Combined water-drainage pre-filtering air intake pipe for heavy automobile

A heavy-duty vehicle, combined technology, applied in the field of air intake system, to achieve the effect of improving efficiency, small resistance and reducing total resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

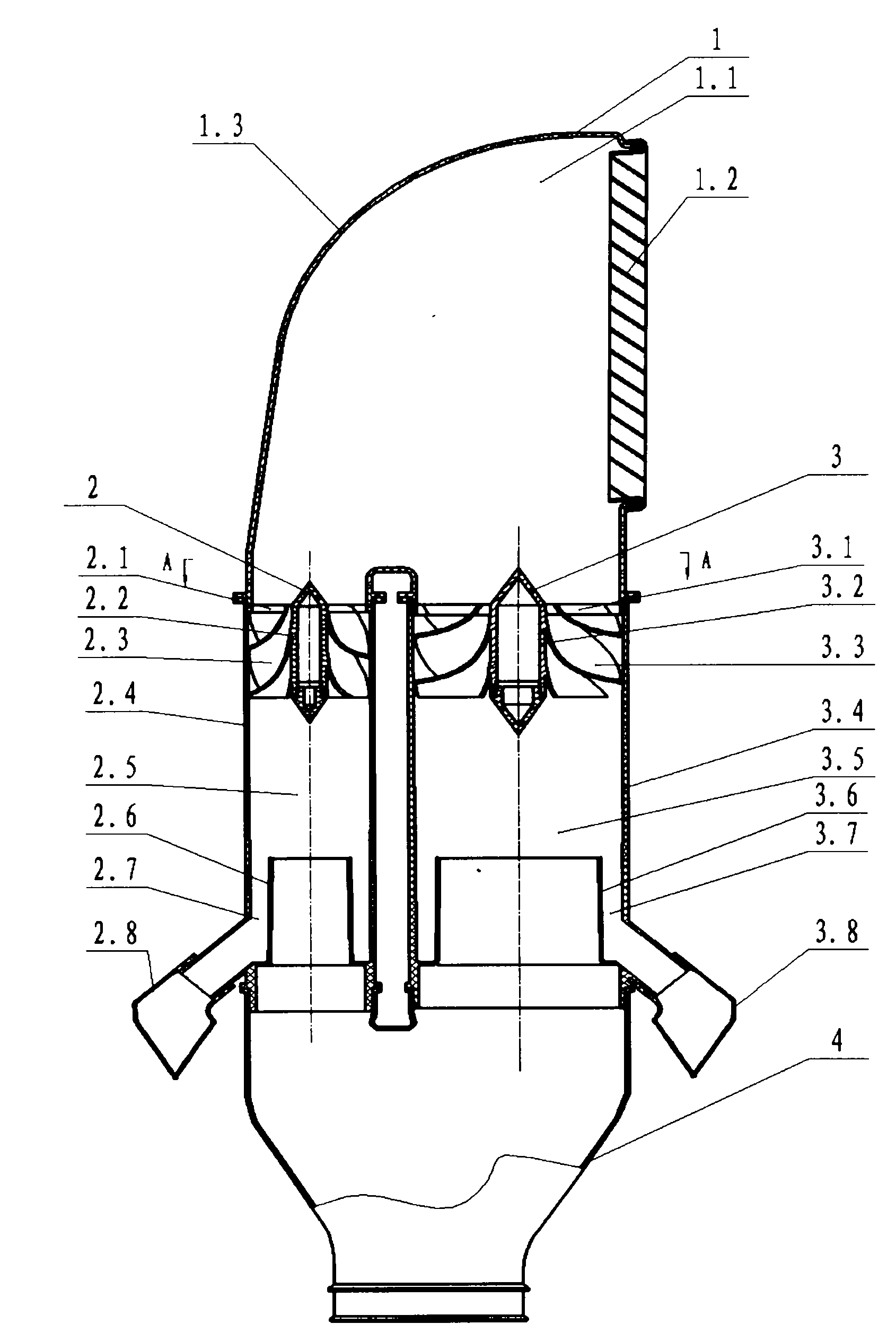

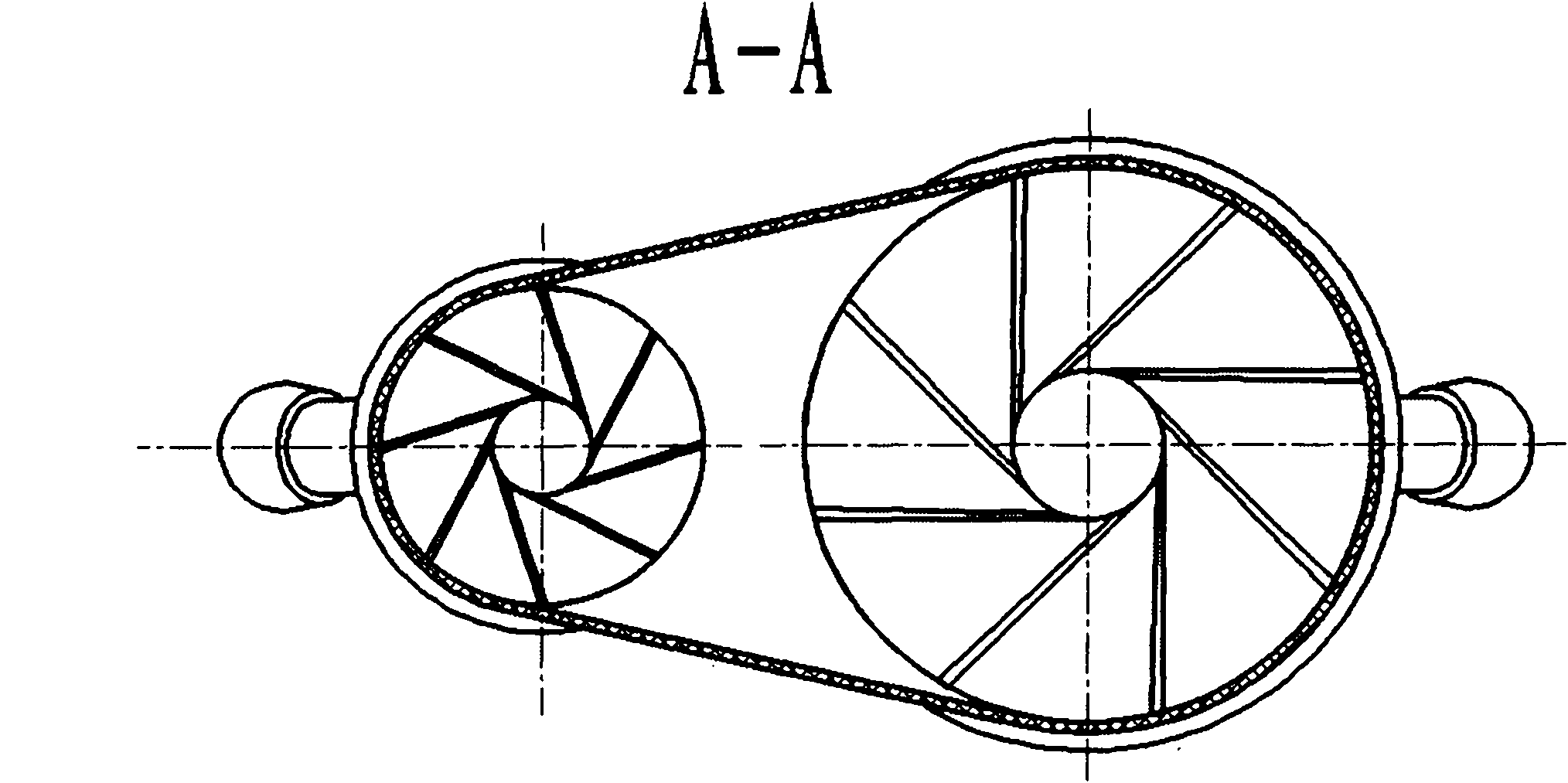

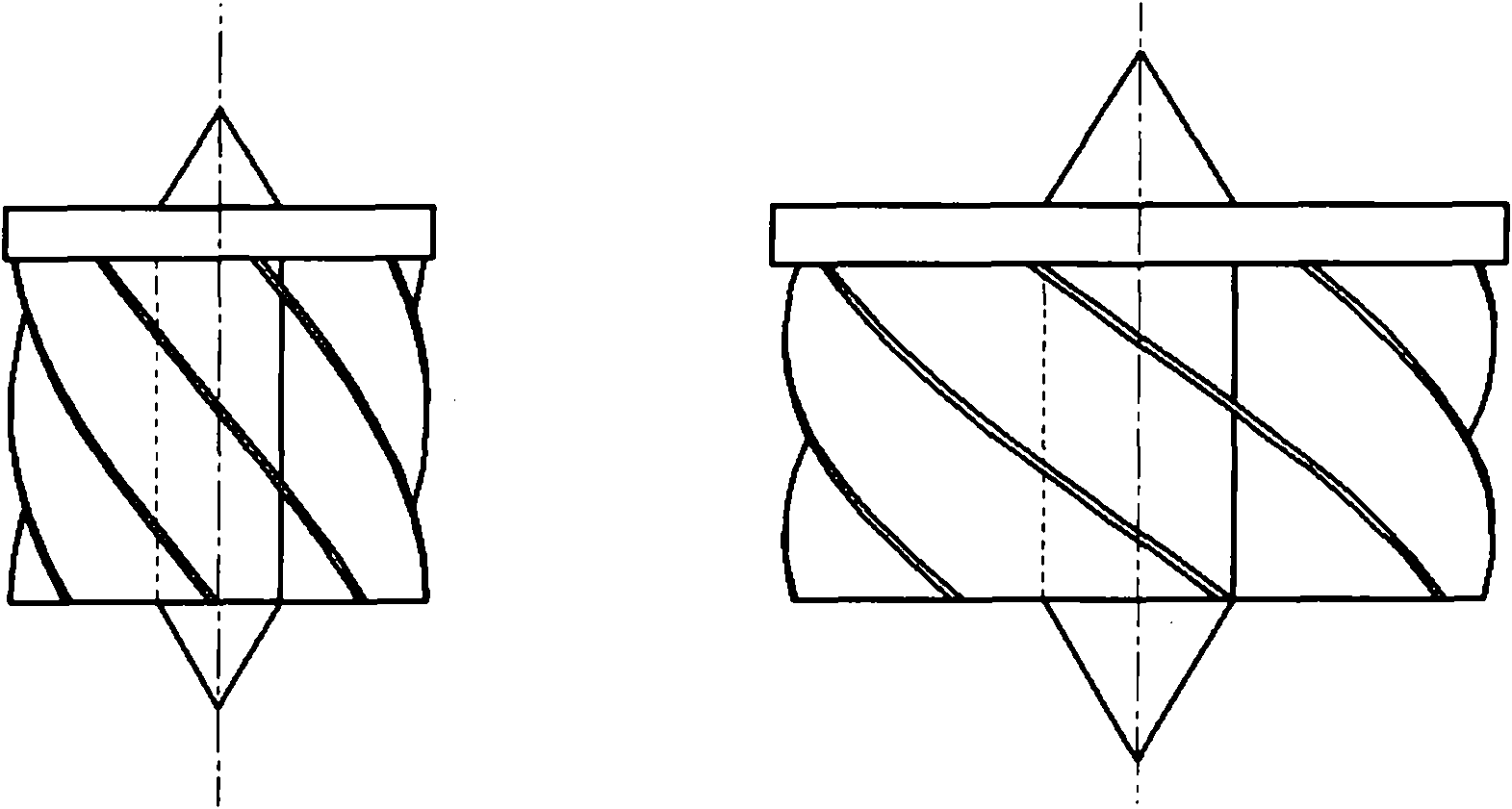

[0024] Embodiment 1, see attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 1. The heavy-duty vehicle combined drainage pre-filter intake pipe includes an inertial separator 1, a cyclone, an air intake grille 1.2, and a connecting pipe 4. The air intake grille in the inertial separator is installed on one side of the inertial separation chamber 1.1, and the air intake The other side corresponding to the grille is provided with a guide screen 1.3, and the lower end of the inertial separation chamber is fixedly connected with a small cyclone 2 and a large cyclone 3, the small cyclone is located on the side of the guide screen, and the large cyclone is located On one side of the grid, the ratio of the cross-sectional area of the large and small cyclones is 2.25:1. The diversion screen is formed by two tangent arcs with different radii. The cross section of the diversion screen is a semicircle, and its inner radius is the same as that of the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com