Method for connecting plant pillar and crane girder

A connection method and crane beam technology, which are applied in the directions of construction and building structure, to achieve the effects of simple construction, less material consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

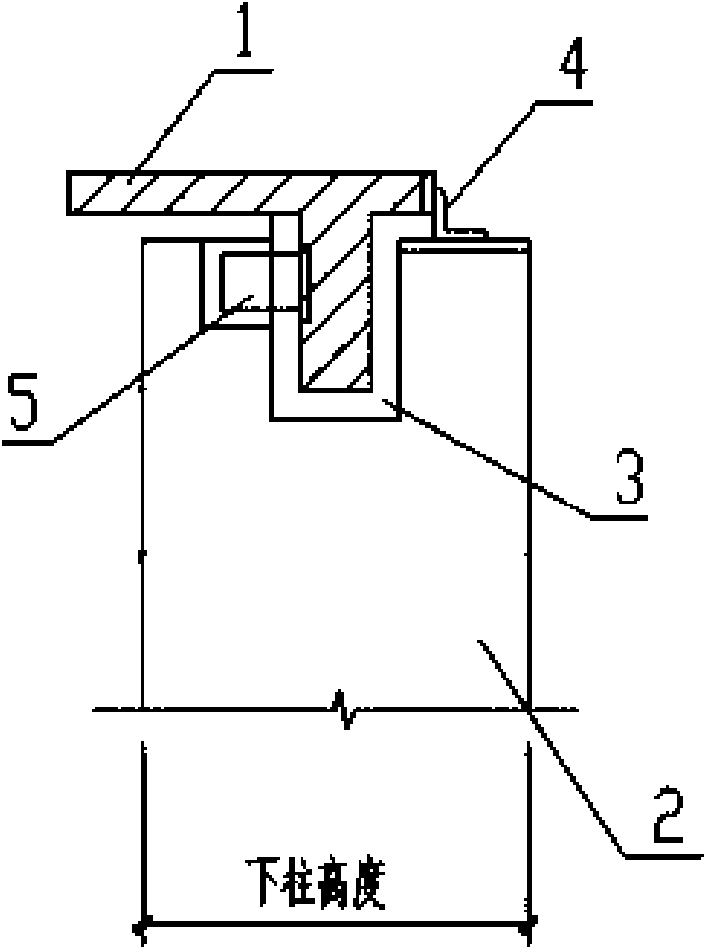

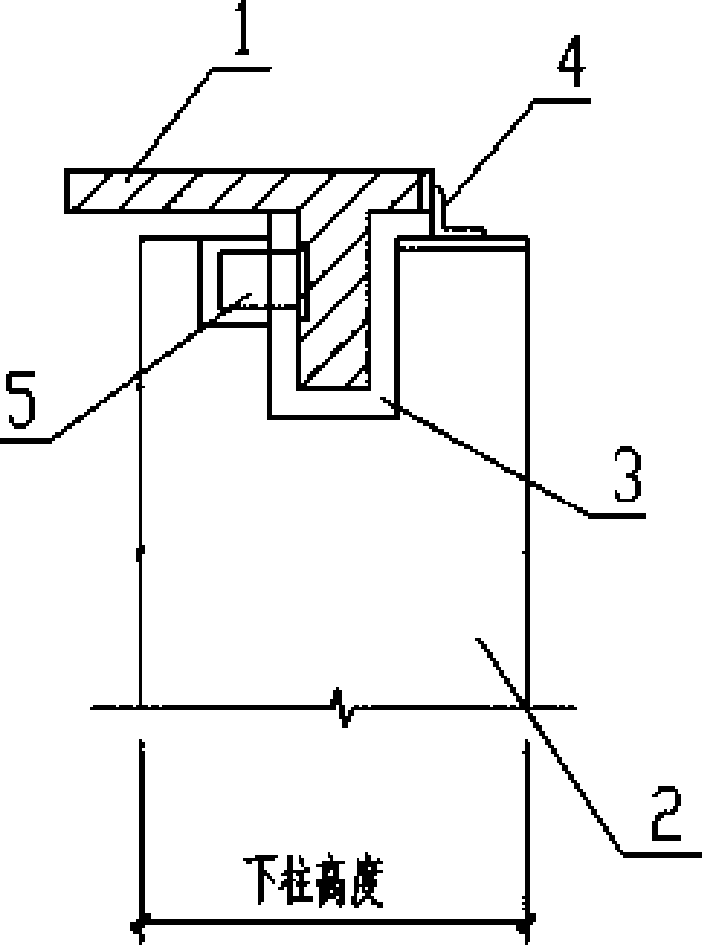

[0008] Embodiment 1: the connection method of the workshop column and the crane beam, such as figure 2 As shown, including the crane beam 1 and the workshop column 2. Make a slot hole in the middle of the top of the workshop column 2, place the crane beam 1 in the slot hole and fill it with concrete 3.

[0009] Wherein, the crane beam 1 needs to be welded with the crane beam 1 with the angle steel 4 and the flat steel 5 to ensure its lateral and longitudinal stability.

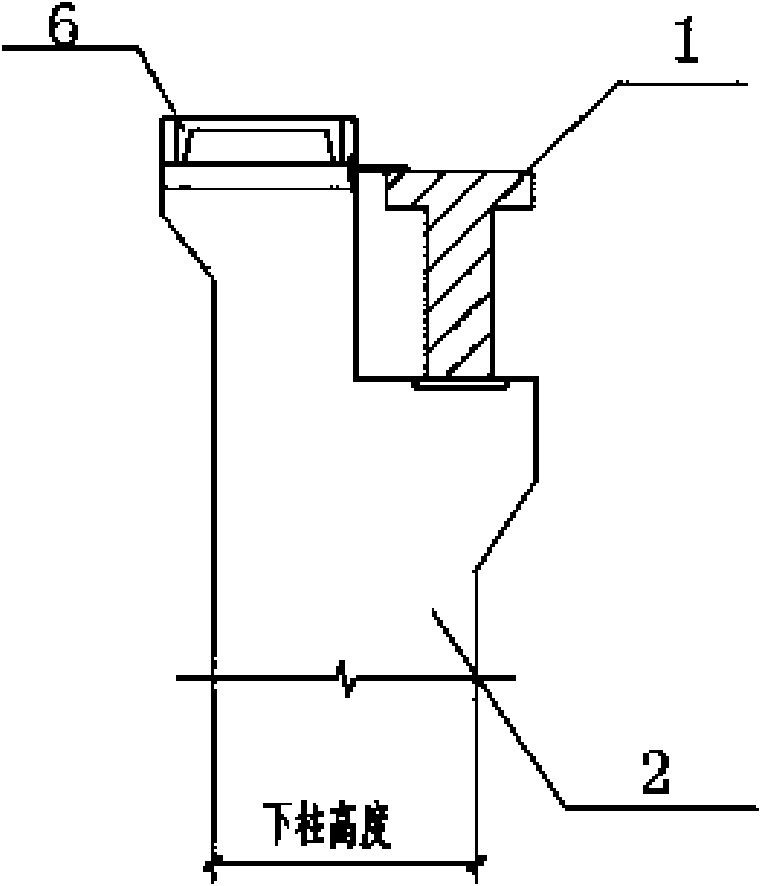

[0010] The crane girder protruding from the flange can be used as a combined structure of the crane girder 1 and the walkway plate 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com