Spraying type environmentally-friendly electronic powder painting mechanism

An electronic powder, environmentally friendly technology, applied in the manufacture of circuits, electrical components, electrode systems, etc., can solve the problems affecting the uniformity of electronic powder, the decline of product stability, and increase the cost of production enterprises, so as to save cooling and heat preservation costs. , Low operating cost, and the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

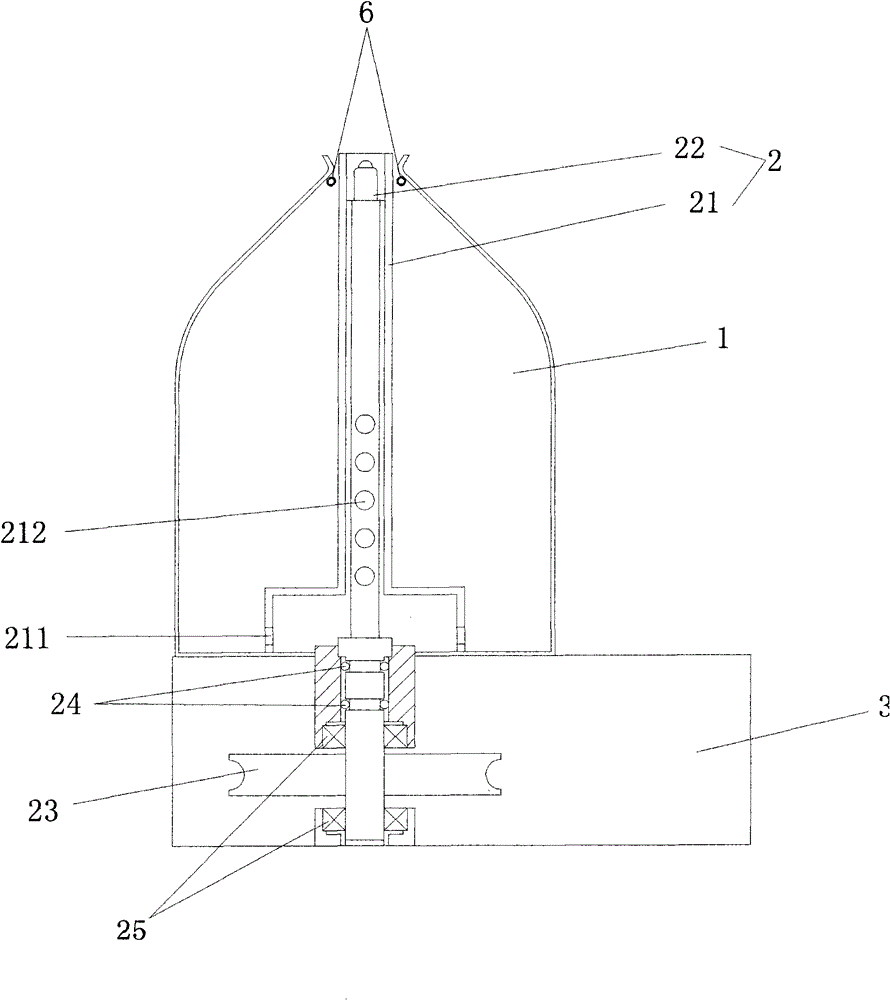

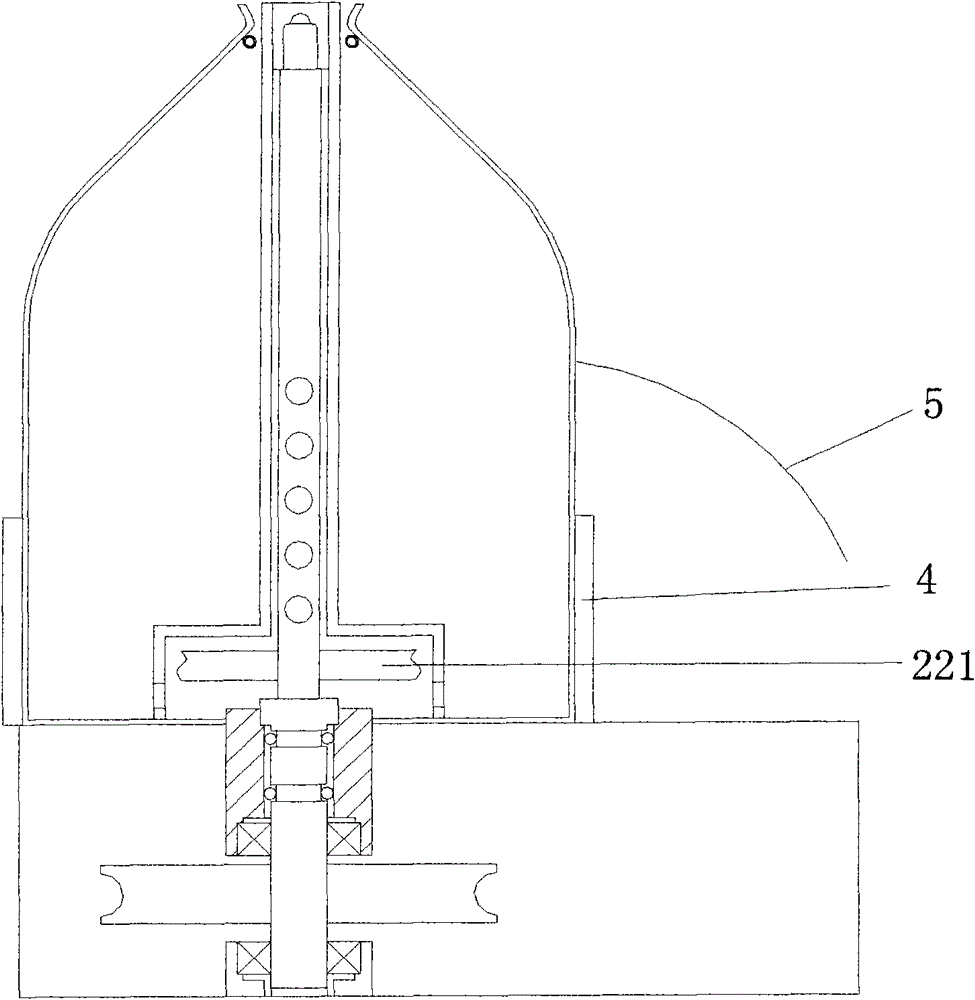

[0034] Such as figure 1 Shown is a suction spray type environmental protection type electronic powder mechanism, which includes a container 1, a suction spray device 2 and a base 3 for placing the container 1, and the suction spray device 2 includes a feeding part and a driving part; the feeding part passes through Some bearings 25 are rotatably fixed on the base 3 and stretch into the container 1; the drive unit is located in the base 3, and it includes: a transmission wheel 23, a motor driving the transmission wheel 23; Airtightness, the feeding part is provided with a sealing ring 24 from the position of the transmission wheel 23 and the connection between the container 1 and the base 3 .

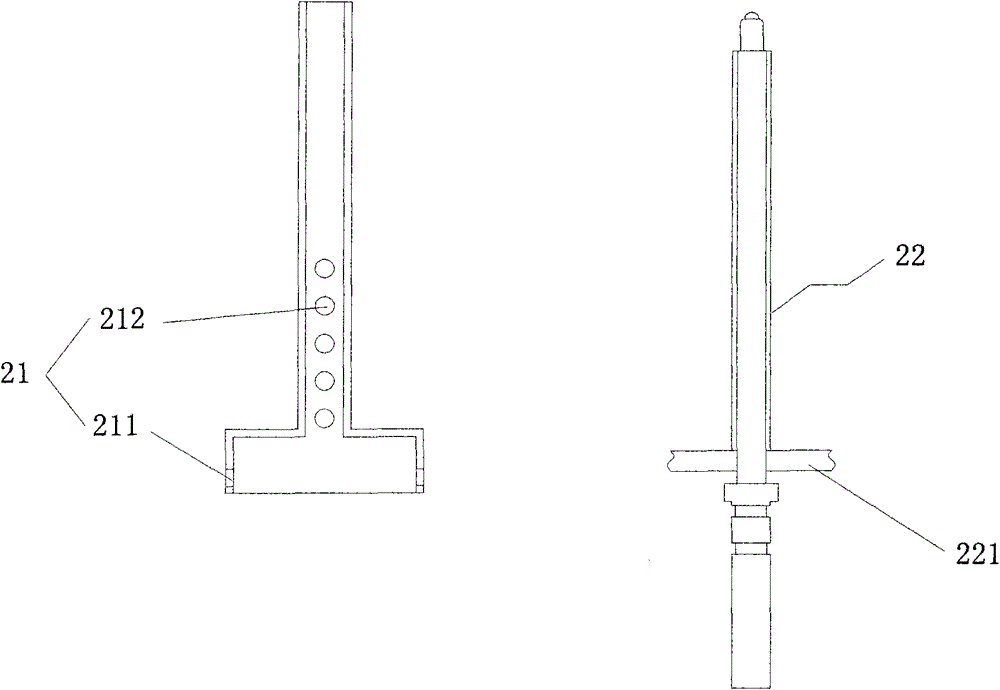

[0035] Such as figure 2 As shown: the feeding part includes: an inverted T-shaped pipe 21 and a feeding pipe 22; the horizontal part of the inverted T-shaped pipe 21 is provided with an opening 211, and the middle part is provided with a suction and overflow hole 212 (hereinafter refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com