Partition

A baffle, carrier technology, applied in the superstructure, engine components, machines/engines, etc., can solve problems such as expensive, time-consuming, improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

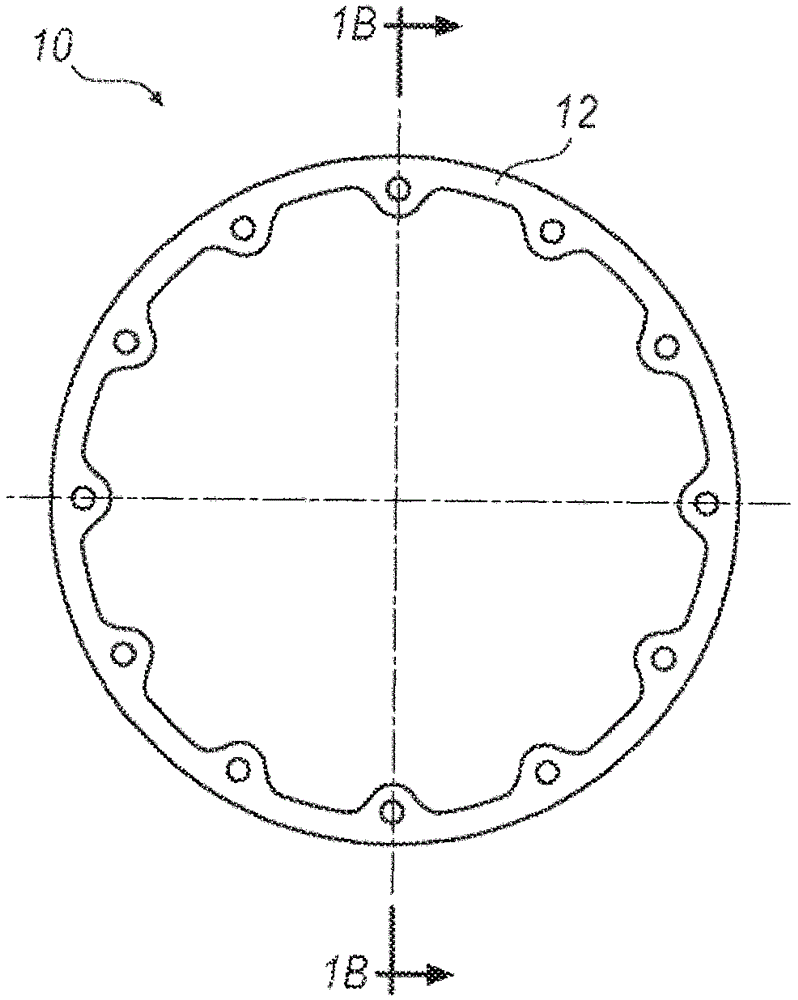

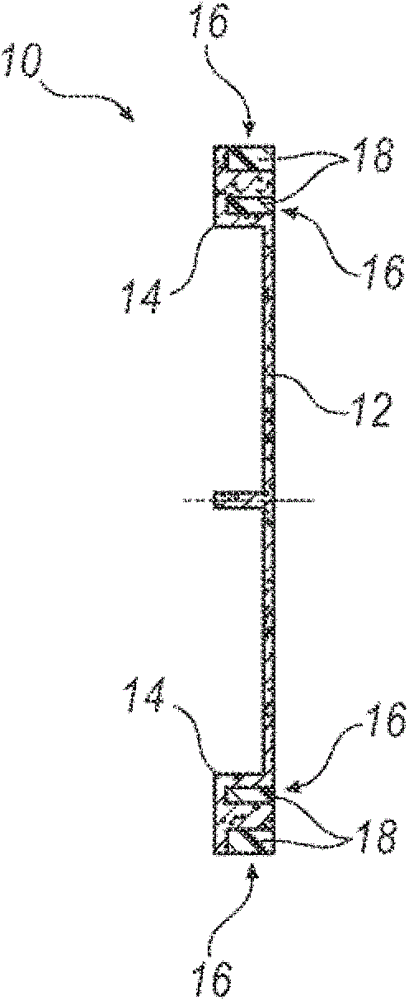

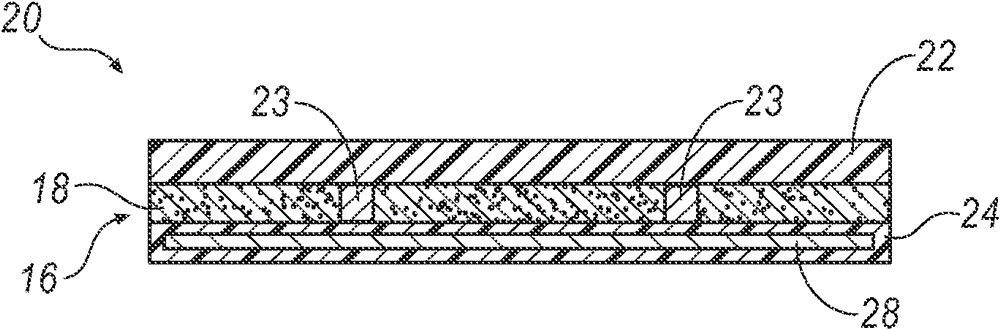

Embodiment Construction

[0015] Baffles can be used to reduce noise and vibration without adding significant weight to the frame. The performance of the diaphragm can be measured by the reduction of noise and vibration, usually by analyzing a specific frequency range. Certain uses may be susceptible to different noise and vibration frequency ranges depending on location, type of vehicle, usage, etc. Baffles can be set to reduce more specific frequency ranges for specific applications. Custom partitions can be achieved by incorporating metal inserts into the partition. The size, shape and / or weight of the metal inserts can be tailored to a particular application in order to alter the performance characteristics of the separator. Modifying the separator by adding and / or changing the size of the metal inserts can greatly enhance the performance of the separator, customizing the separator for a specific application without requiring costly and time consuming tooling changes. Additionally, the outer dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com