Protective device for high-voltage power equipment

A technology for high-voltage power equipment and fuse devices, applied in circuits, electrical switches, electrical components, etc., can solve the problems of burning transformers, fuses that cannot be used for power equipment, and accident expansion, so as to eliminate potential safety hazards and fill the field of overcurrent insurance. blank, realize the effect of overcurrent protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

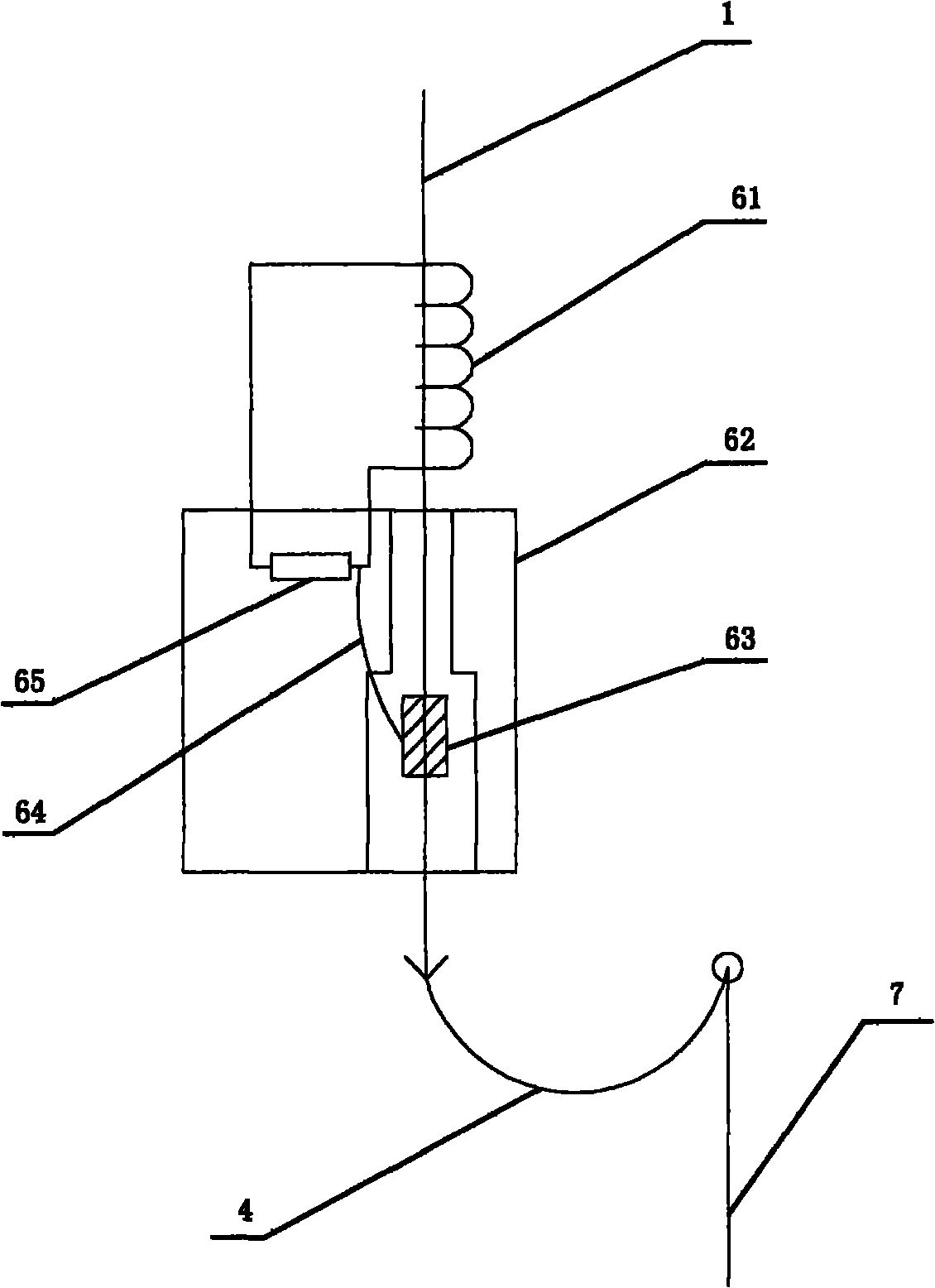

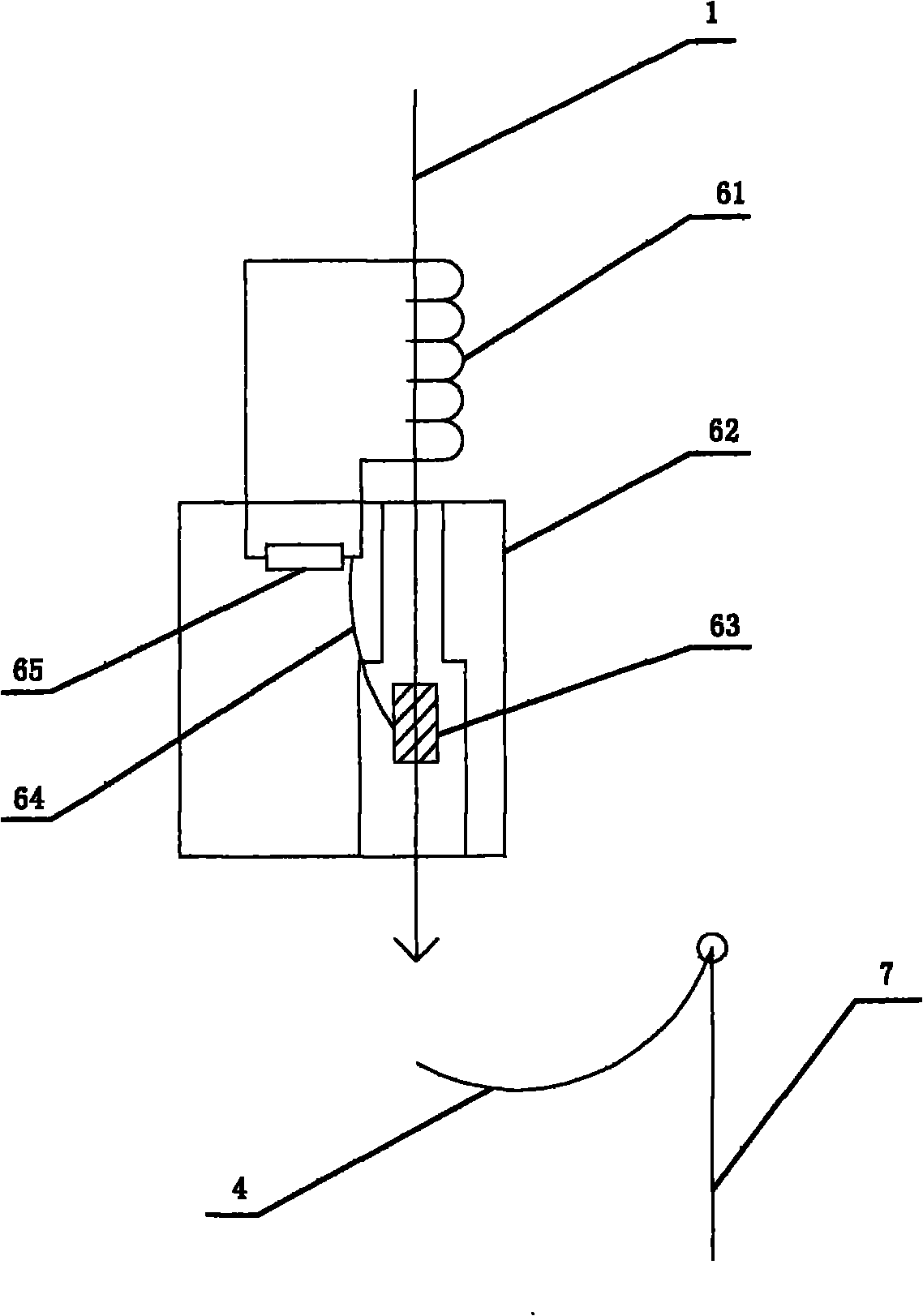

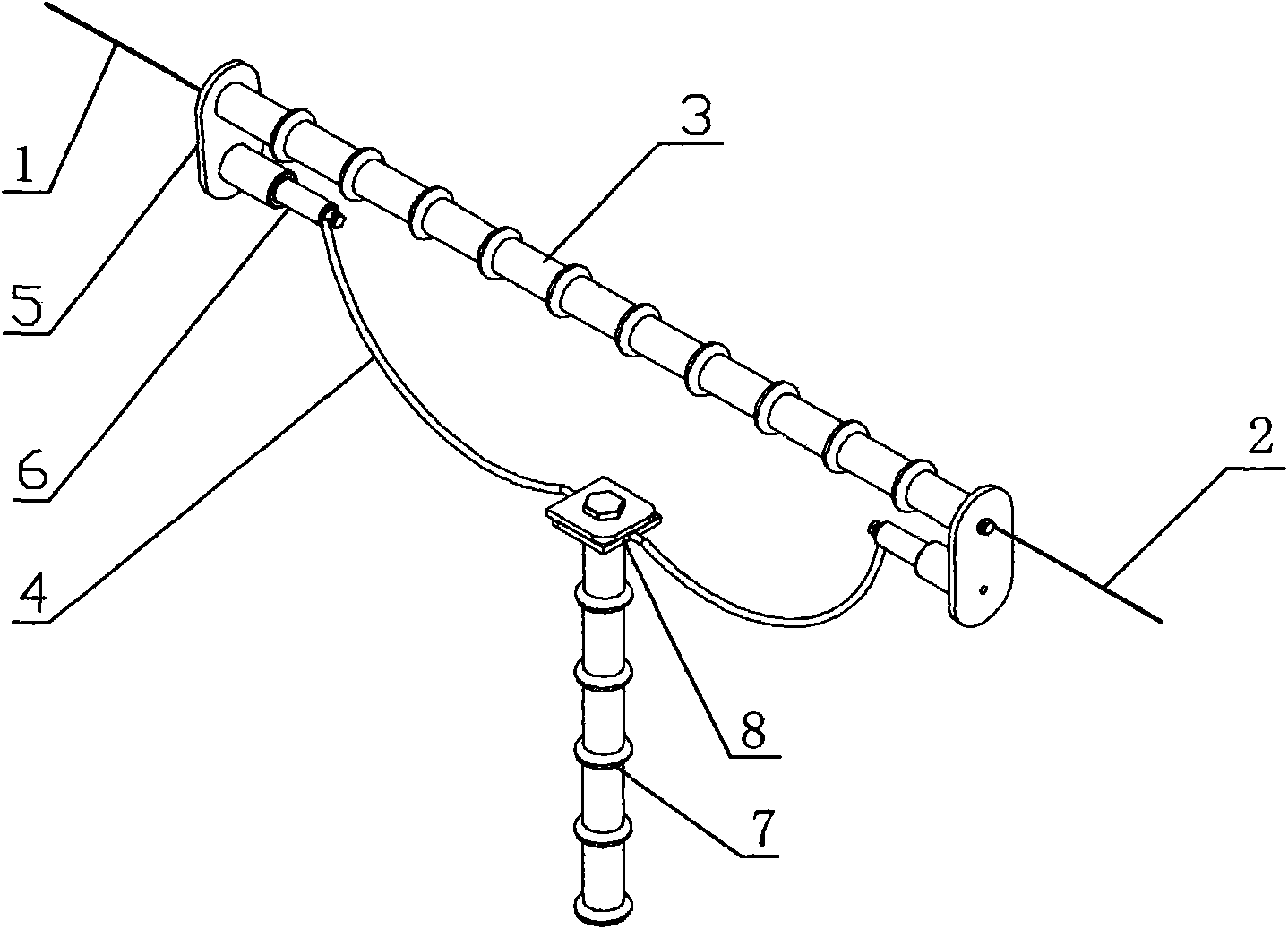

[0015] refer to figure 1 , figure 2 , a high-voltage power equipment safety device, including an insulating isolation bar 3 arranged between the left and right power supply busbars 1 and 2, a metal lead 4 is connected between the two ends of the insulating isolation bar 3, and the two ends of the insulating isolation bar At least one end of the part is provided with a disconnector 6 that can bounce off the metal lead wire under a fault current. One end of the disconnector 6 is connected to the insulating isolation bar 3 through the fixing device 5, and the other end is connected to the metal lead wire 4. The metal lead wire 4 The bottom is fixedly connected with an insulating support rod 7 to prevent the metal lead from bouncing off and grounding.

[0016] In order to ensure the safety of the electrical equipment, disconnectors 6 are provided at both ends of the isolating rod 3, so that even if the disconnector on one side breaks down, the disconnector on the other side can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com