Pretreatment method for freezing freshness keeping of pork

A freezing preservation and pretreatment technology, which is applied in the direction of freezing/cooling preservation of meat/fish, etc., can solve the problems of protein loss, waste of national resources, deterioration, etc., achieve good taste, save acid discharge process, and reduce freezing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

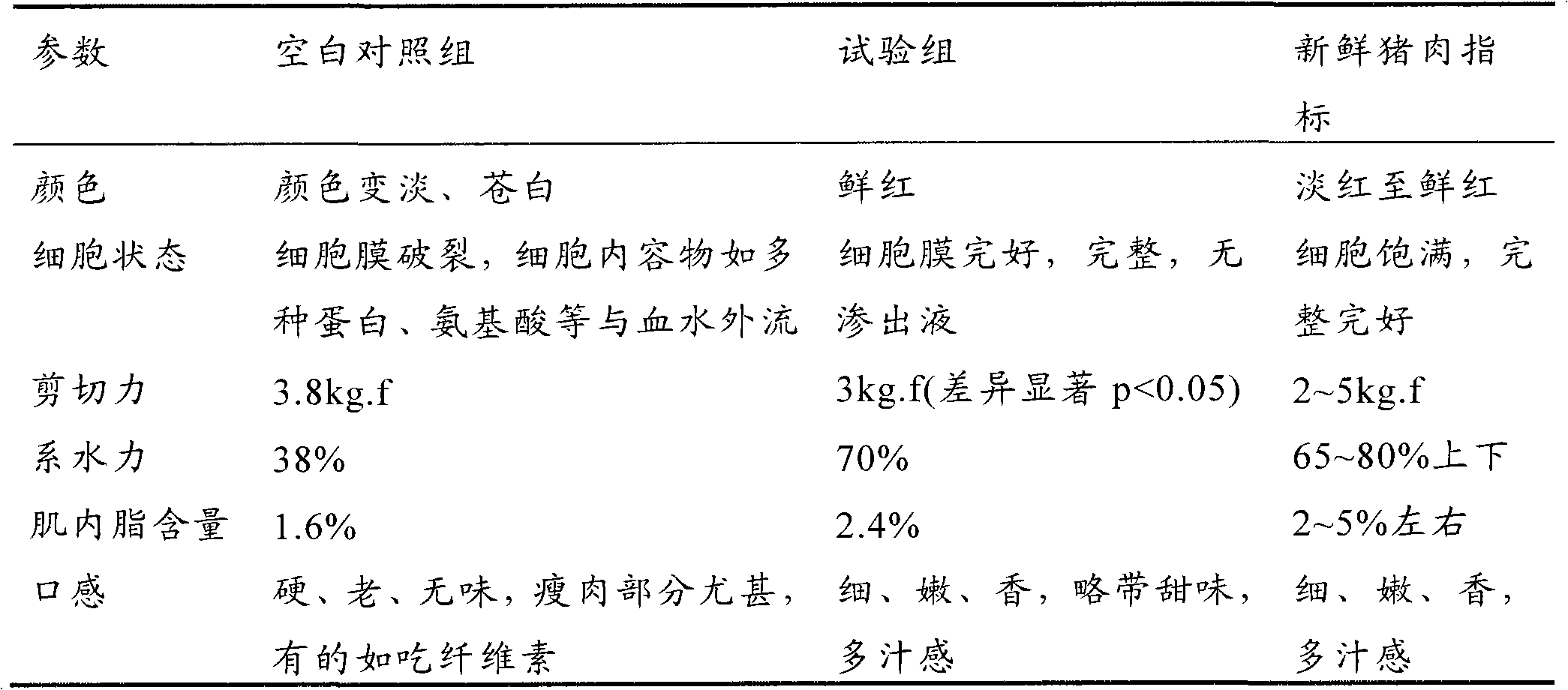

[0013] Cut 35 kg of freshly slaughtered pork into white strips of 350 g each with a thickness of 2.5 cm as the test group. From the WJZ-A200 micro-freezer of Shanghai Jiasheng Biological Products Co., Ltd., quickly freeze for 12 minutes. After freezing, the temperature of the pork center reaches -18°C, then soak in ice water, drain, and then store at -18°C. Store in the freezer for 180 days, then remove and thaw. At the same time, white strips of the same quantity, size and shape just after slaughter were used as a blank control group without being frozen in a micro-freezing liquid, and were directly placed in a -18°C freezer, frozen by cooling air conduction, stored for 180 days, and then taken out to thaw. Observe the color of pork with naked eyes, observe the state of cells with a microscope, and measure parameters such as shear force, water retention and intramuscular fat content of pork with conventional methods. And test pork taste with blind test method, the results ar...

Embodiment 2

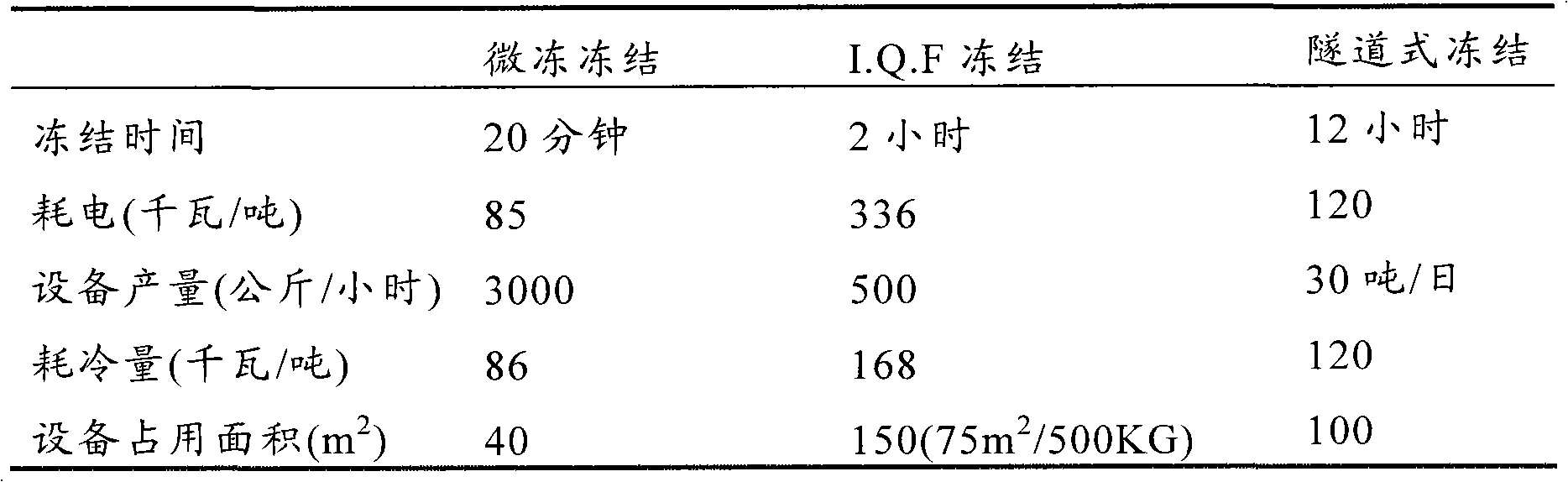

[0018] In the meat processing HACCP workshop, the use of micro-freezing liquid to freeze pork and the I.Q.F freezing in the prior art, tunnel freezing and subsequent freezing and fresh-keeping pork are compared in terms of freezing time, electricity, output, labor, etc., as shown in Table 2 .

[0019] Table 2 Comparison of microfreezing liquid freezing with I.Q.F freezing and tunnel freezing

[0020]

[0021]

[0022] Conclusion: the pretreatment method of the micro-frozen pork of the present invention can shorten the freezing time, save energy by 40%, reduce labor force, and increase the daily production capacity by 3 times compared with conventional freezing.

Embodiment 3

[0024] Cut 35 kg of freshly slaughtered pork into white strips of 350 g each with a thickness of 2.5 cm, and place the central temperature at room temperature in a WJZ- In the A200 type micro-freezer, quickly freeze for 10 minutes. After freezing, the temperature of the pork center reaches -20°C, then soak in ice water, drain, and store in a -20°C freezer for 180 days, and then take it out and thaw it for consumption.

[0025] Conclusion: The color of the pork after being frozen and thawed with micro-freezing liquid is bright red, and it looks like it was just slaughtered; after tasting, it tastes delicious and has a complete color and fragrance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com