Pretreatment method for freezing freshness keeping of pork

A freezing preservation and pretreatment technology, applied in the direction of preservation of meat/fish through freezing/cooling, etc., can solve the problems of protein loss, inedible, and national resource allowances, etc., to reduce freezing costs, taste good, and save acid discharge process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

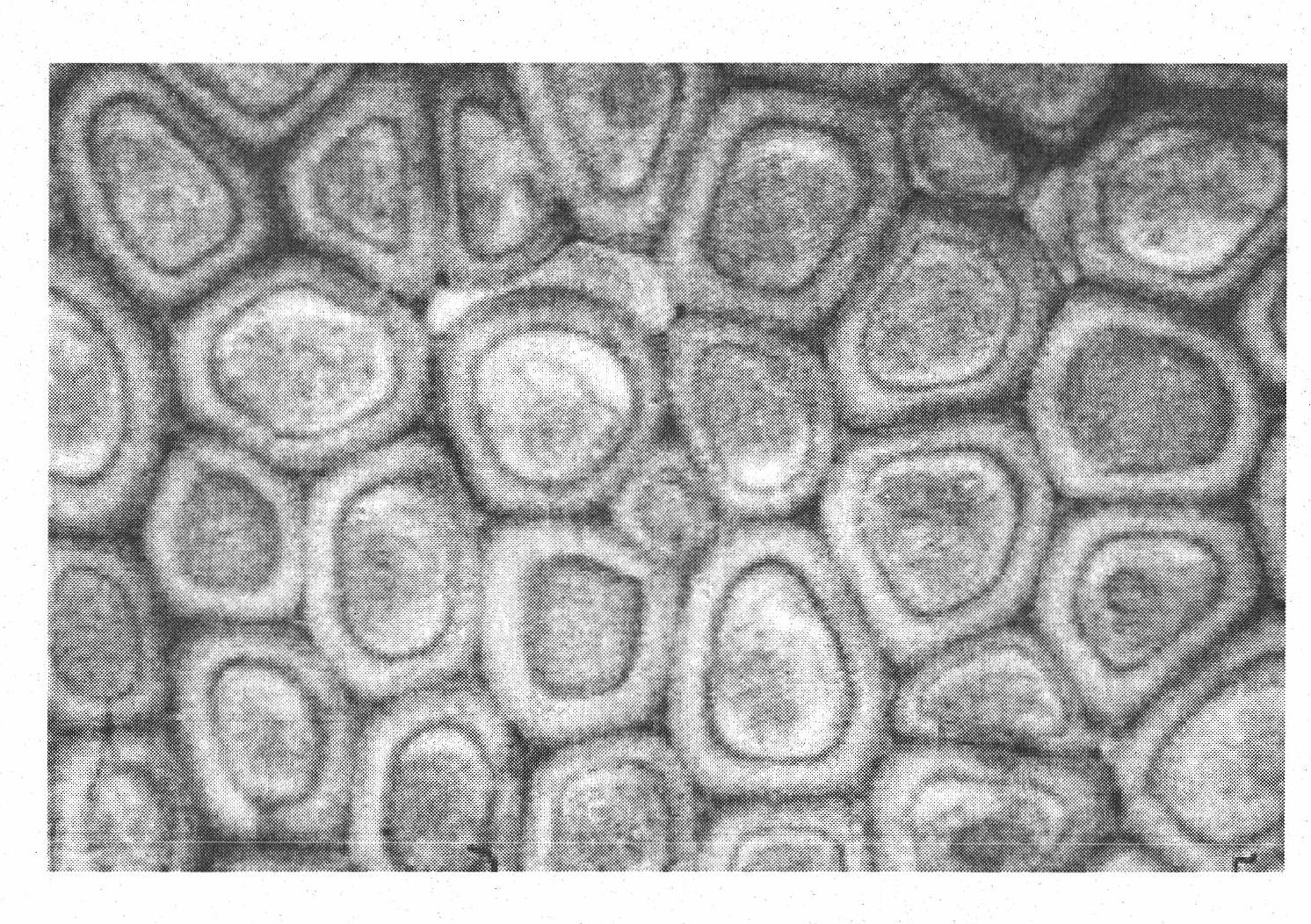

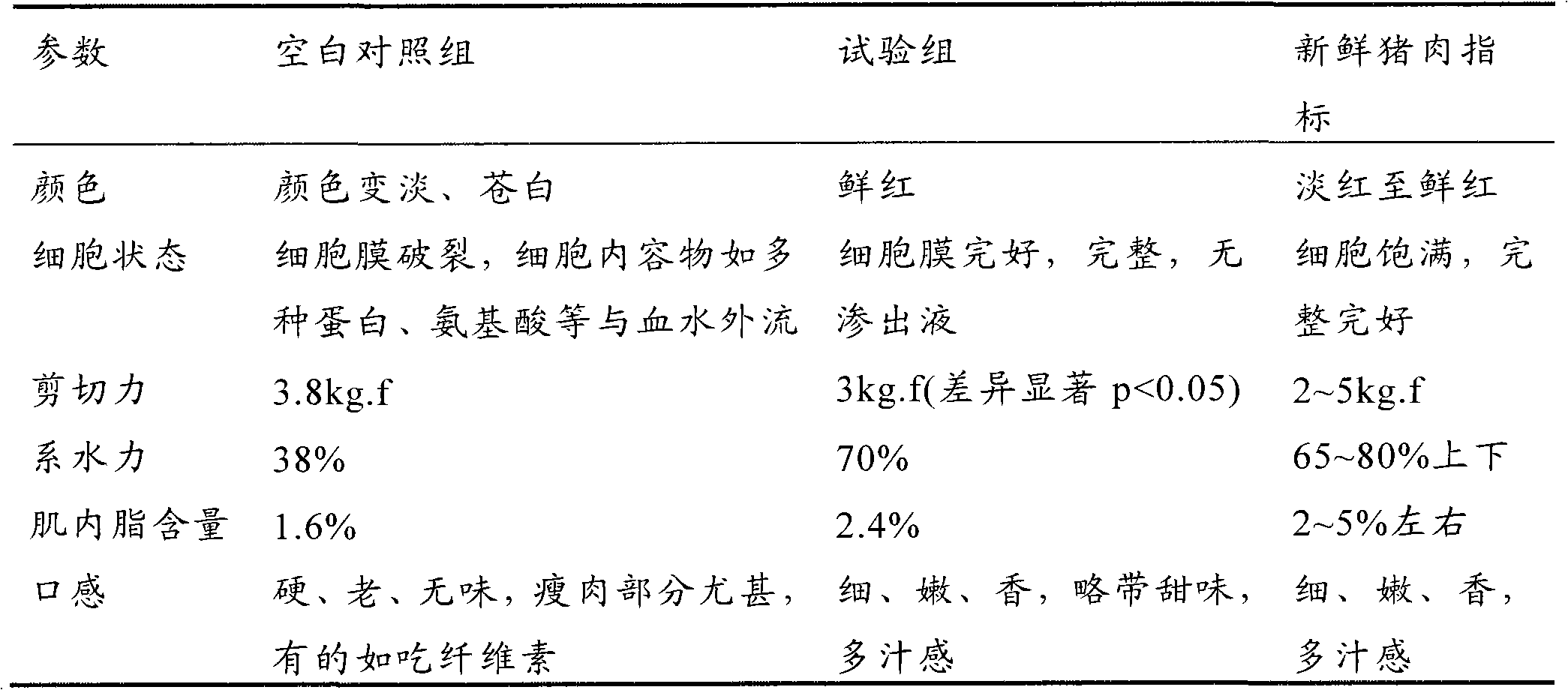

[0013] Cut 35kg of freshly slaughtered pork into 350g white strips with a thickness of 2.5cm as the test group. The core temperature reached room temperature and placed in 1.2 tons of micro-freezing liquid (-30°C, equivalent to air temperature-50°C) (purchase In the WJZ-A200 type micro-freezer from Shanghai Jiasheng Biological Products Co., Ltd., freeze quickly for 12 minutes. After freezing, the core temperature of the pork reaches -18℃, then it is soaked in ice water, drained, and then placed at -18℃ Store in the cold storage for 180 days, then remove and thaw. At the same time, white strips of the same number, size and shape just after slaughter were not frozen in micro-freezing liquid as a blank control group, and they were directly placed in a -18°C freezer and frozen and stored by cooling air conduction for 180 days before being taken out and thawed. Observe the color of the pork with naked eyes, observe the cell status under a microscope, and use conventional methods to ...

Embodiment 2

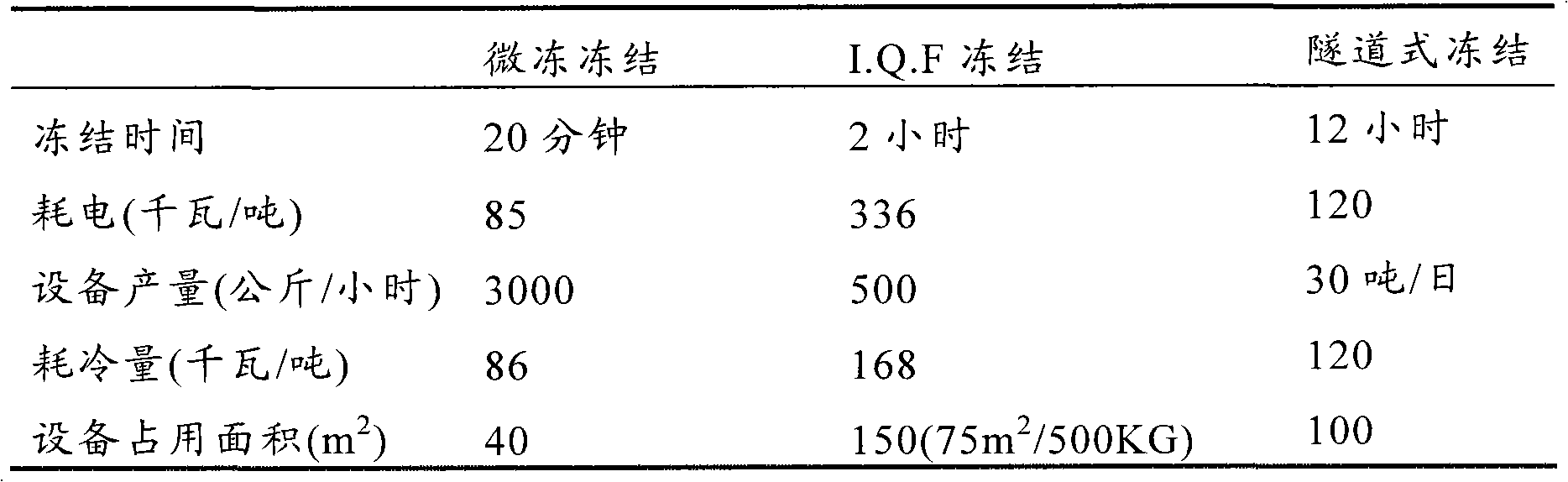

[0018] In the meat processing HACCP workshop, the freezing of pork with micro-freezing liquid is compared with the prior art IQF freezing, tunnel freezing and subsequent freezing of fresh pork to compare freezing time, power, output, labor, etc., as shown in Table 2. .

[0019] Table 2 Comparison of micro-freezing liquid freezing and I.Q.F freezing and tunnel freezing

[0020]

[0021]

[0022] Conclusion: The pretreatment method for freezing pork with micro-freezing liquid of the present invention can shorten the freezing time, save energy by 40%, reduce labor, and increase 3 times the daily production volume of conventional freezing.

Embodiment 3

[0024] Cut 35kg of freshly slaughtered pork into white strips of 350g each with a thickness of 2.5cm, with the core temperature reaching room temperature, and place it in WJZ- containing 1.2 tons of -35℃ micro-freezing liquid (purchased from Shanghai Jiasheng Biological Products Co., Ltd.) In the A200 micro-freezer, quickly freeze for 10 minutes. After freezing, the core temperature of the pork reaches -20°C, then it is soaked in ice water, drained, and stored in a -20°C freezer for 180 days, and then taken out and thawed for consumption.

[0025] Conclusion: The pork after being slightly frozen and thawed in micro-freezing liquid is bright red and looks like it was just slaughtered; the taste is delicious, the color and fragrance are complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com