Method for eliminating torsion inertia force of double-rotor piston engine

A piston engine, torsional inertia technology, applied in the direction of internal combustion piston engine, inertial force compensation, combustion engine, etc., can solve the problems of low power source power density, low power density, poor fuel economy, etc., to speed up the practical process, eliminate Torsional inertial force, effects in a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

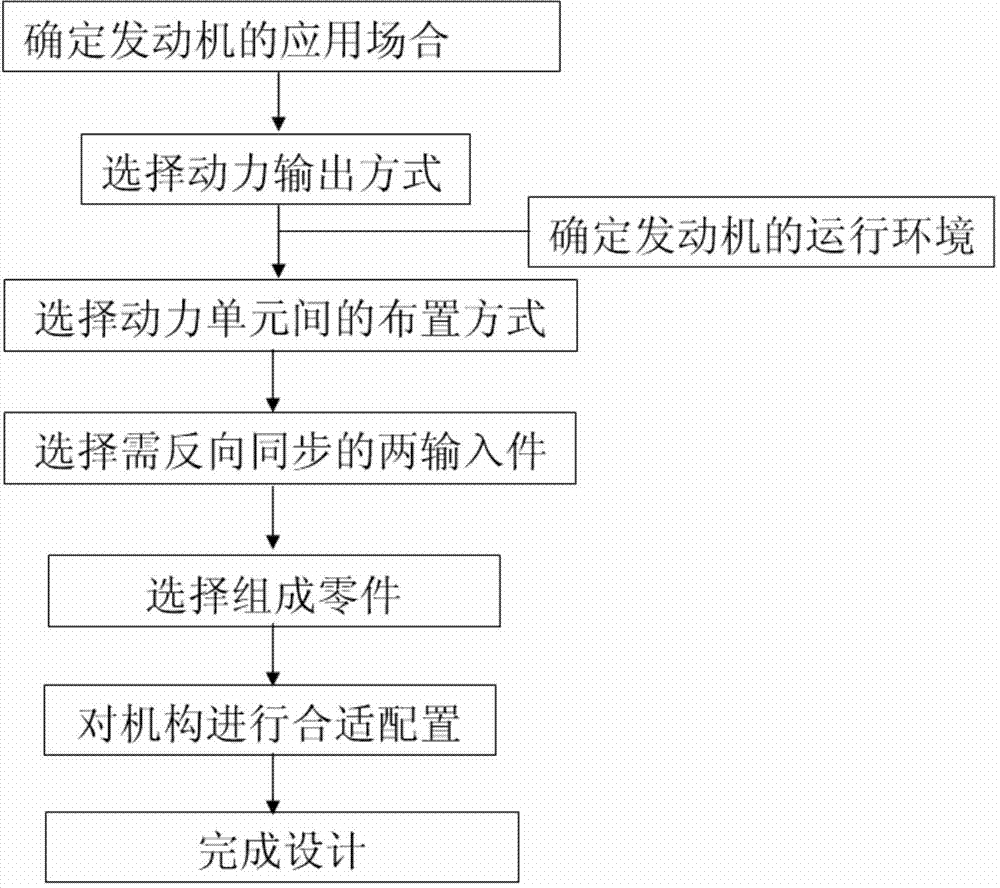

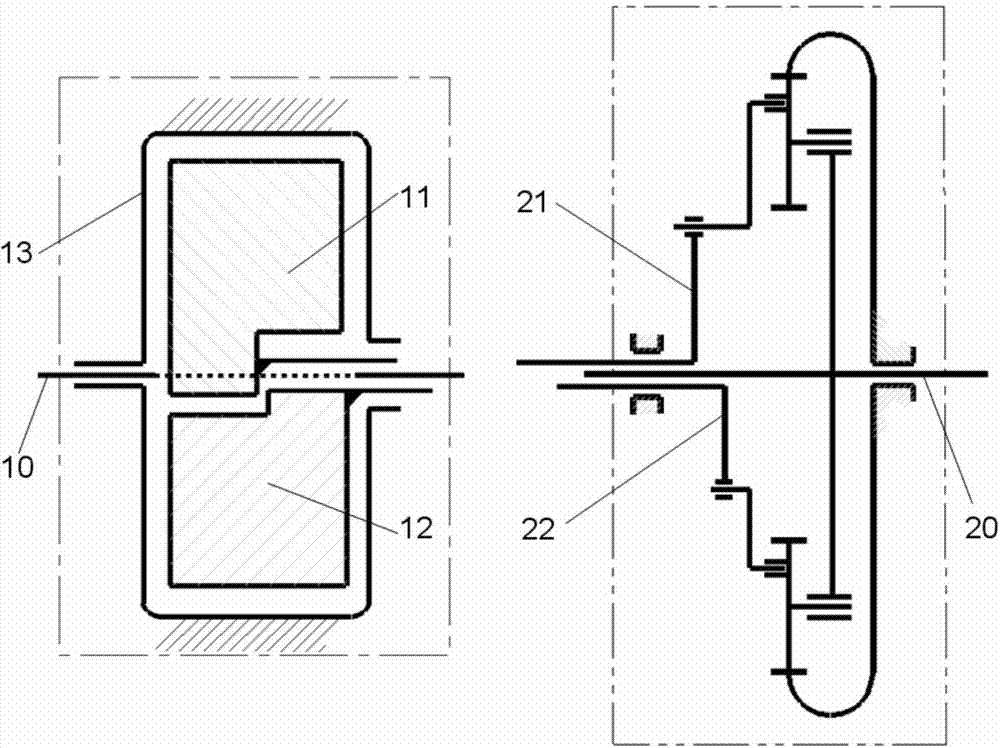

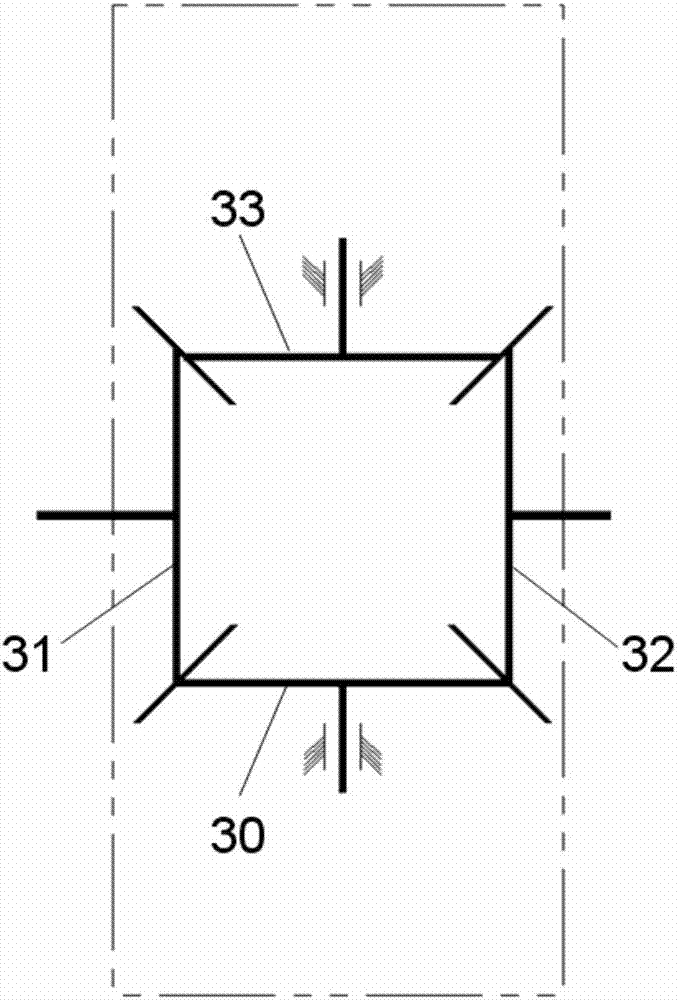

[0032] The invention discloses a method for eliminating the torsional inertial force of a dual-rotor piston engine. The dual-rotor piston engine is a power unit composed of a power cylinder assembly 1 and a differential drive assembly 2 connected thereto. Between the units, offset the torsional inertial force generated by the non-uniform rotation of the parts of the power unit. By setting a reverse synchronous component between two sets of power cylinder components or between two differential drive components, the inherent torsional inertia force problem of each dual-rotor piston engine is solved, thereby making the advantages of this type of engine more obvious and accelerating its practical application process.

[0033] The method mainly includes the following steps:

[0034] ① Select the power output mode: select the appropriate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com