Pantograph monitoring system

A monitoring system and pantograph technology, applied in measurement devices, instruments, optical devices, etc., can solve problems such as low efficiency, affect performance, and prone to misjudgment, achieve high efficiency and accuracy, avoid pantograph-catenary accidents, The effect of reliable pantograph catenary accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

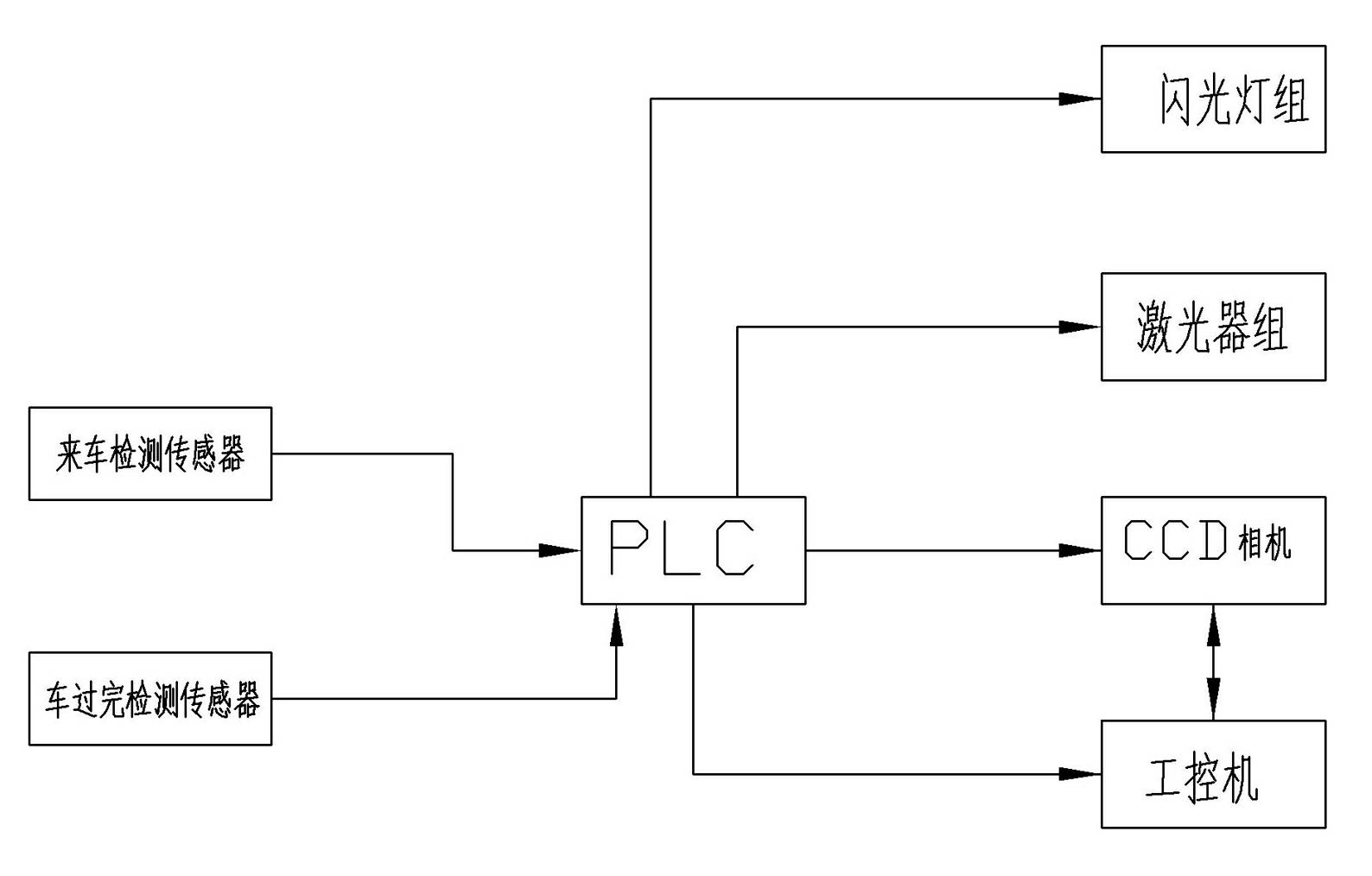

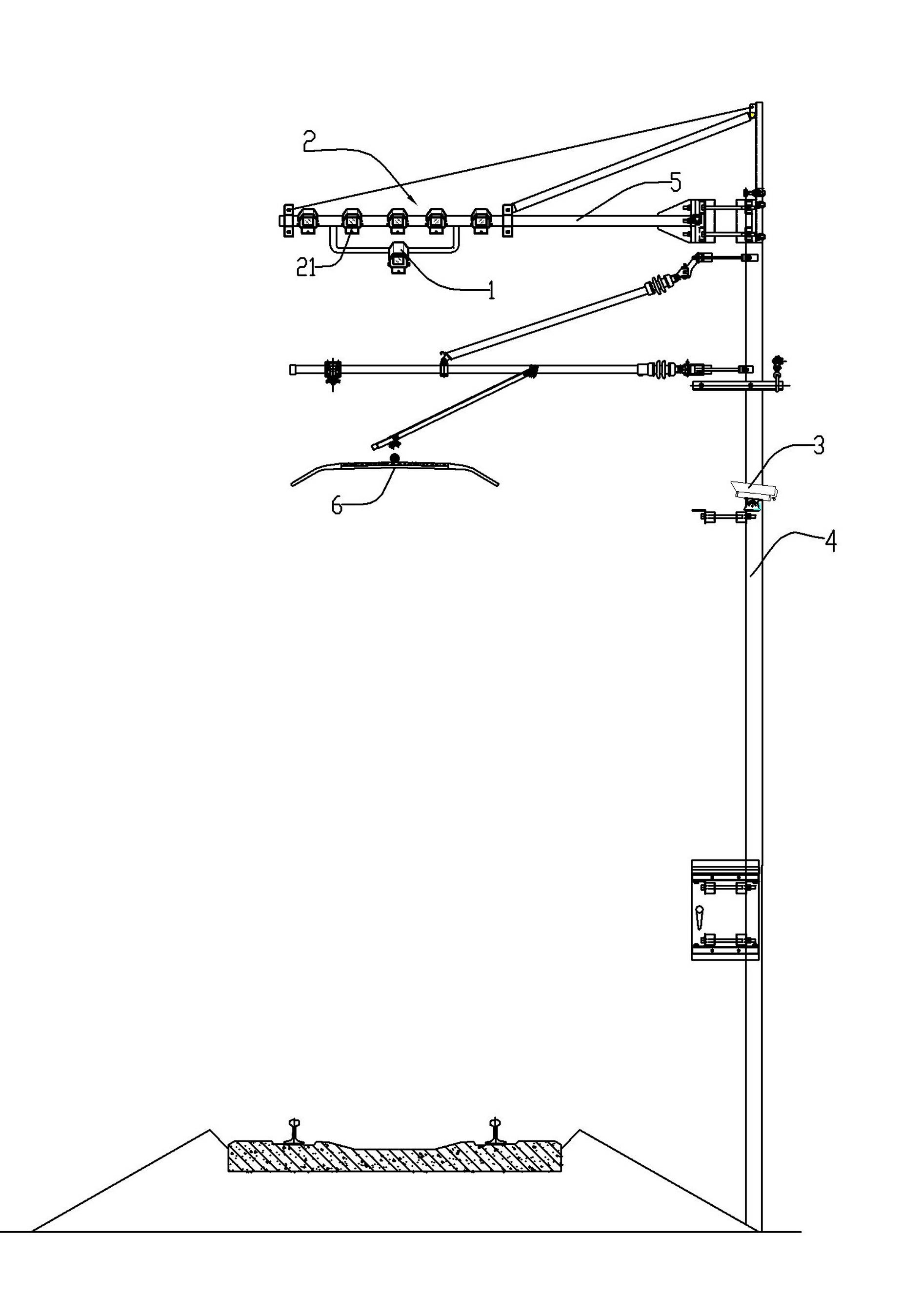

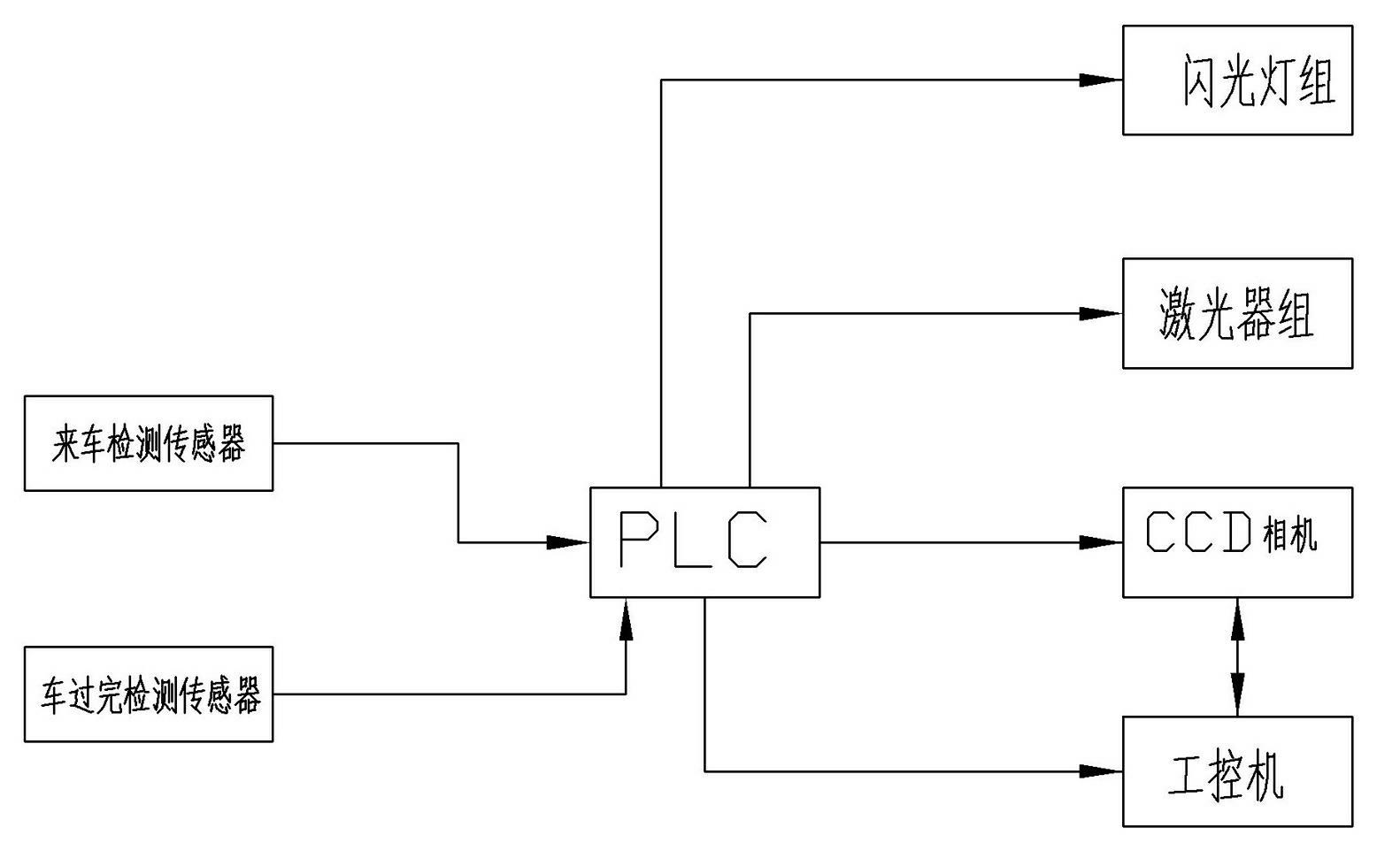

[0009] like figure 1 , figure 2 A pantograph monitoring system, including a CCD camera 1 installed obliquely above the monitoring place for taking pictures of the side of the pantograph head part, a laser group 2 for irradiating the side of the pantograph 6 at the monitoring place, Described laser group comprises a plurality of lasers 21, is arranged parallel to each other, and the top of monitoring place is also installed with the flashlight group 3 that is made of a plurality of flashlights; CCD camera, laser group and flashlight group connect PLC controller, by PLC controller To control its opening and closing, the PLC controller is also connected to an industrial computer. The industrial computer and the CCD camera are connected through a broadband network, and the photos transmitted by the CCD camera can be received through the broadband network, and stored and processed. Described laser group can be installed on the cantilever 5 that stretches out above contact line t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com