Bionic joint device of closed lubrication

A bionic joint and bionic technology, applied in the field of robotics, can solve the problems of mechanical joints and bionic joints of robots, which are difficult to apply to joint mechanisms of human body and size changes, and do not imitate the shape of human bones, etc., so as to achieve easy replacement , to ensure stability and safety, and to prevent longitudinal displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

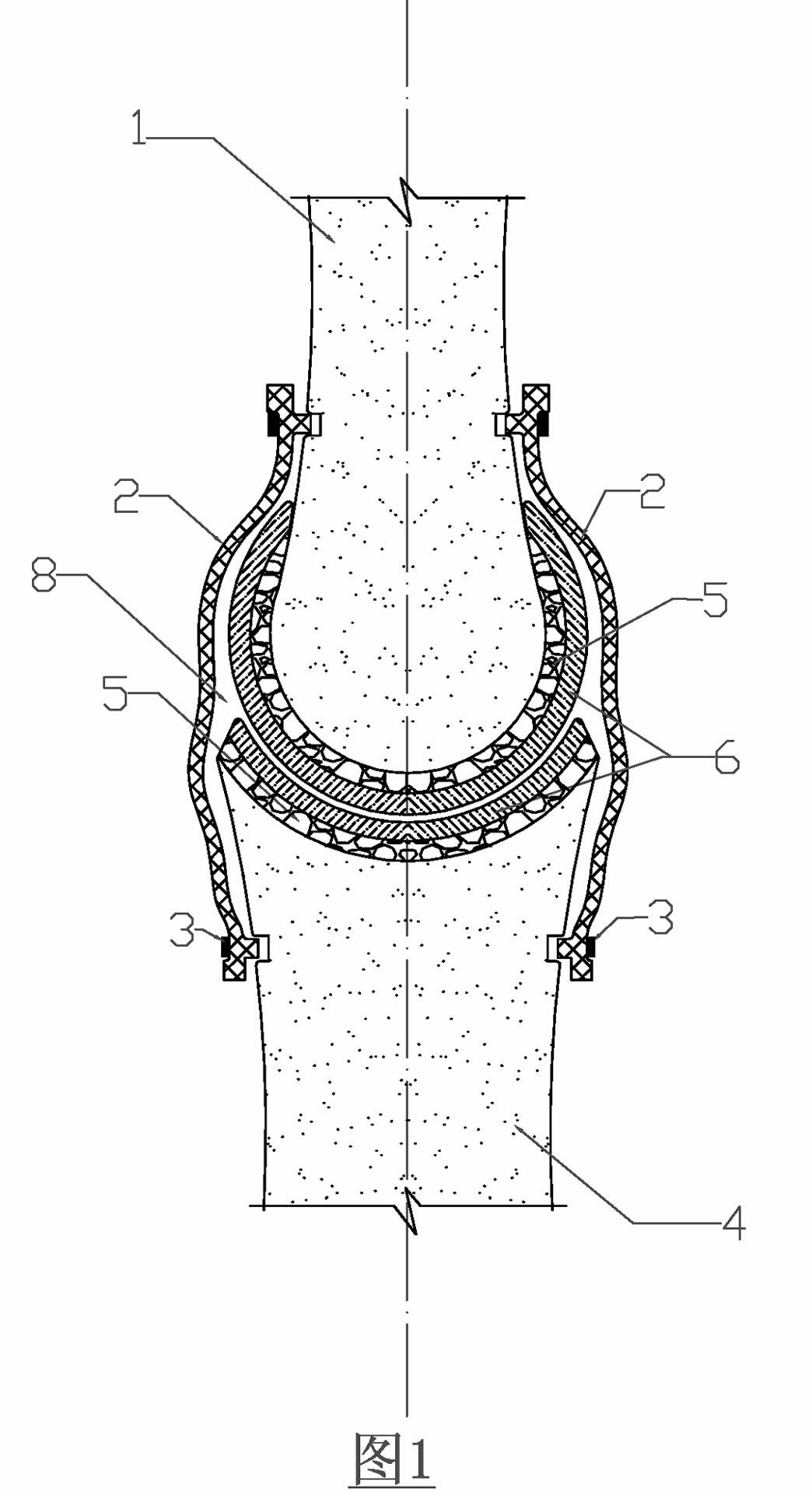

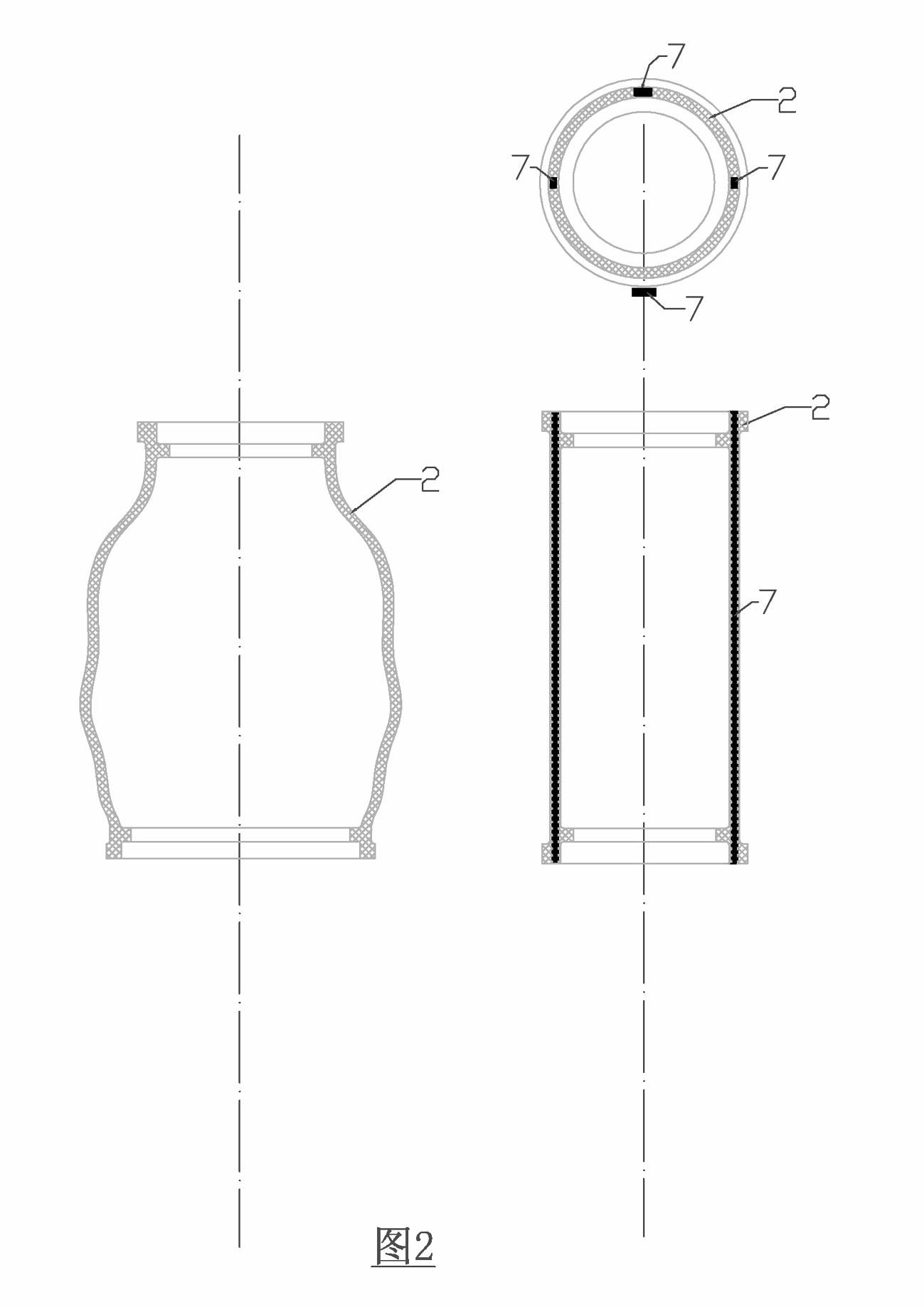

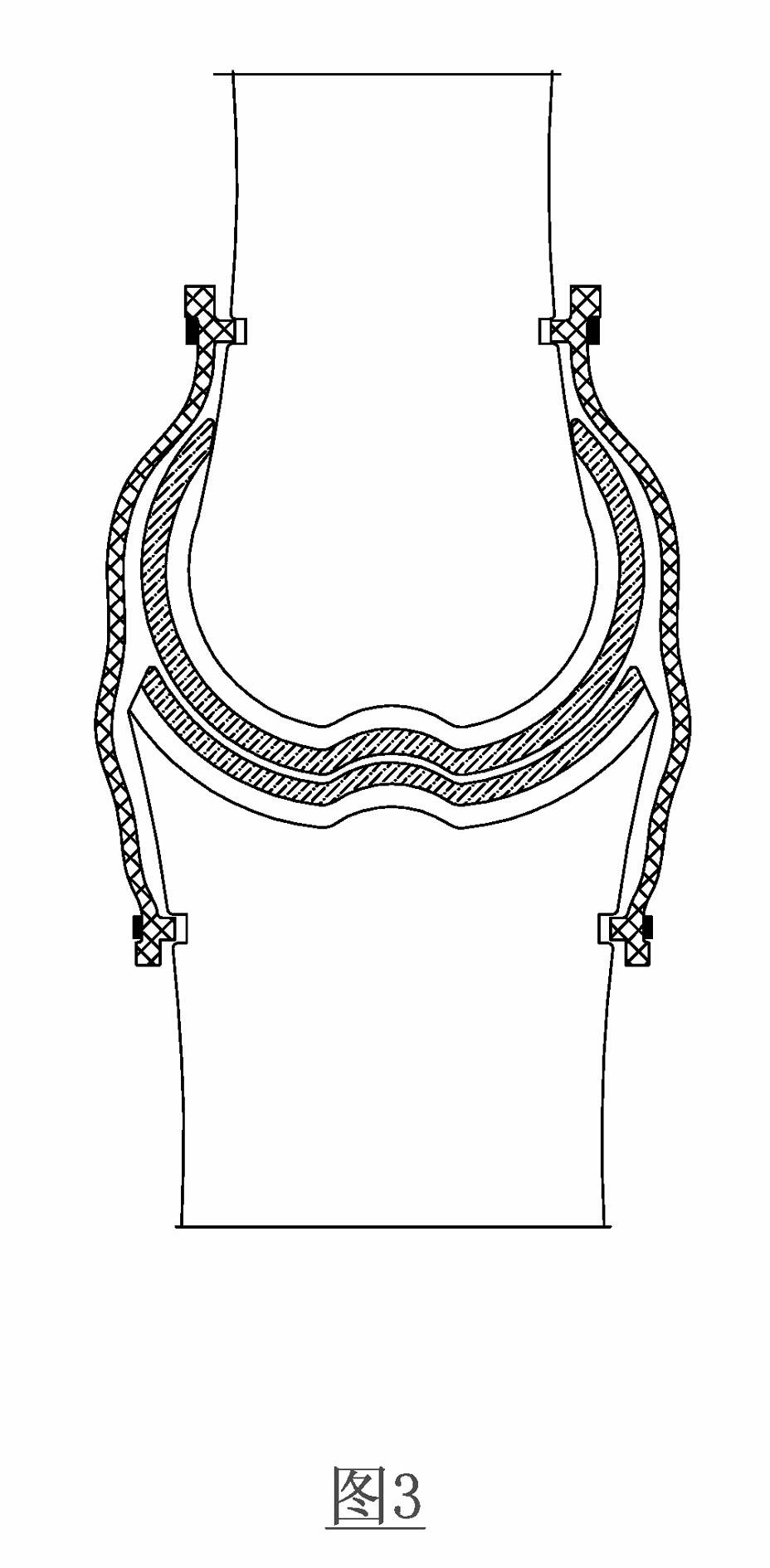

[0012] Closed lubricated bionic joint devices, such as figure 1 As shown, the main body bionic bone 1, the driven bionic bone 4, the elastic easy-to-expandable cavity housing 2 ( figure 2 Separate section representation), cavity sealing clamp 3, elastic shockproof material 5, high-strength wear-resistant self-lubricating material 6 and, figure 2 Medium and strong non-elastic limit connection 7 (in figure 2 It can be placed in the elastic telescopic cavity or placed outside for connection and fixing) to form a closed and lubricated bionic joint device, and the closed and lubricated bionic joint device is filled with grease 8 to adapt to the lubrication of high-strength wear-resistant materials 6 , maintain the lubrication and friction between the main bionic bone 1 and the driven bionic bone 4, protect the lubrication and high-strength wear-resistant self-lubricating material 6 to ensure good bending, twisting and sliding, and the elastic telescopic cavity shell 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com