Dry type iron core reactor capable of realizing parallel capacitor grouping

A technology of reactors and capacitors, which is applied in transformers/inductor coils/windings/connections, inductance with magnetic cores, reactive power compensation, etc. Overpayment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

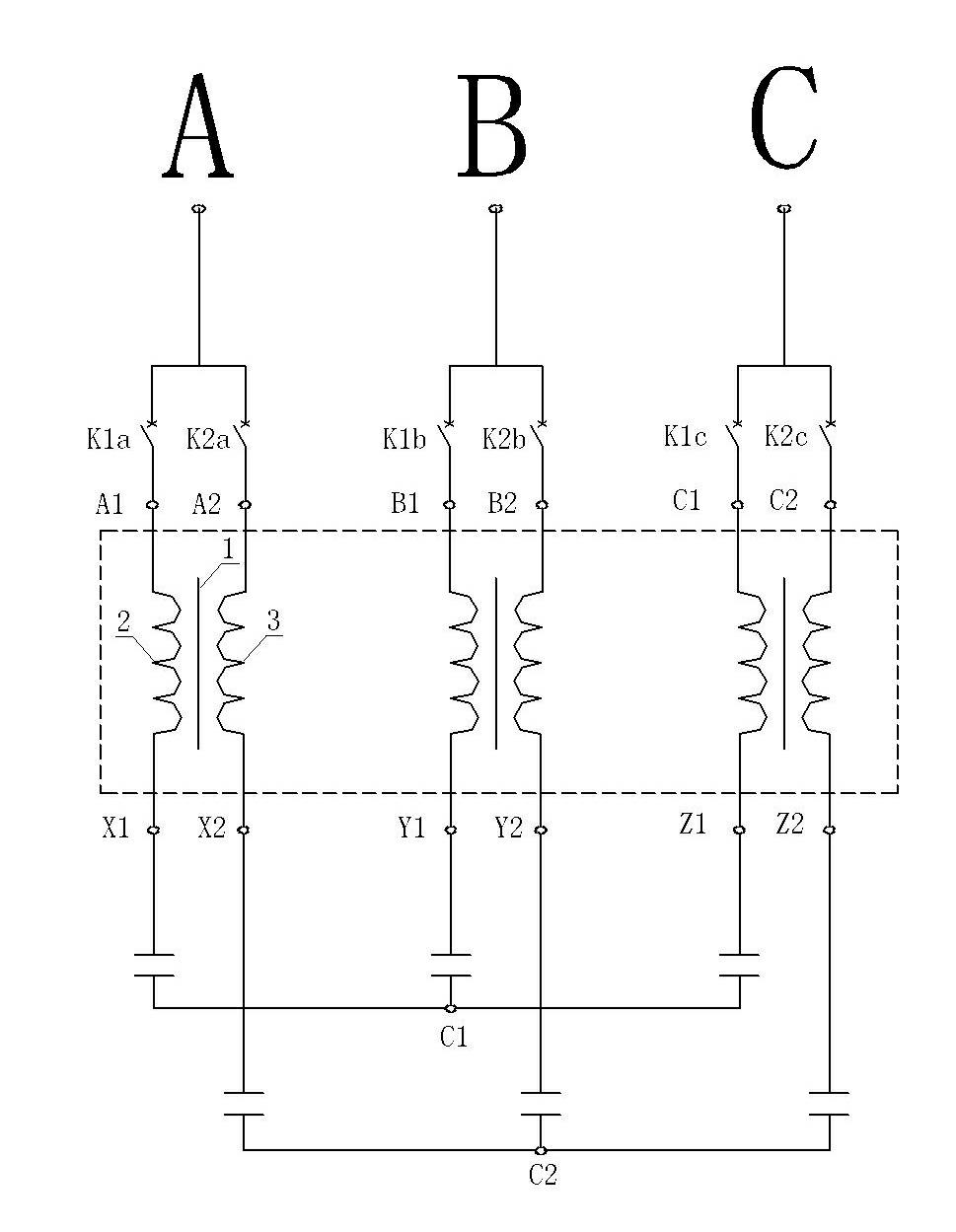

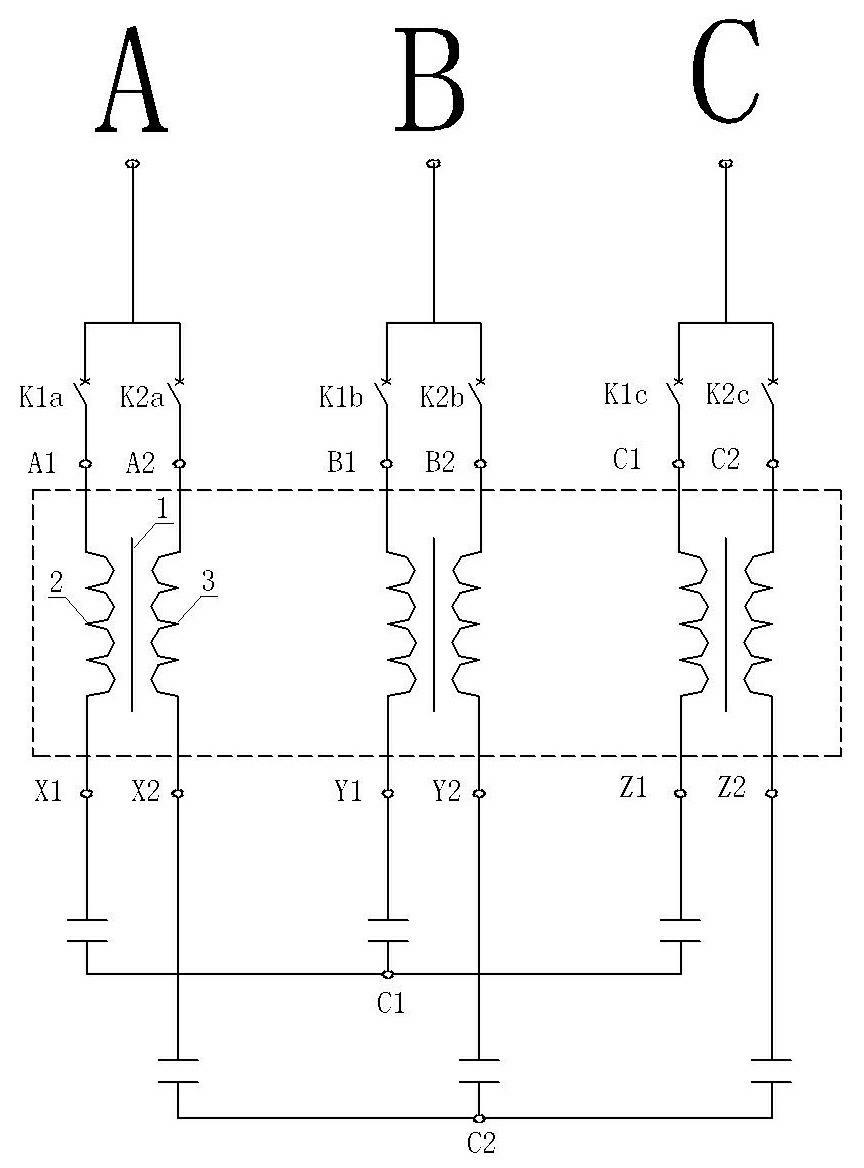

[0007] As shown in the figure, the reactor includes a reactor core 1. Two sets of coils 2 and 3 are respectively wound on the reactor core 1 of each phase, and the two sets of coils 2 and 3 are wound side by side on the same side. There are three sets of incoming line terminals A1 and A2, B1 and B2, C1 and C2, and three sets of outgoing line terminals X1 and X2, Y1 and Y2, Z1 and Z2.

[0008] When wiring, connect the three sets of incoming line terminals A1 and A2, B1 and B2, C1 and C2 to the phase A, phase B and phase C of the three-phase electricity respectively through vacuum switches K1a and K2a, K1a and K2a, K1a and K2a, and connect the three Group outlet terminals X1 and X2, Y1 and Y2, Z1 and Z2 are respectively connected to two capacitor banks C1 and C2, so that each group of coils is connected in series in the corresponding capacitor bank circuit, among which vacuum switches K1a, K1b, and K1c form a group , Vacuum switches K2a, K2b, K2c are a group. Each group of coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com