Slave cylinder

A shell and piston technology, applied in the direction of fluid-driven clutches, non-mechanical-driven clutches, clutches, etc., can solve problems such as increased friction, reduced service life of slave cylinders, and reduced driving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

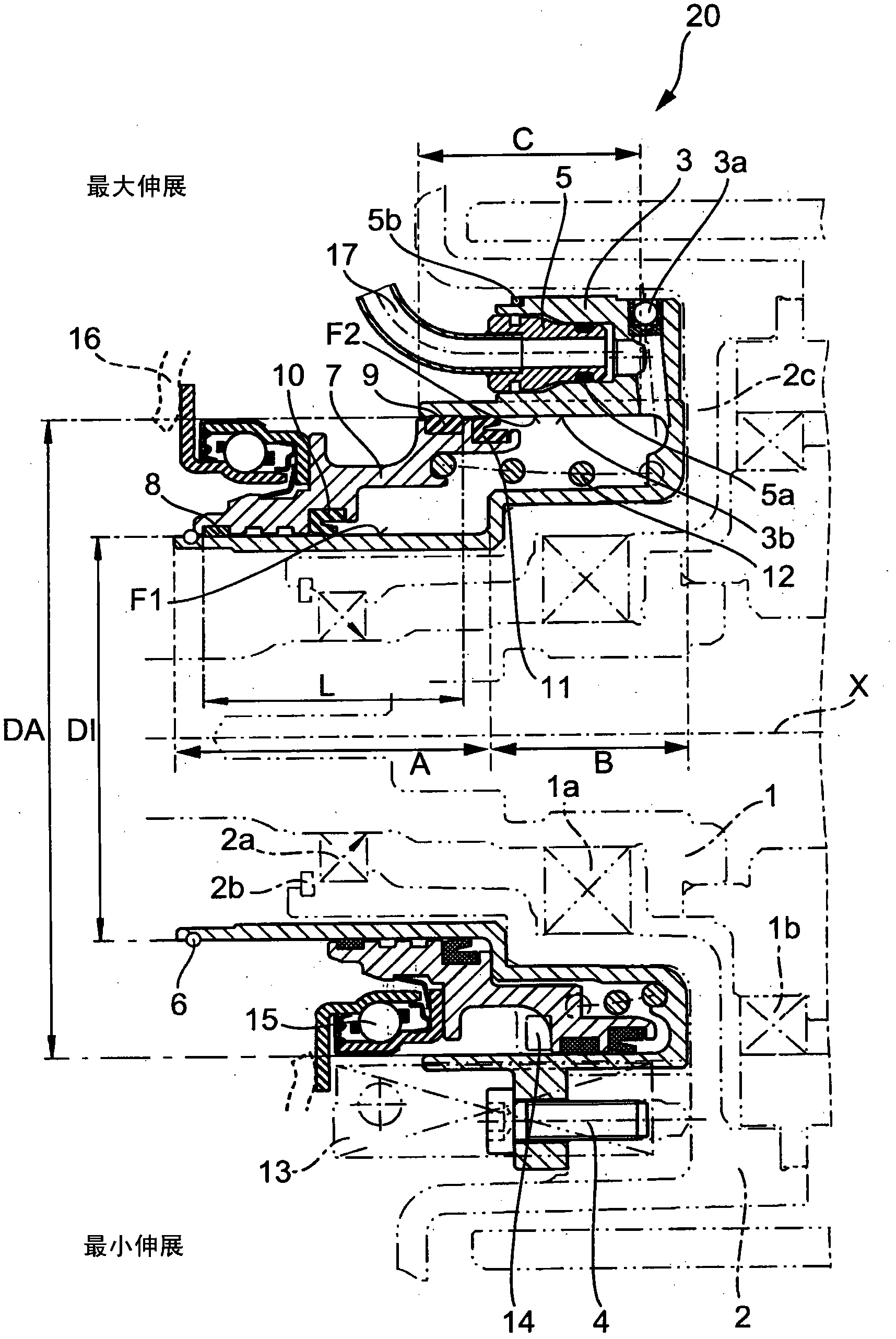

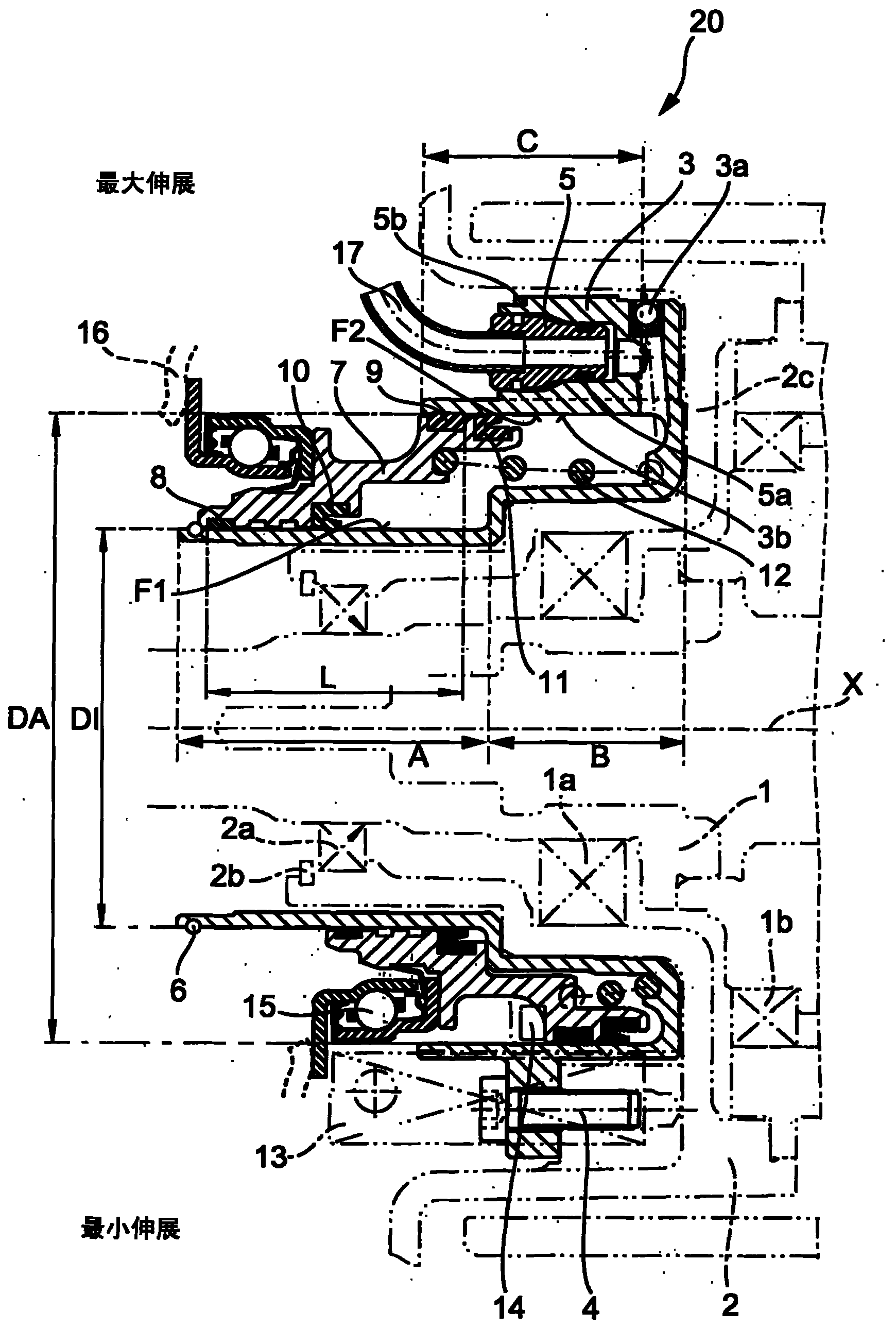

[0011] exist figure 1 The axis of rotation X, which coincides with the axis of rotation of the slave cylinder 20, is used simultaneously to describe the slave cylinder in two disengaged states. The slave cylinder 20 is thus shown above the axis of rotation X in a position of maximum disengagement and below the axis of rotation X correspondingly in a position of minimum disengagement. This slave cylinder 20 is arranged concentrically around the schematically indicated transmission input shaft 1 configured as a hollow shaft, which has two different diameters directly adjoining each other in the area of receiving the slave cylinder 20 , whereby the A sudden jump from one diameter to another forms a step. On this transmission input shaft 1 , a rolling bearing 1 a and a radial shaft sealing ring 2 a are arranged at a distance from one another, wherein the outer ring of the rolling bearing 1 a and the radial shaft sealing ring 2 a are each supported on the bearing flange 2 via th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com