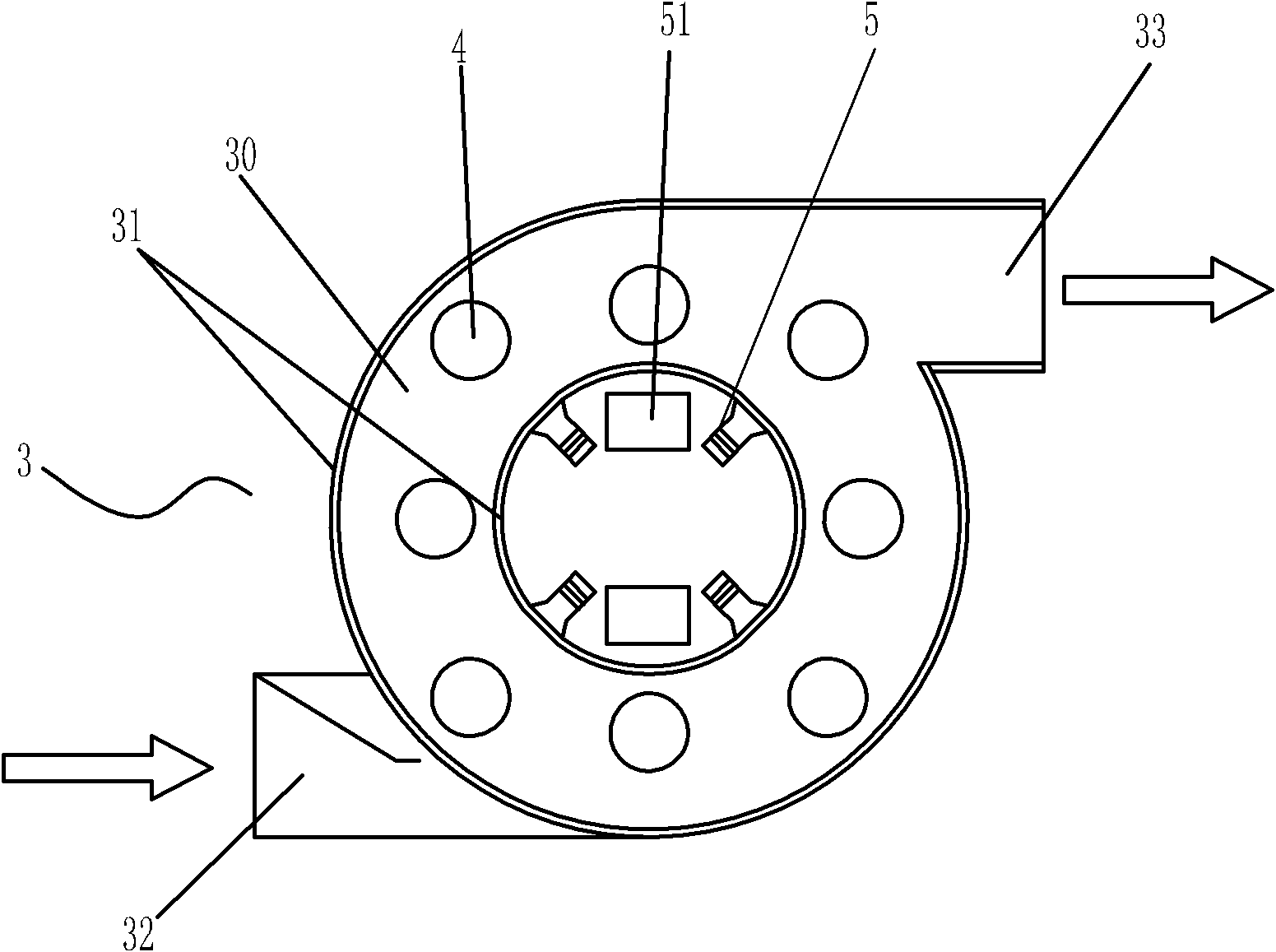

[0032] See figure 1 , the present invention mainly includes: a backwash filter 1, an oxygen supplementary collection mechanism 8 and a combined ultraviolet and ultrasonic processor 3. For ease of description, the present invention will be described in detail according to the flow path of the ballast water.

[0033] The ballast water will be pumped into the water inlet of the backwash filter 1 through the ballast pump 1, and will be preliminarily filtered through the backwash filter 1. Backwash filter is a kind of filter that directly intercepts impurities in water, removes suspended solids and particulate matter in water, and reduces turbidity. Backwash filter 1 is a kind of filter with large flow, low resistance, and automatic backwashing by pressure difference control. The filter device has a filter accuracy of 10-100um. The air microbubbles produced by the microbubble generator can be mixed into the water inlet of the backwash filter 1, the diameter of the bubbles is 1-10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com