Double plate type motor-driven wall dust-absorption polisher

A double-disc, grinding machine technology, applied in machine tools, grinding machines, grinding/polishing equipment suitable for grinding workpiece planes, etc., to achieve the effect of excellent dust removal structure and stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, so that the public can better grasp the specific implementation means of the present invention and fully understand the advantages and effects of the present invention.

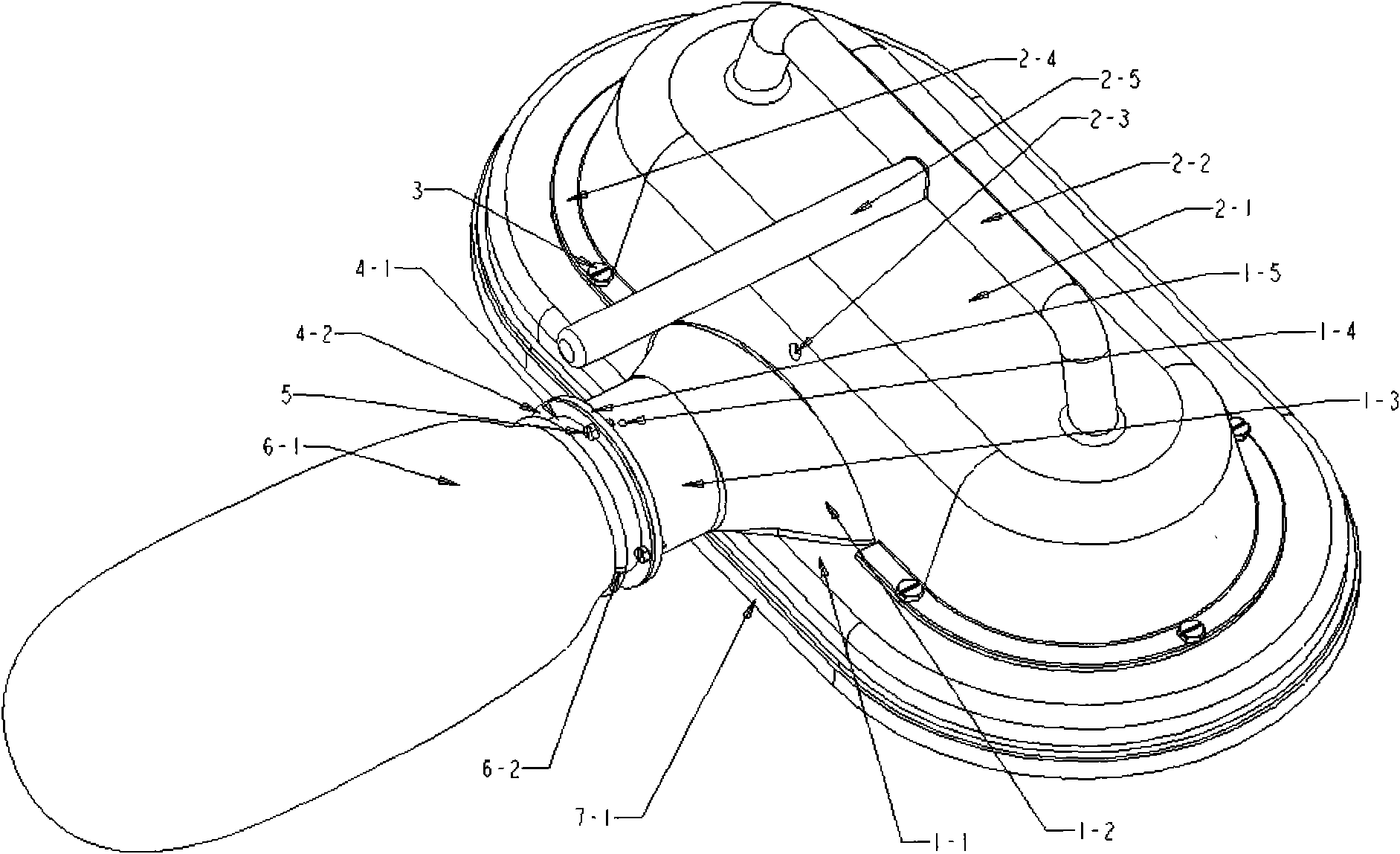

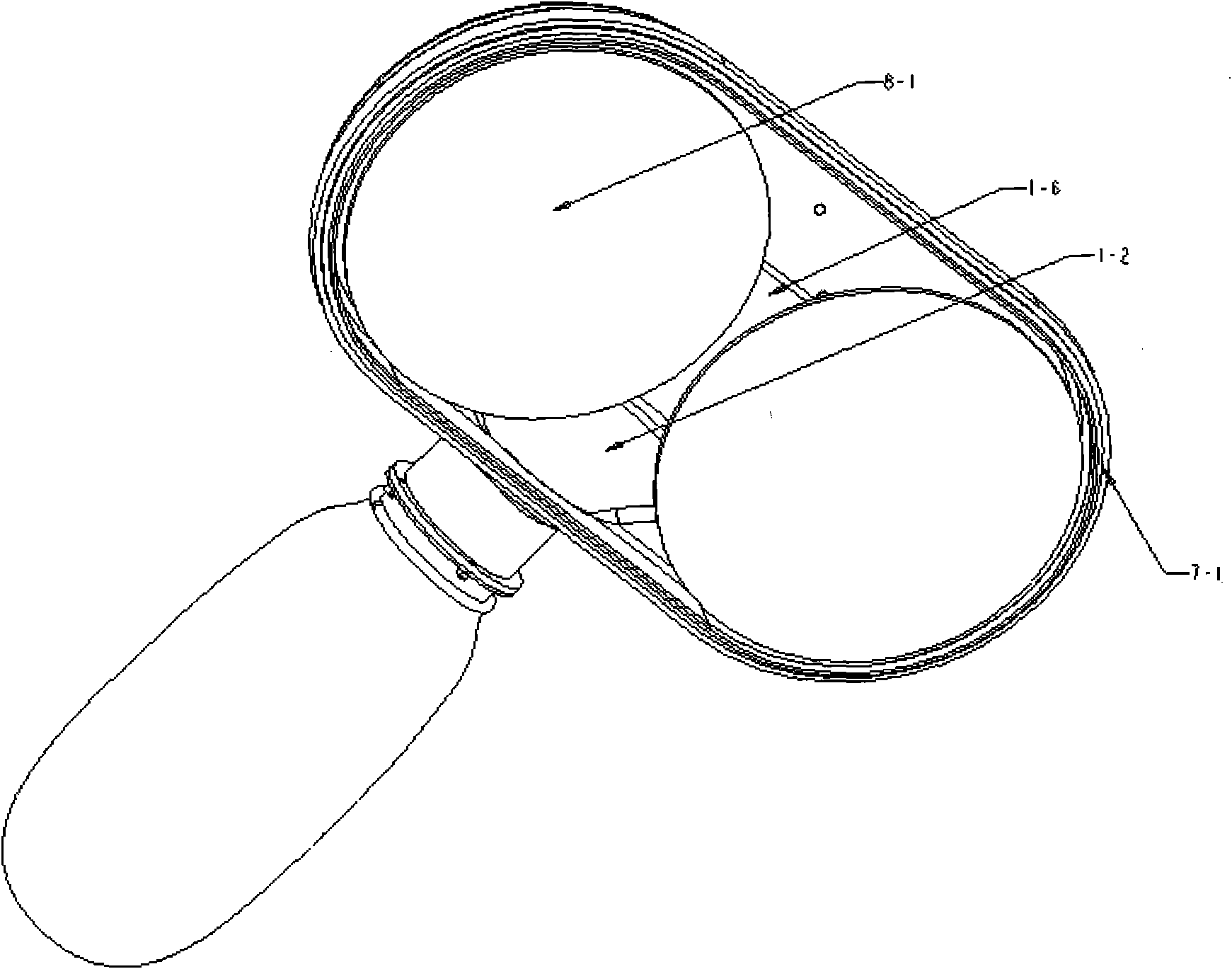

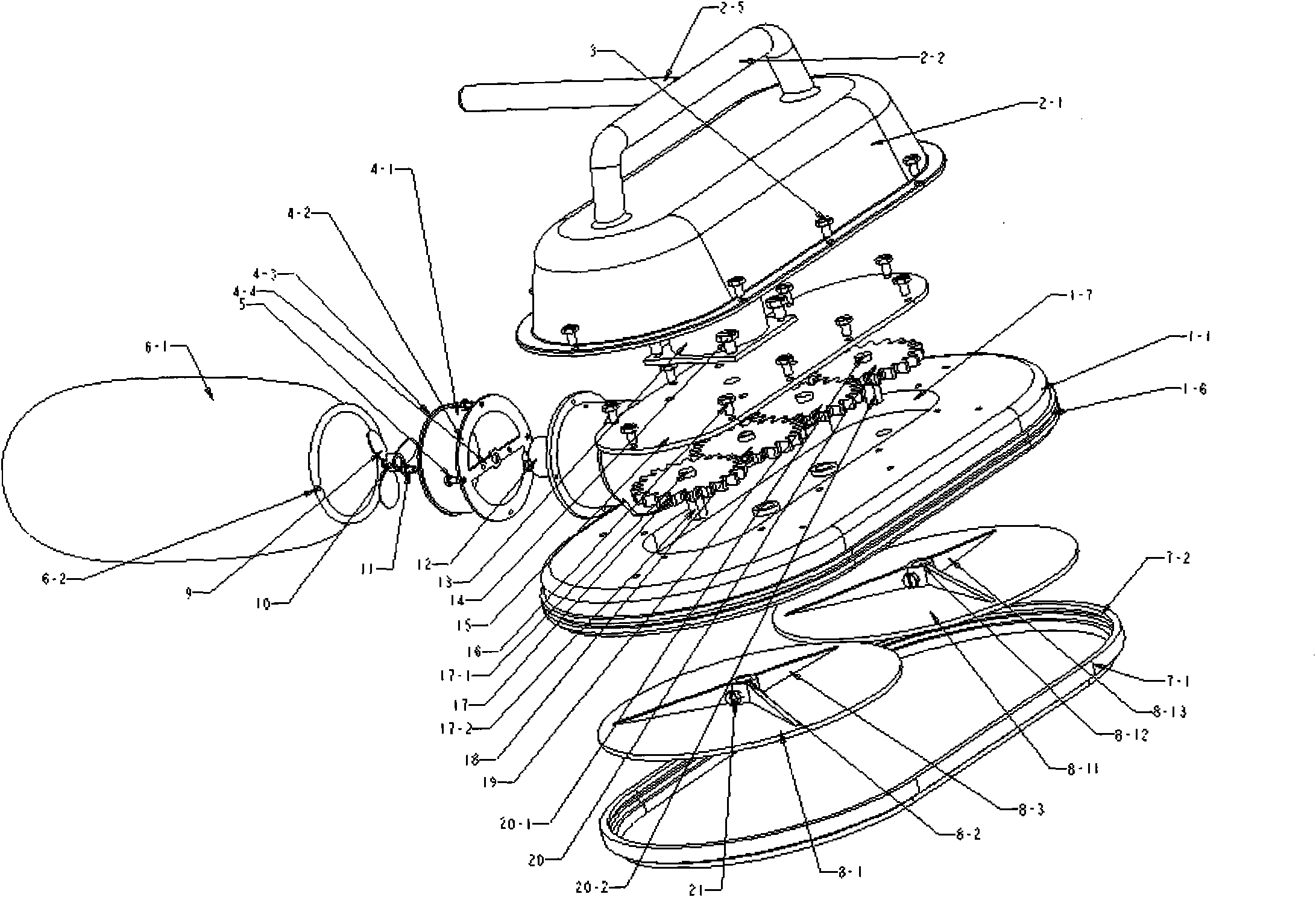

[0012] see figure 1 1. The casing 1-1 is connected with the dust suction pipe 1-3 as a whole, and the dust suction pipe 1-3 is provided with an outlet hole 1-4 for wiring; the rear cover 2-1 is provided with a rear cover flange 2-4 , installed on the casing 1-1 through screws 3, a handle 2-2 is provided on the back cover 2-1 to facilitate the grinding operation, and the outlet 2-3 is used for wiring; the dust suction device on the dust suction device 4-1 is protruding The edge 4-2 and the suction pipe flange 1-5 are connected by screws 5; the bag opening of the dust bag 6-1 is provided with a rope threading hole 6-2 to pass through it with a rope, and is tied to the suction pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com