Heat recovery system for vehicle

A heat recovery, heat absorption technology, used in vehicle components, heating/cooling equipment, electromechanical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

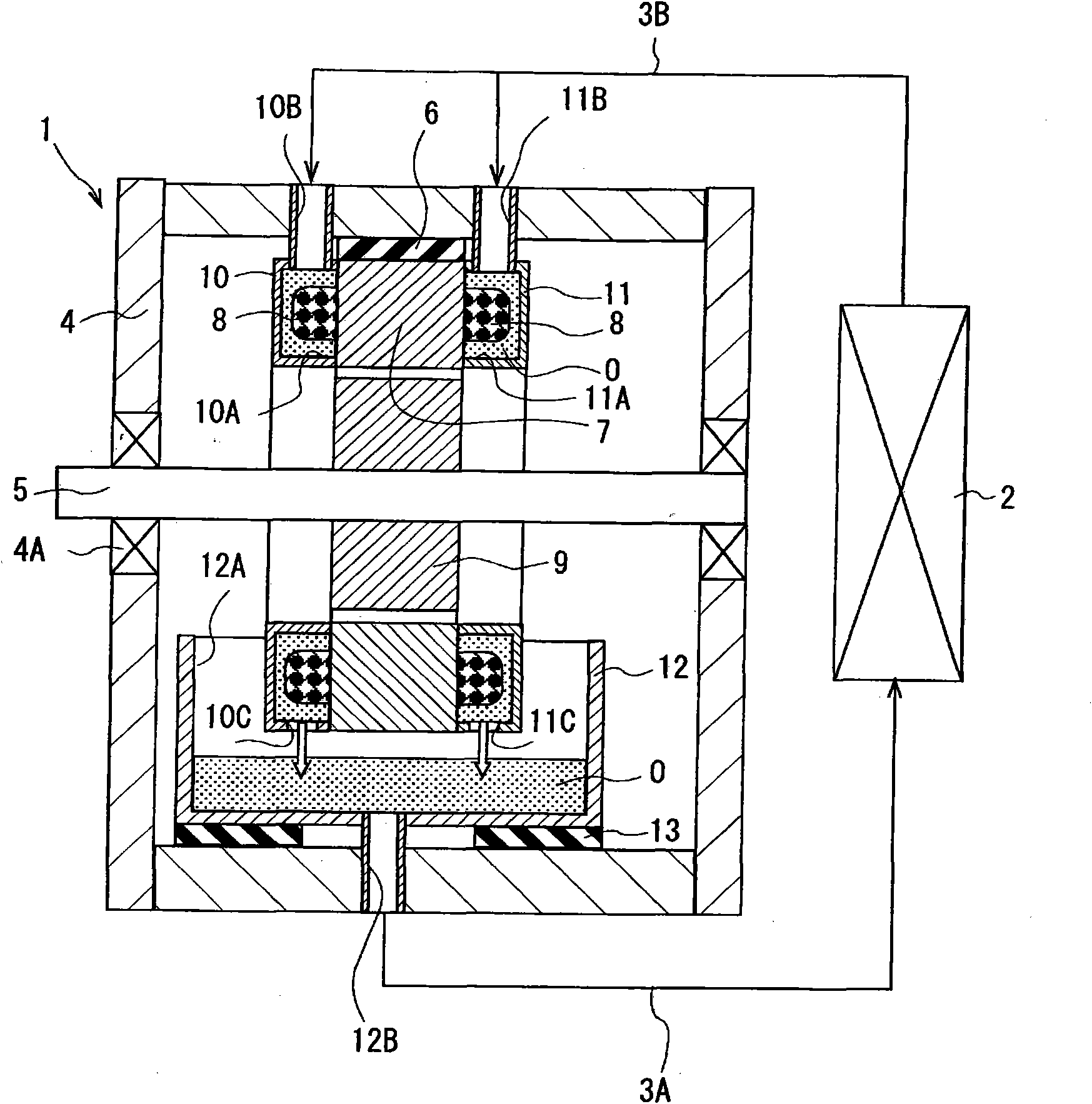

[0026] refer to Figure 1 to Figure 4 , the heat recovery system according to the first embodiment of the present invention for a vehicle will be described below.

[0027] refer to figure 1 , the heat recovery system includes a motor 1 as an electric rotating device, a heat exchanger 2 and pipes 3A, 3B. The pipes 3A, 3B connect the motor 1 to the heat exchanger 2 and enable oil O as a first heat exchange medium to flow between the motor 1 and the heat exchanger 2 .

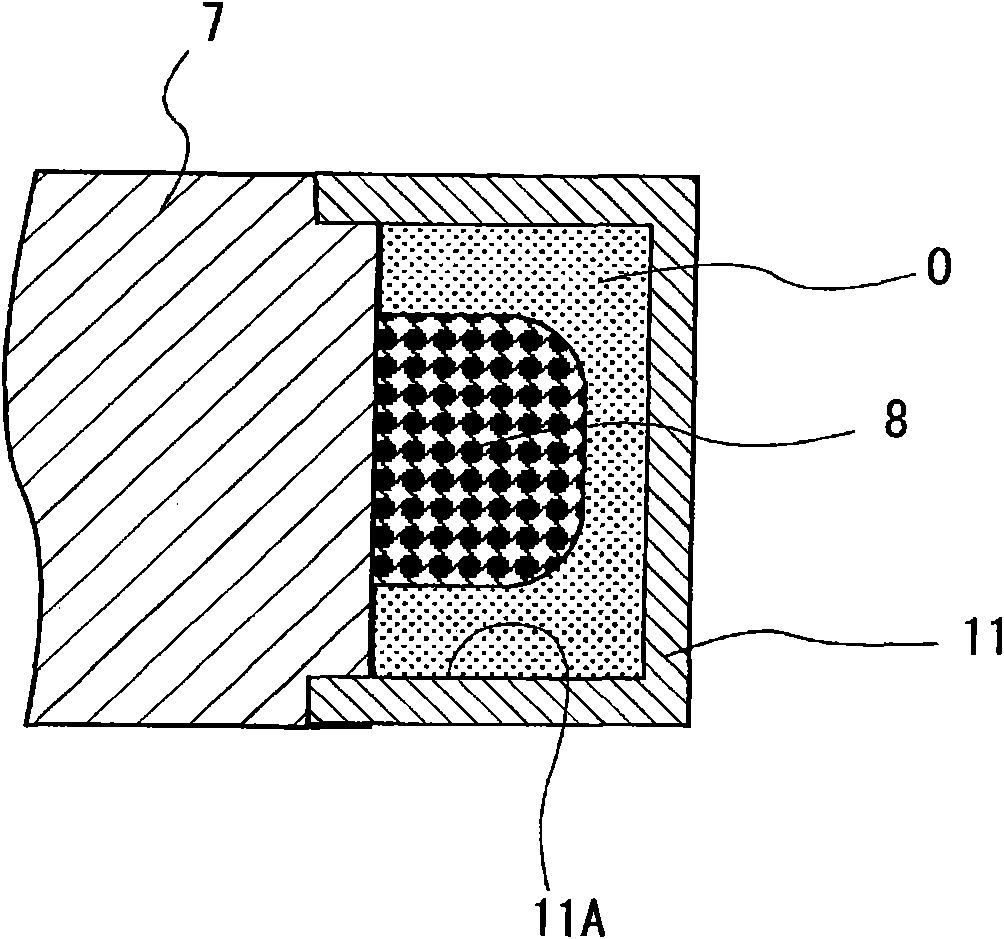

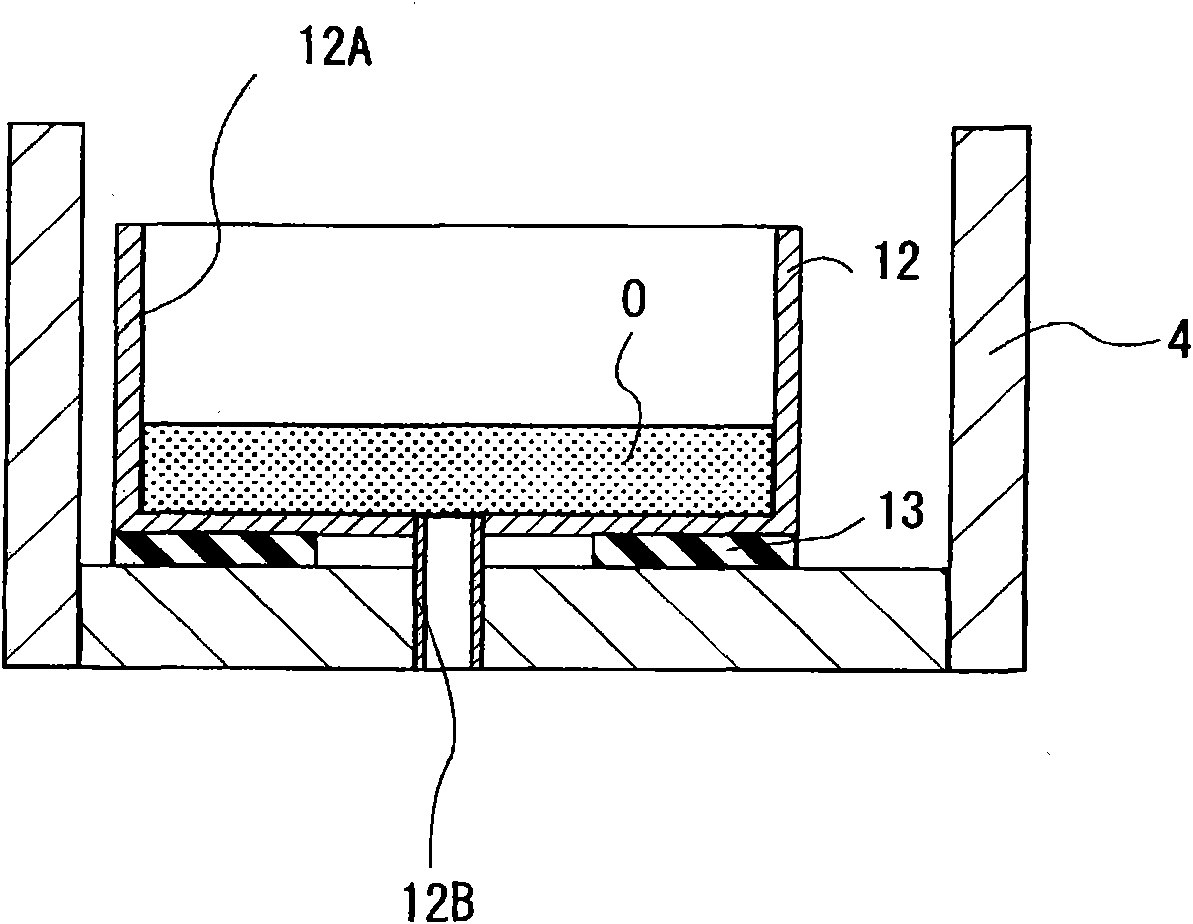

[0028] The motor 1 has a housing 4 and a rotary shaft 5 rotatably supported by the housing 4 via a bearing 4A. The stator core 7 is fixed to the inner periphery of the case 4 via the heat insulator 6 as an auxiliary heat insulator portion. Rubber is used as a material for the heat insulator 6 . The stator core 7 has a plurality of slots equiangularly spaced and extending in the axial direction of the stator core 7 , and the coils 8 are wound in these slots of the stator core 7 . Inside the stator core 7 , a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com