Preparation method of regenerated silk fibroin fiber and product thereof

A technology for regenerating silk fibroin and fibers, applied in the field of microfluidic spinning, can solve problems such as the inability to meet animal silk proteins, and achieve the effects of avoiding pollution and damage, reducing production costs, and controlling degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of regenerated silk fibroin fiber of the present invention, use the regenerated silk fibroin protein aqueous solution of 30% mass percentage concentration as spinning liquid, under the temperature condition of 30 ℃, inject the spinning liquid at the flow rate of 0.5 μ L / min In the microfluidic chip, after being extruded from the outlet of the microfluidic channel of the microfluidic chip, it is solidified into filaments in the air and wound on the upper roller; the air gap from the spinneret to the winding roller is 1cm, and the winding speed is 1cm / s .

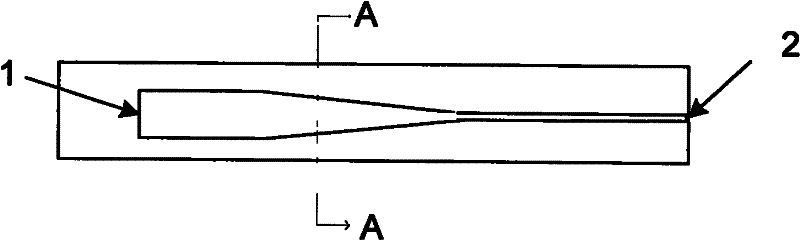

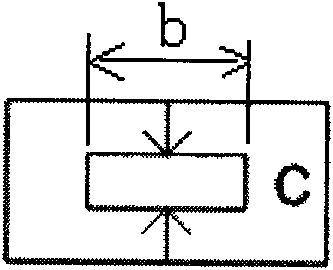

[0036] The microfluidic chip includes a substrate and a membrane, the membrane has grooves, and the grooved surface of the membrane is bonded to the substrate to form a microfluidic channel; as figure 1 and 2 As shown, the depth c of the whole microfluidic channel is equal to 10 μm, and the width b of the microfluidic channel gradually and continuously decreases from the inlet 1 to the outle...

Embodiment 2

[0040] A method for preparing regenerated silk fibroin fibers of the present invention uses an aqueous solution of regenerated silk fibroin with a mass percent concentration of 60% as the spinning liquid, and injects the spinning liquid into the microfiber at a flow rate of 10 μL / min at a temperature of 20°C. In the fluidic chip, after being extruded from the outlet of the microfluidic channel of the microfluidic chip, it is solidified into filaments in the air and wound on the upper roller; the air gap from the spinneret to the winding roller is 5 cm, and the winding speed is 5 cm / s.

[0041] The microfluidic chip includes a substrate and a membrane, the membrane has grooves, and the grooved surface of the membrane is bonded to the substrate to form a microfluidic channel; as figure 1 and 2 As shown, the entire depth c of the microfluidic channel is equal to 500 μm, and the width b of the microfluidic channel gradually and continuously decreases from the inlet 1 to the outlet...

Embodiment 3

[0045] A kind of preparation method of the regenerated silk fibroin fiber of the present invention, use the regenerated silk fibroin aqueous solution of 45% mass percentage concentration as the spinning solution, inject the spinning solution into the microfiber at a flow rate of 5 μL / min under the temperature condition of 10°C In the fluidic chip, after being extruded from the outlet of the microfluidic channel of the microfluidic chip, it is solidified into filaments in the air and wound on the upper roller; the air gap from the spinneret to the winding roller is 10 cm, and the winding speed is 3 cm / s.

[0046] The microfluidic chip includes a substrate and a diaphragm, the diaphragm has a groove, and the surface of the diaphragm with the groove is bonded to the substrate to form a microfluidic channel; the depth c of the whole process of the microfluidic channel is equal to 100 μm, the width b of the microfluidic channel gradually and continuously decreases from the inlet 1 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com