Soft sealing butterfly valve and method for preparing valve seat sealing ring thereof

A kind of sealing ring, soft sealing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

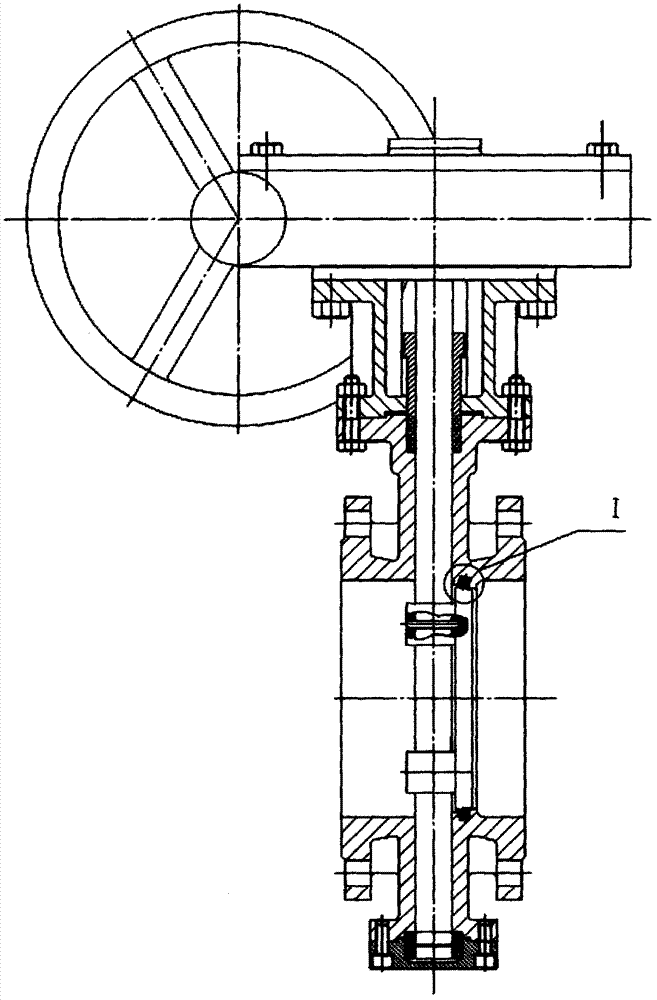

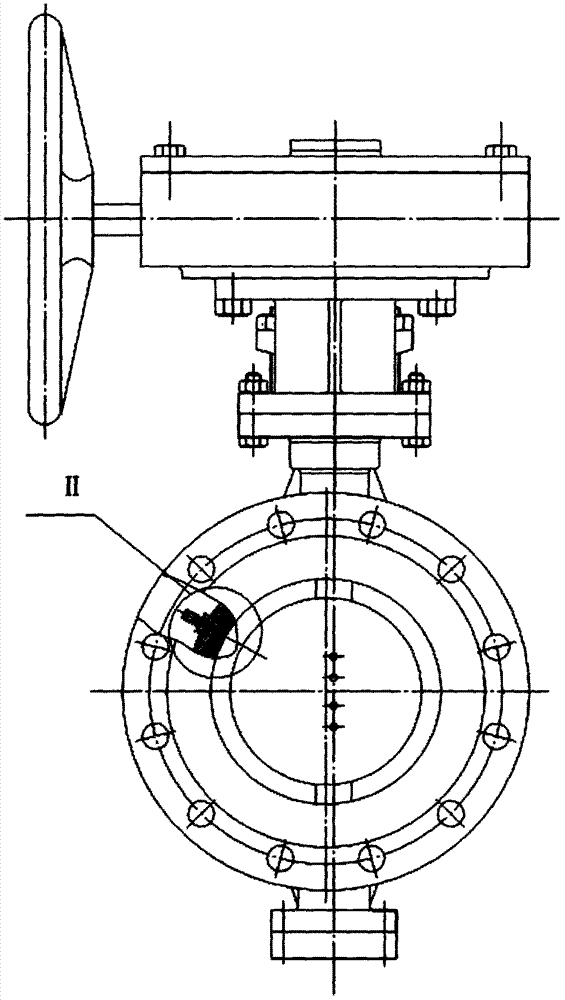

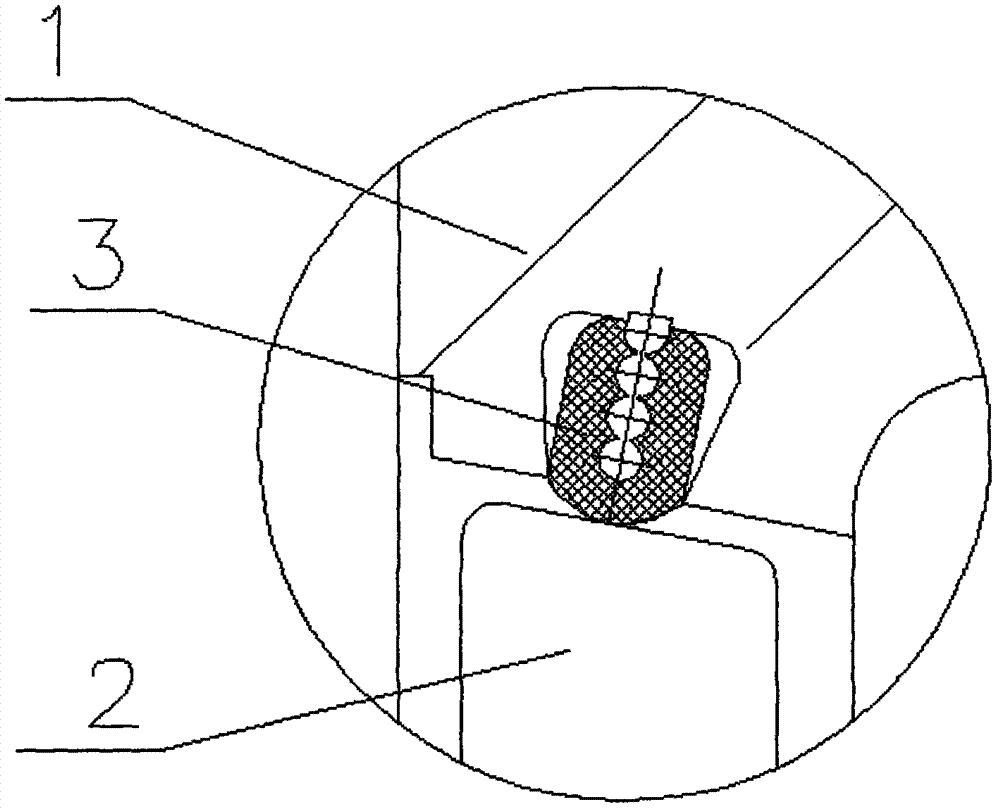

[0022] Such as Figure 1-5 As shown, the present invention provides a soft-sealed butterfly valve, the valve body 1 is provided with a valve seat, and the sealing side surface of the valve seat is provided with a groove with a large inside and a small mouth, and the groove is an annular shape connected end to end. Groove, that is, a 360° annular groove, the main part of which is in the shape of a rotating body, and a sealing ring whose top protrudes from the opening of the annular groove is provided in the annular groove, and the top end of the sealing ring protrudes from the opening of the annular groove. The part of the opening of the annular groove contacts and seals with the butterfly plate 2 of the butterfly valve, so that the valve seat and the butterfly plate form a sealing pair; the part of the sealing ring located in the annular groove is in contact with the annular groove The groove wall fits together, and the cross-section of the annular groove is preferably a trape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com