Vehicle as well as method and device for leveling hydro-pneumatic suspension of same

A technology of oil-gas suspension and leveling device, applied in the field of vehicle leveling, can solve the problems of overshoot, low leveling efficiency, and great influence of leveling quality operation skills, so as to improve ride comfort and improve vibration reduction. performance, the effect of improving the leveling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The core of the present invention is to provide a leveling method of an oil-pneumatic suspension, which can automatically level multiple suspension cylinders at the same time, so that the leveling efficiency and quality of the oil-pneumatic suspension are significantly improved. Another core of the present invention is to provide a leveling device using the above-mentioned leveling method and a vehicle with the device, the damping performance and riding comfort of which are improved.

[0047] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

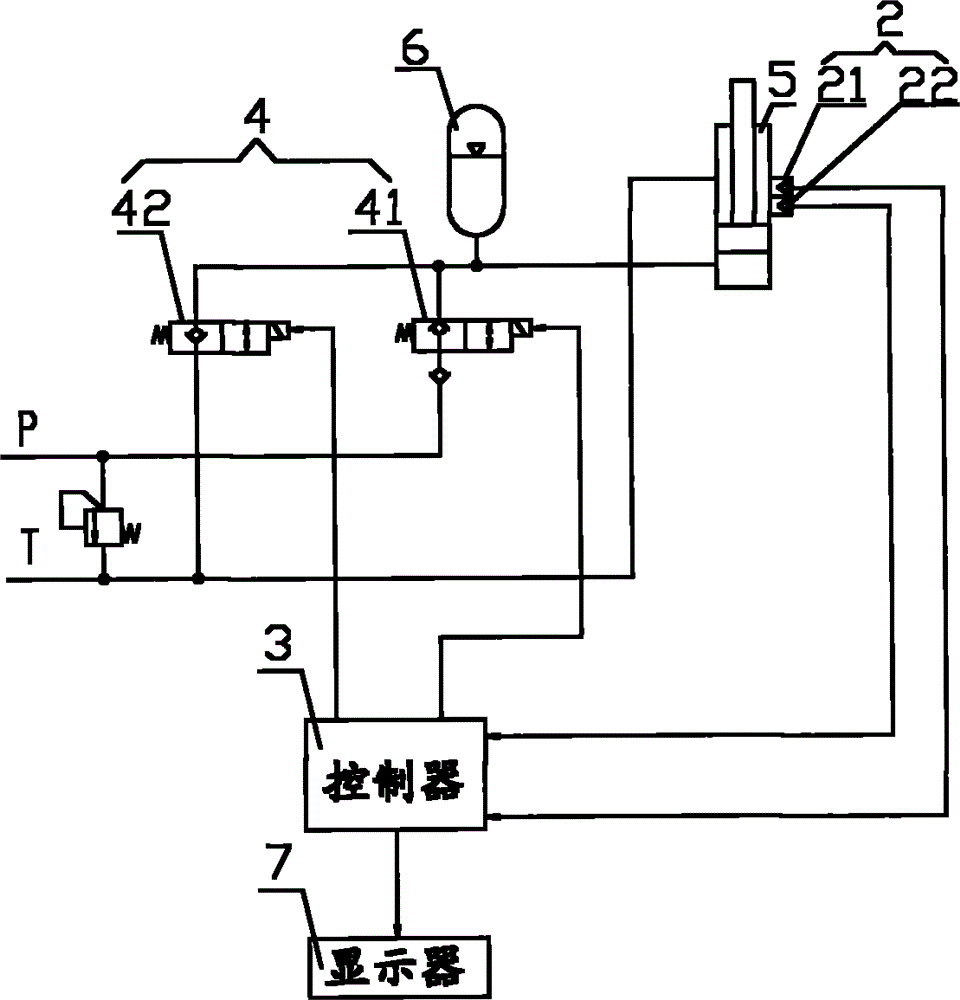

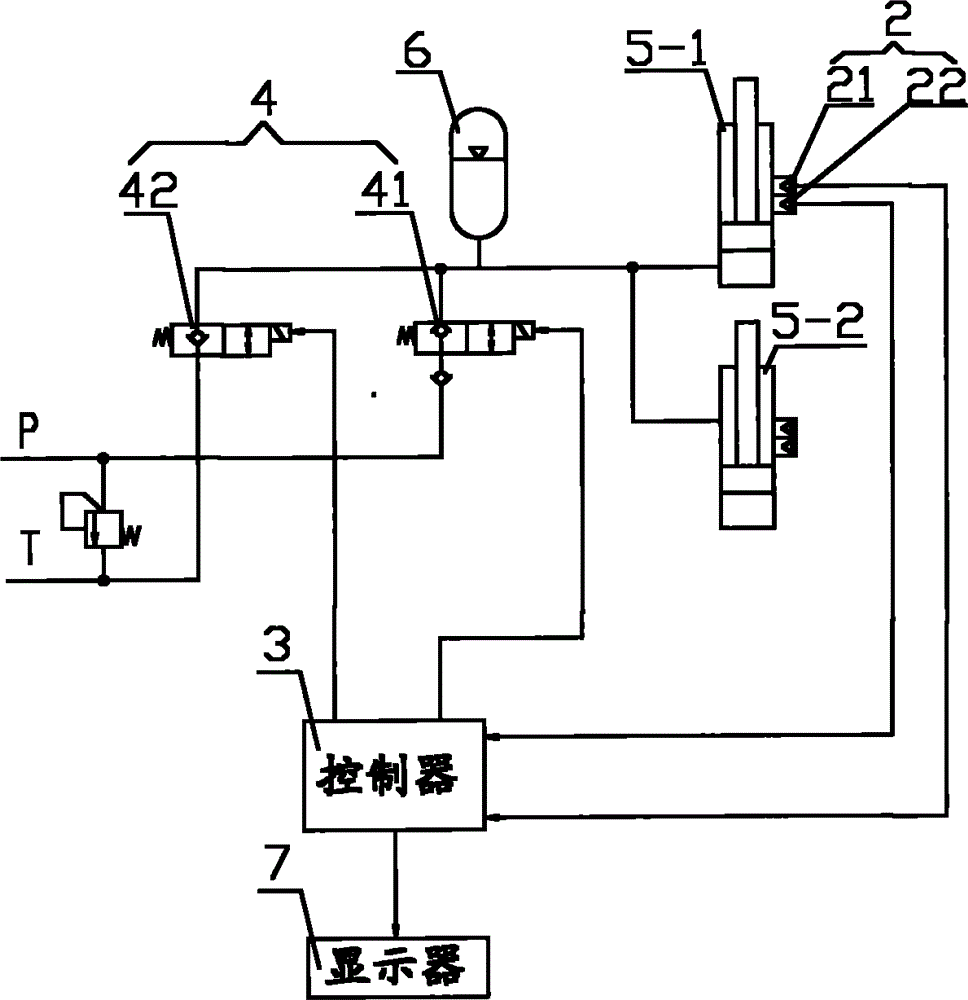

[0048] Please refer to figure 2 , figure 2 It is a hydraulic circuit schematic diagram of a specific embodiment of the oil-pneumatic suspension leveling device provided by the present invention.

[0049] The oil-pneumatic suspension levelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com