Frame for a device for producing a three-dimensional object, and device having such a frame for producing a three-dimensional object

A technology for three-dimensional objects and frames, which is applied in the field of frames for devices, and can solve problems such as frame heating and strong thermal loads on frames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

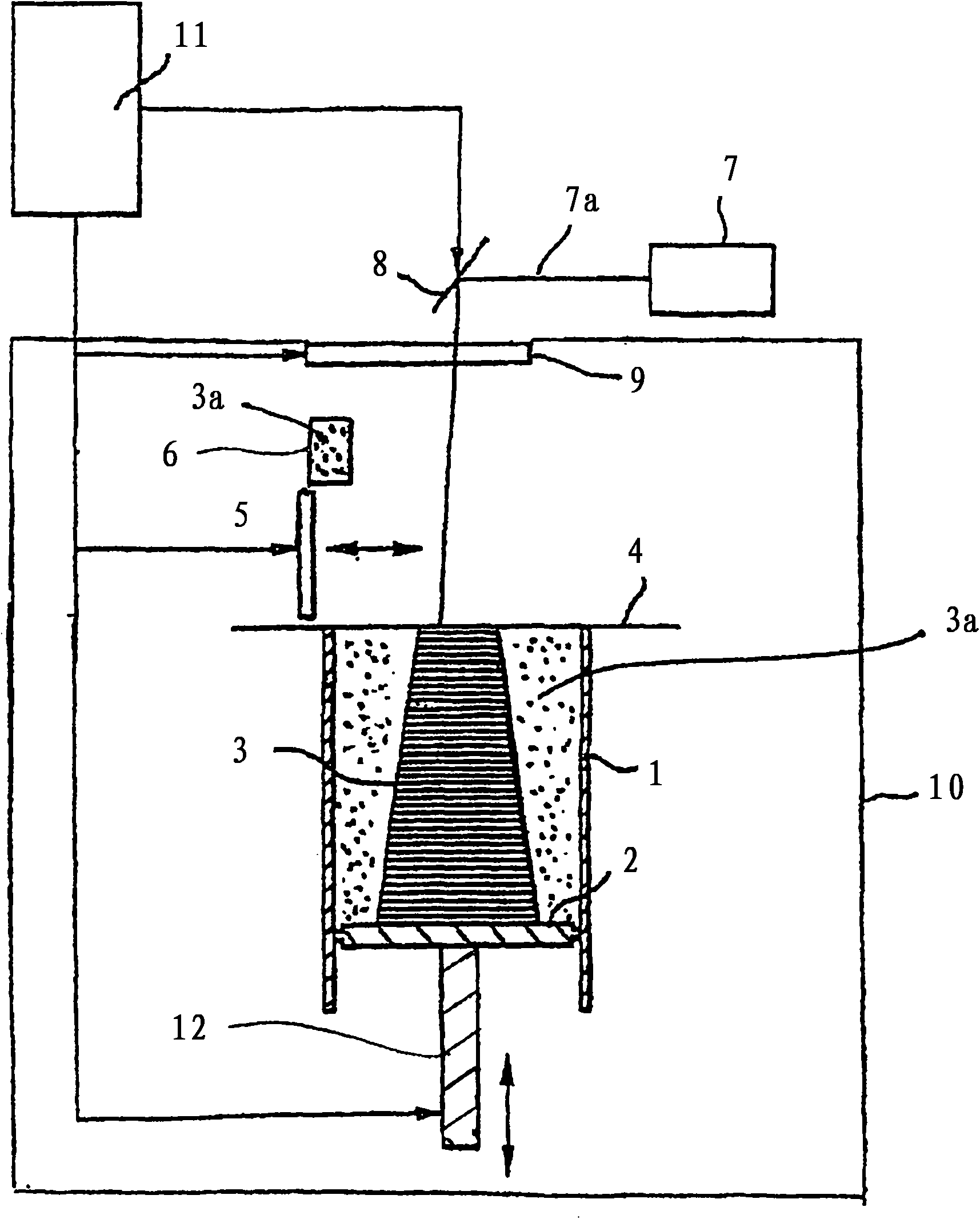

[0014] figure 1 A schematic diagram of a device according to the invention for producing a three-dimensional object 3 is shown, which is designed as a laser sintering device in the exemplary embodiment.

[0015] The laser sintering device has an upwardly open frame 1 and a vertically movable plate 2 within the frame, the plate carrying a three-dimensional object 3 to be manufactured. The frame 1 and the plate 2 internally define a manufacturing space. The plate 2 is connected to a lifting mechanism 12 which moves it in the vertical direction so that the layer to be consolidated of the current object 3 is in a working plane 4 . The frame 1 and the flat panel 2 are modularly connected to each other to form a replaceable rack. After the production of the three-dimensional object 3 has been completed, the exchangeable frame and the object 3 produced therein can be removed from the device and replaced by a new exchangeable frame.

[0016] Furthermore, an applicator 5 is provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com