Hydraulic shaft detaching device

An off-axis, hydraulic technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult disassembly, long operation cycle, and easily damaged equipment, so as to shorten the disassembly time, reduce labor intensity and economic benefits obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

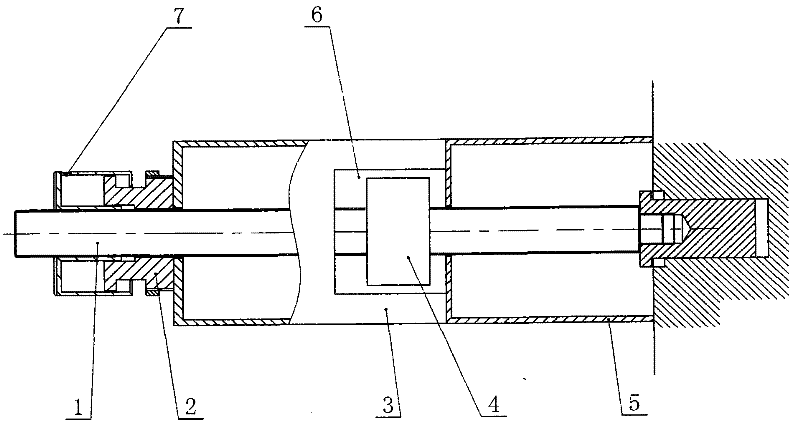

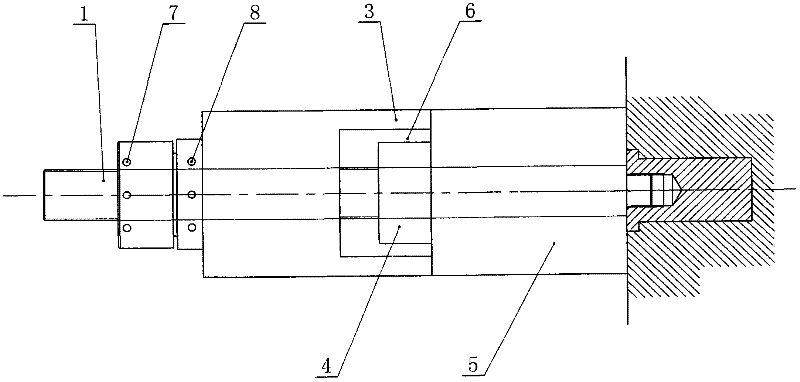

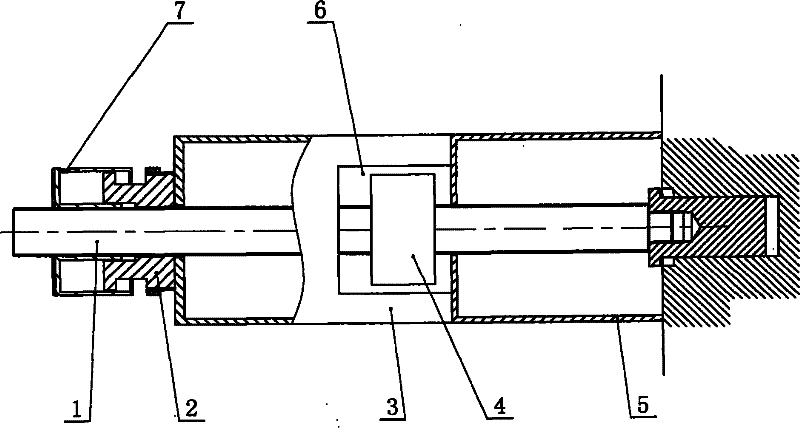

[0010] The invention as figure 1 , 2 As shown, a hydraulic shaft extractor includes a screw 1, which is characterized in that: the right part of the screw 1 is covered with a first-level sleeve 5, and the left side of the first-level sleeve 5 is designed with a lock nut 4, and the lock nut 4 and the screw 1 Threaded connection, the left side of the lock nut 4 is designed with a secondary sleeve 3, the secondary sleeve 3 is sleeved on the screw 1, and the secondary sleeve 3 has a working port 6, the working port 6 corresponds to the lock nut 4, the second The left side of the stage sleeve 3 is designed with a hydraulic nut 2 with an oil injection hole 7 and a dismounting hole 8, and the hydraulic nut 2 is threadedly connected with the screw rod.

[0011] In this embodiment, the lock nut 4 is a hydraulic nut.

[0012] When using the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com