Method for producing a prefabricated part from an unmachined part by means of a milling tool

A technology for milling cutters and blanks, applied in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of extending additional paths, prolonging processing time, etc., to achieve the effect of protecting tools, improving process safety, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

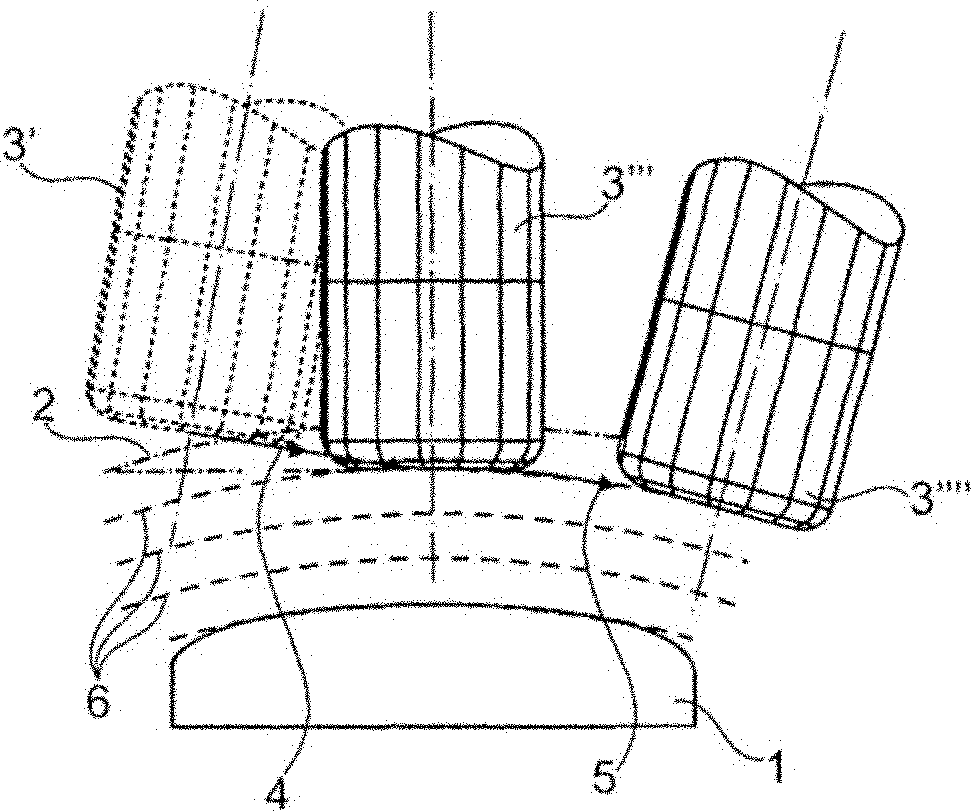

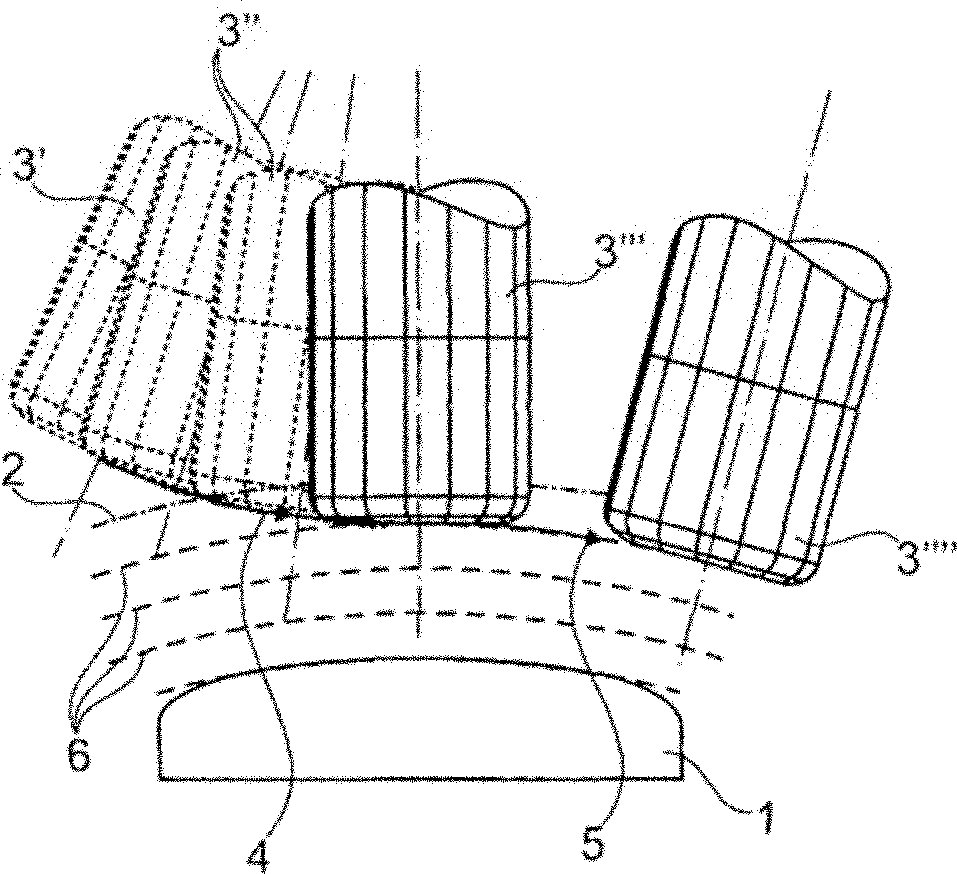

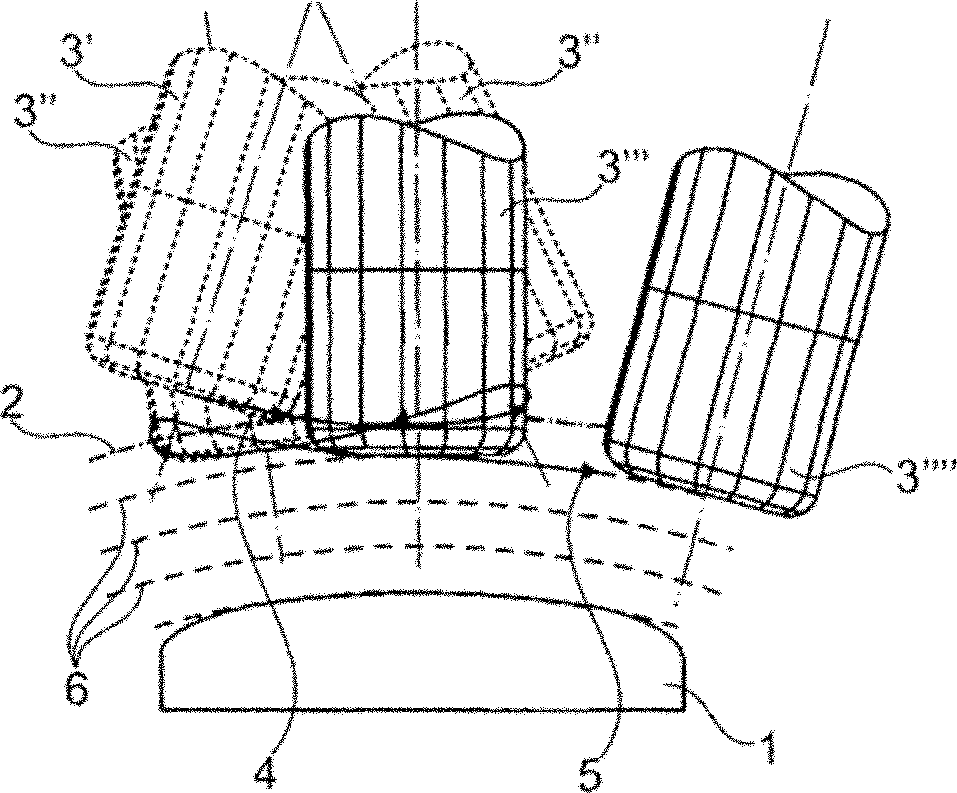

[0033] In the following description of the different embodiments of the method according to the invention for producing a finished part 1 from a blank 2 by means of a milling cutter 3 , corresponding or identical components are each given the same reference numerals.

[0034] Here, the milling cutter 3' is at the start of the insertion path, the milling cutter 3'' is at the end of the insertion path, the milling cutter 3'" is at the end of the insertion path or the starting point of subsequent machining, and the milling cutter 3'"" is at the subsequent during processing.

[0035] The insertion path of the milling cutter 3, i.e. the tool path during insertion, is marked with the reference numeral 4, while the machining path of the milling cutter 3, i.e. the milling cutter path during machining, is indicated with the reference numeral 5, and the reference numeral 6 indicates the difference in machining. depth of infeed.

[0036] exist Figures 1a to 1c The method according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com