Glued laminated timber and production and utilization method thereof

A manufacturing method and integrated wood technology, which can be applied to other household appliances, applications, household components, etc., can solve the problems of narrow veneer width, low overall board rate, and many broken boards, so as to save resources and improve production efficiency , The effect of expanding the supply of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment one integrated wood structure

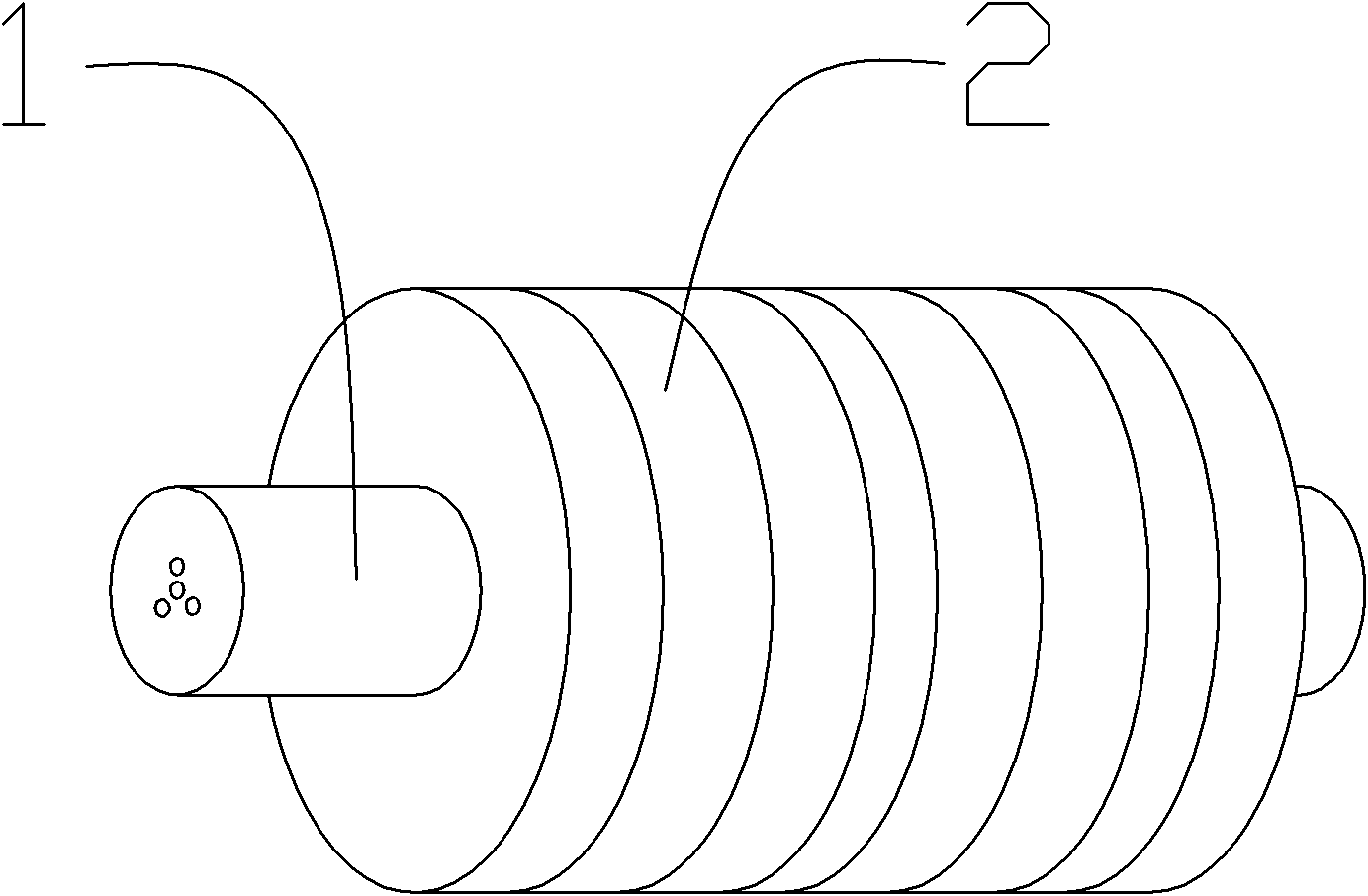

[0042] Such as figure 1 As shown, the integrated wood described in the application of the present invention, viewed as a whole, is composed of a cylindrical core 1 in the center and a plurality of annular integrated wood monomers 2 sleeved outside the core 1. The core 1. The two ends are closed, and the two ends of the core body 1 are provided with a positioning device corresponding to the clamping head of the rotary cutting machine.

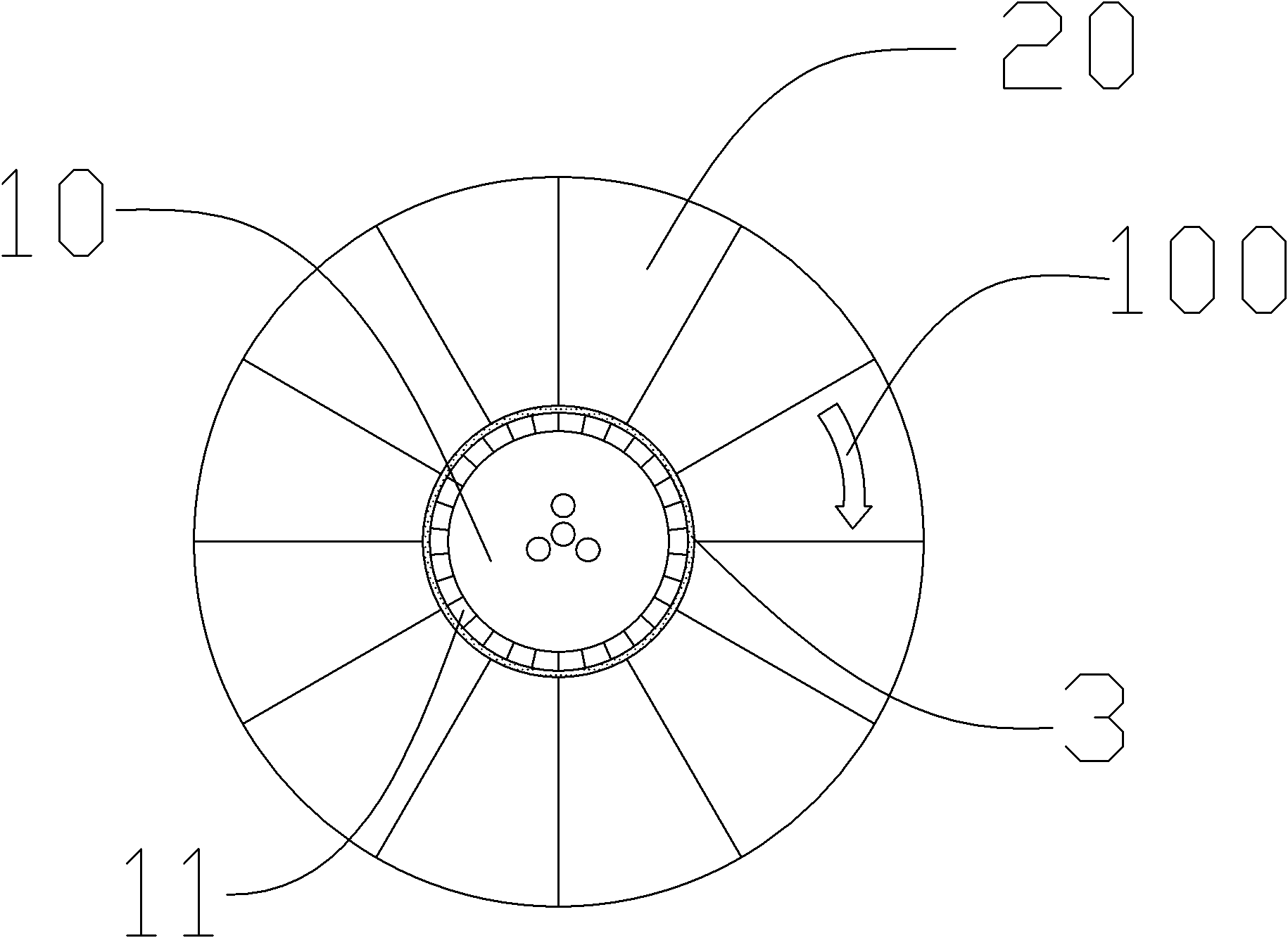

[0043] Such as figure 2 , the core body 1 is composed of a metal inner core 10 closed at both ends in the center and a circular wooden structure layer 11 close to the metal inner core 10; the inner and outer rings of each annular integrated wooden unit 2 It is a concentric ring, wherein the diameter of the outer ring of each integrated wood monomer 2 is equal, and the diameter of the inner ring is slightly larger than the diameter of the integrated wood core 1. Preferably, the distance between t...

Embodiment 2

[0046] Embodiment 2 The processing and manufacture of integrated wood

[0047] The integrated wood described in the application of the present invention is processed by the following steps:

[0048] 1. The production of the core body: take a metal inner core with closed columns at both ends, and inlay or glue a layer of wood structure around the metal inner core;

[0049] 2. Production of boards: process logs, short boards, and low-quality logs into trimmed boards of various thicknesses with a thickness of 1-8 cm;

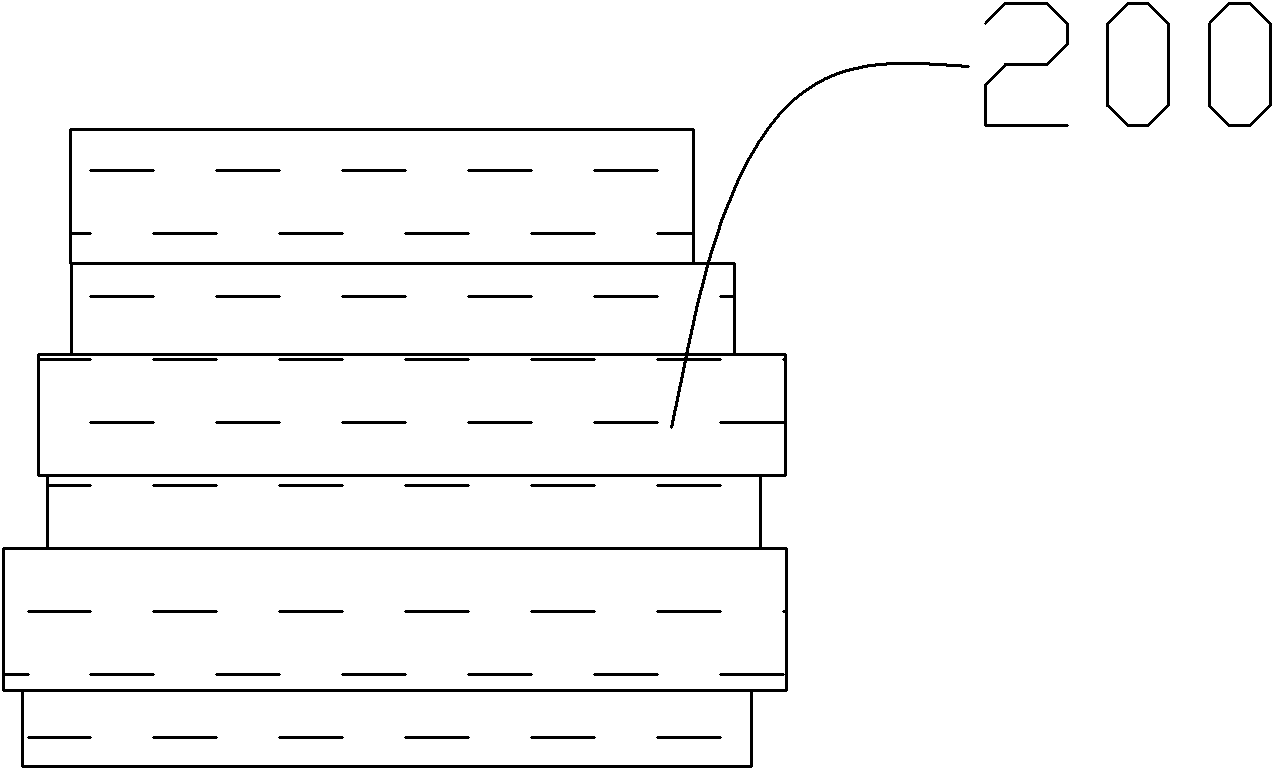

[0050] 3. Production of fan-shaped blanks: multiple panels of equal thickness are glued together to form a whole board, and then cut to form fan-shaped blanks with integrated wood monomers. The central angle of each fan-shaped blank is between 5°-25° , the inner and outer arcs of the fan-shaped blank are concentric arcs, the diameter of the outer arc is equal to the diameter of the integrated wood to be obtained, the diameter of the inner arc is slightly larger th...

Embodiment 3

[0058] Embodiment 3 Utilization method of integrated wood

[0059] The application of the present invention also provides the utilization method of the integrated wood. When using a rotary cutter to make veneers, the rotational direction of the integrated wood is clockwise, that is, it moves in the direction of the direction mark arrow, and the rotary knife of the rotary cutter rotates clockwise. The feeding direction moves opposite to each other, and the processing ends when the rotary cutting reaches the wood structure layer of the integrated wood core body, and the integrated wood core body can be reused.

[0060] To sum up, the application of the present invention provides a kind of integrated wood with a large diameter that can turn waste into treasure, and short and small boards and low-quality wood can be cut and spliced reasonably to obtain large-diameter integrated wood, which can replace naturally grown large-diameter logs. It is processed into high-quality veneer ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap