Oil purifier for motor vehicle

A technology for oil purifiers and motor vehicles, applied in machines/engines, chemical instruments and methods, mechanical equipment, etc., can solve the problems of limited filter particle size, high manufacturing cost, and high viscosity of diesel oil when cold Flexibility in use, low emission characteristics, and the effect of improving thermal evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

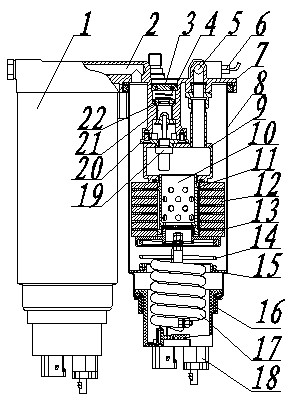

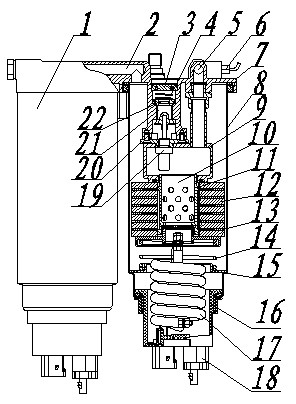

[0025] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0026] by attaching figure 1 It can be seen that the motor vehicle oil purifier of the present invention includes a filter seat 7 connected in sequence, an oil storage cup 8, a water storage cup 16, a water discharge valve assembly 18, and a thermal controller assembly located in the oil storage cup 8, The magnetic filter assembly, and the infrared radiation heater 17 located in the water storage cup 16; the magnetic filter assembly is connected with the thermal controller assembly through the purification connector 9, and the support spring 14 provided on the support plate 15 and the support plate 15 It is connected with the infrared radiation heater 17.

[0027] The magnetic filter element assembly includes a support 11, a filter element 10, a strong magnetic sheet 12 and a silk f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com