High-strength plastic-steel door/window

A plastic-steel door and window, high-strength technology, applied in the installation of window glass, wing frame and other directions, can solve the problems of insufficient strength and insufficient reinforcement of plastic-steel doors and windows, and achieve the effect of high strength and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

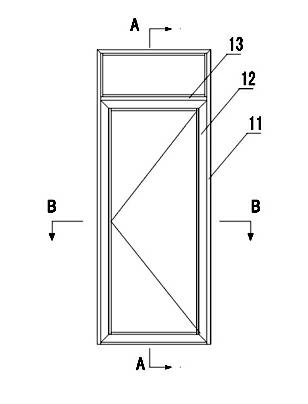

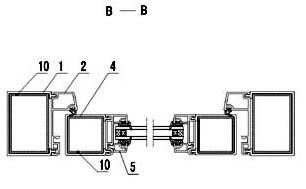

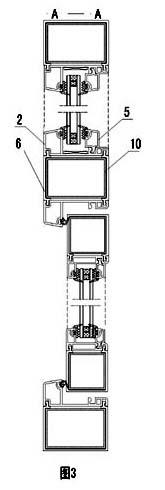

[0016] The general idea of the present invention is: buckle the plastic-steel section bar on the steel pipe of the integrally welded steel door and window frame skeleton, the integral steel door and window frame skeleton acts as a rigid support, and the plastic-steel section bar plays the role of protecting the integral steel window frame skeleton and installing glass. The present invention is composed of a steel window frame frame 11 integrally welded, a steel fan frame frame 12 integrally welded, plastic steel profiles and glass, and the plastic steel profiles are buckled on the steel pipes of the steel window frame frame and the steel fan frame frame, and the glass It is installed on plastic steel profiles, and the steel fan frame frame is installed on the steel window frame frame.

[0017] Take high-strength single casement doors and windows as an example, such as figure 1 As shown, the single casement doors and windows are mainly composed of an integral door and window ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com