Torsional vibration damper or torsionally flexible coupling

A technology of torsional vibration damper and torsional elasticity, which is applied in the direction of elastic couplings, springs/shock absorbers, couplings, etc., and can solve the problem of vibration damping effect of torsional vibration dampers lacking intermediate blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

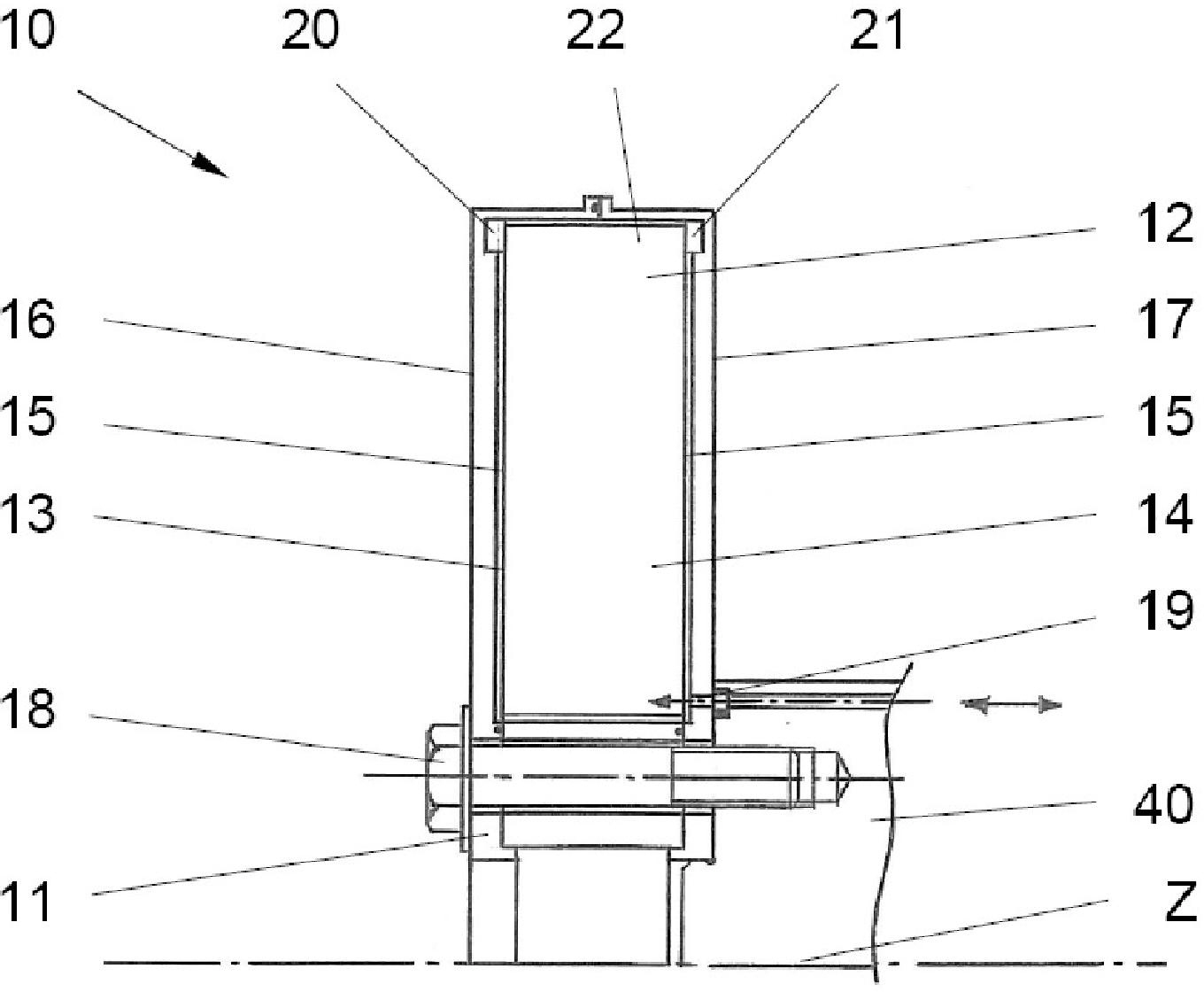

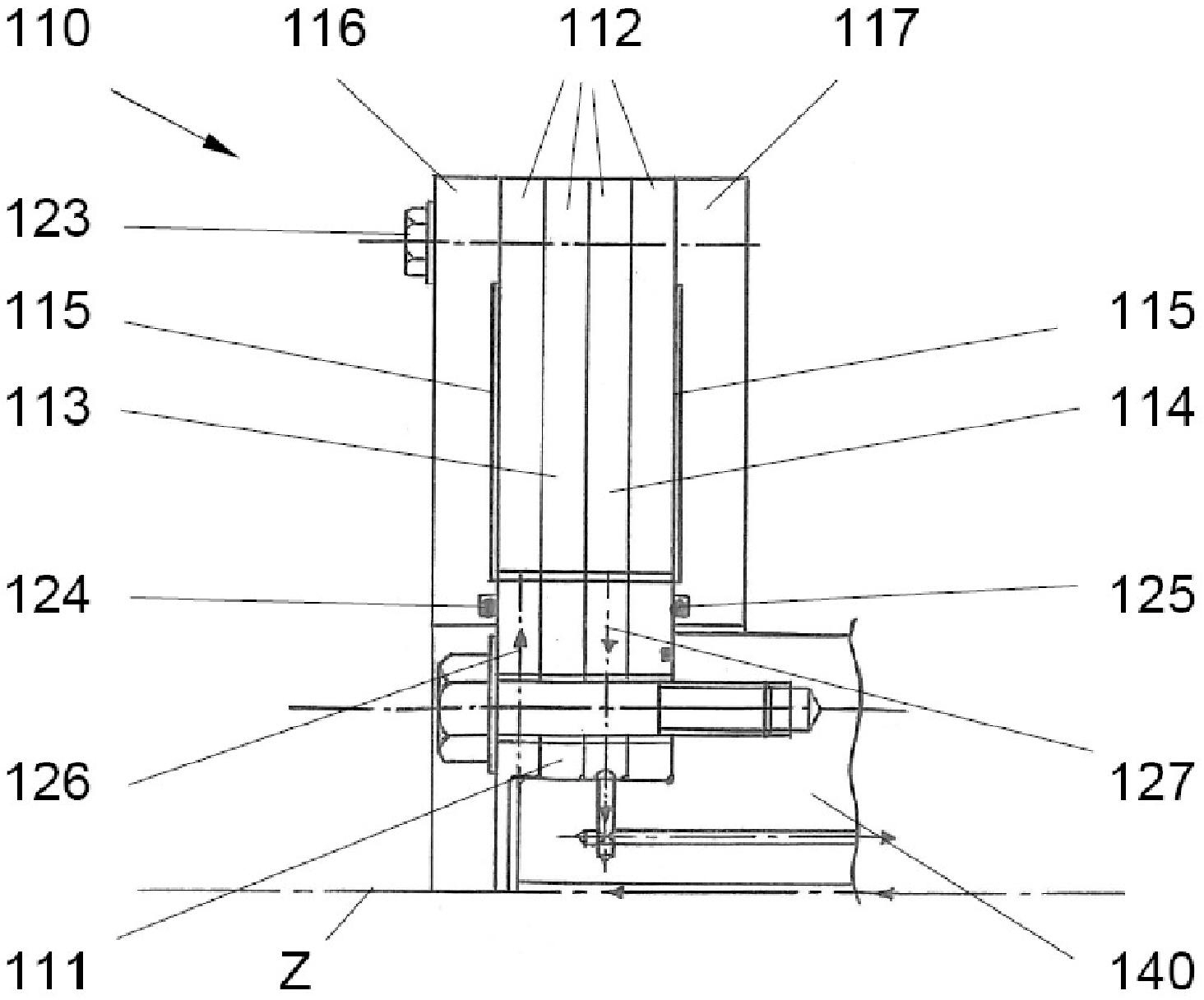

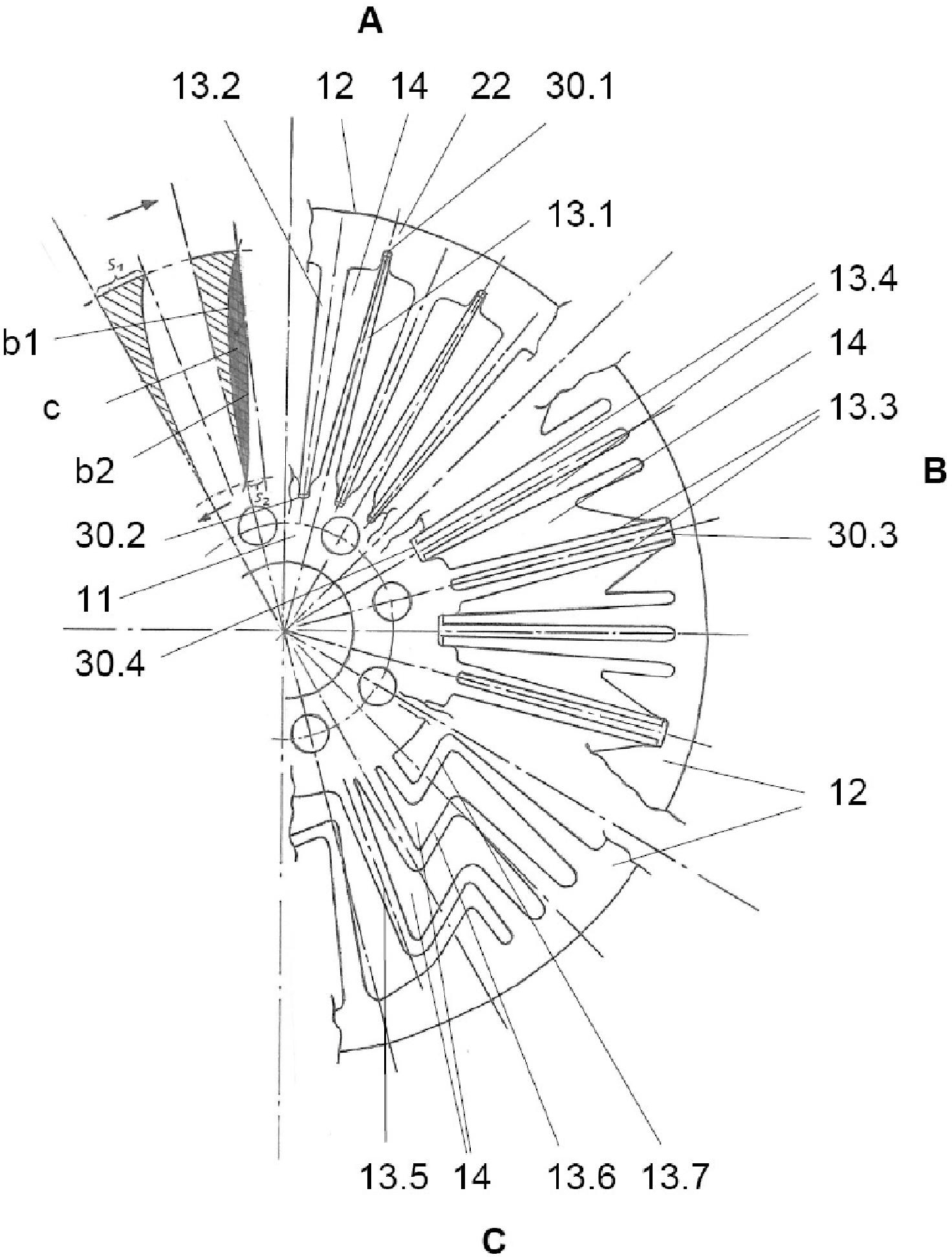

[0028] like figure 1 As shown, a torsional vibration damper 10 connected to a rotating member, such as a crankshaft 40, comprises a rotationally symmetric inner member 11 having an axis of rotation Z, and an outer member 12 coaxial with the inner member 11, the outer member 12 being The ring surrounds the inner part 11 . The inner part 11 and the outer part 12 are connected by a plurality of spring assemblies 13 that transmit torque. The spring assemblies 13 divide the space formed between the inner part 11 and the outer part 12 into a plurality of continuous parts distributed on the circumference of the shock absorber 10 . Cavity 14. The space is annular and concentric with the axis of rotation Z. The cavity 14 is filled with viscous medium and is connected through the overflow channel 15 . When the inner part 11 and the outer part 12 rotate relative to each other, the spring assembly 13 is deformed, and the damping medium is transferred through the overflow channel 15 , r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com