Method for stopping horizontal oscillation in large-scale steel open caisson construction

A horizontal swing and construction technology, which is applied in caissons, infrastructure engineering, construction, etc., can solve the problems of anchor rope breakage, little effect of suppressing swing, and large hull loss, etc., and achieves easy operation and adjustment, and large-scale promotion Value, the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

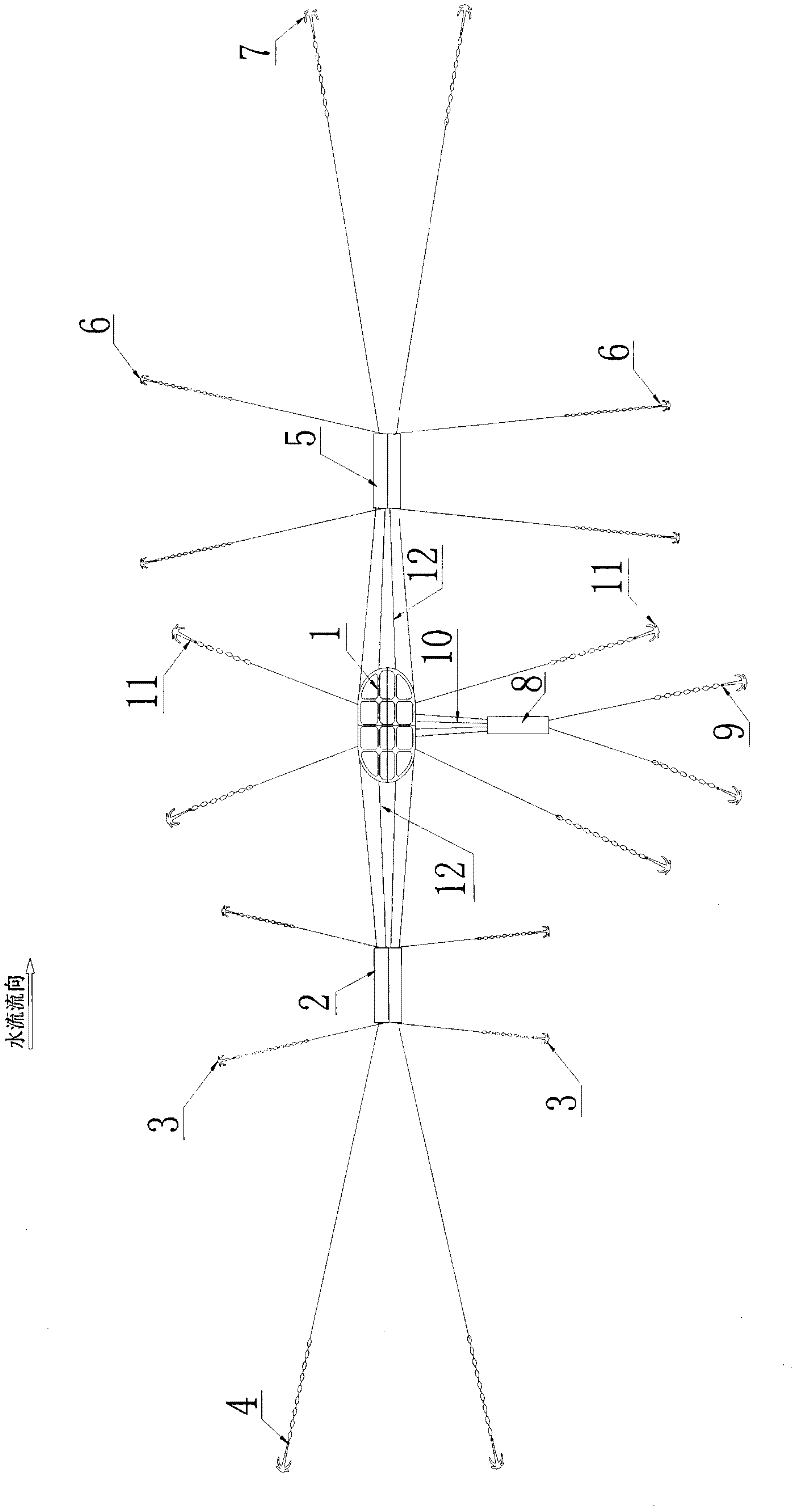

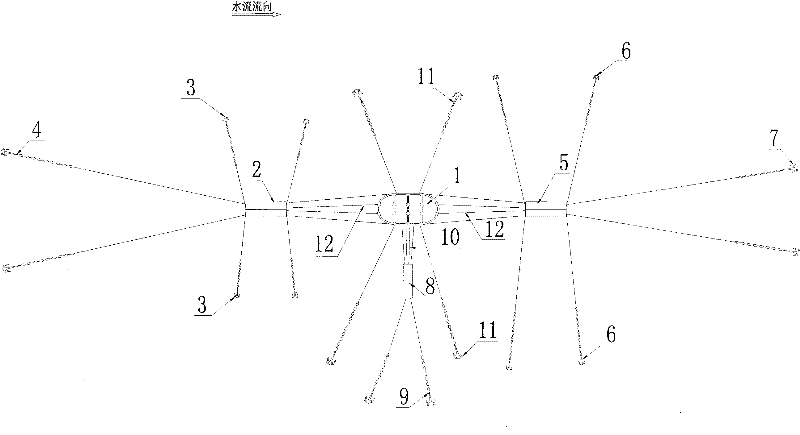

[0018] Such as figure 1 As shown, the steel caisson 1 is connected to the front positioning ship 2 and the rear positioning ship 5 through the stay cable 12, and resists the force in the horizontal and vertical directions of the caisson through the joint action of the main anchor 4, the tail anchor 7, and the side anchor 11 of the steel caisson. , to realize the preliminary positioning of the caisson. The positioning of the front positioning ship 2 is realized by the joint action of the front positioning ship side anchor 3 and the main anchor 4, and the positioning of the rear positioning ship 5 is realized by the joint action of the rear positioning ship side anchor 6 and the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com