Oil-based inkjet printing method and ink set

A printing method and technology of oil-based ink, applied in the directions of printing, ink, copying/marking method, etc., can solve the problems of printing dot bleeding, increase of printing through, and no inhibition of ink smear, etc., to prevent printing and bleeding. , the effect of increasing the printing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

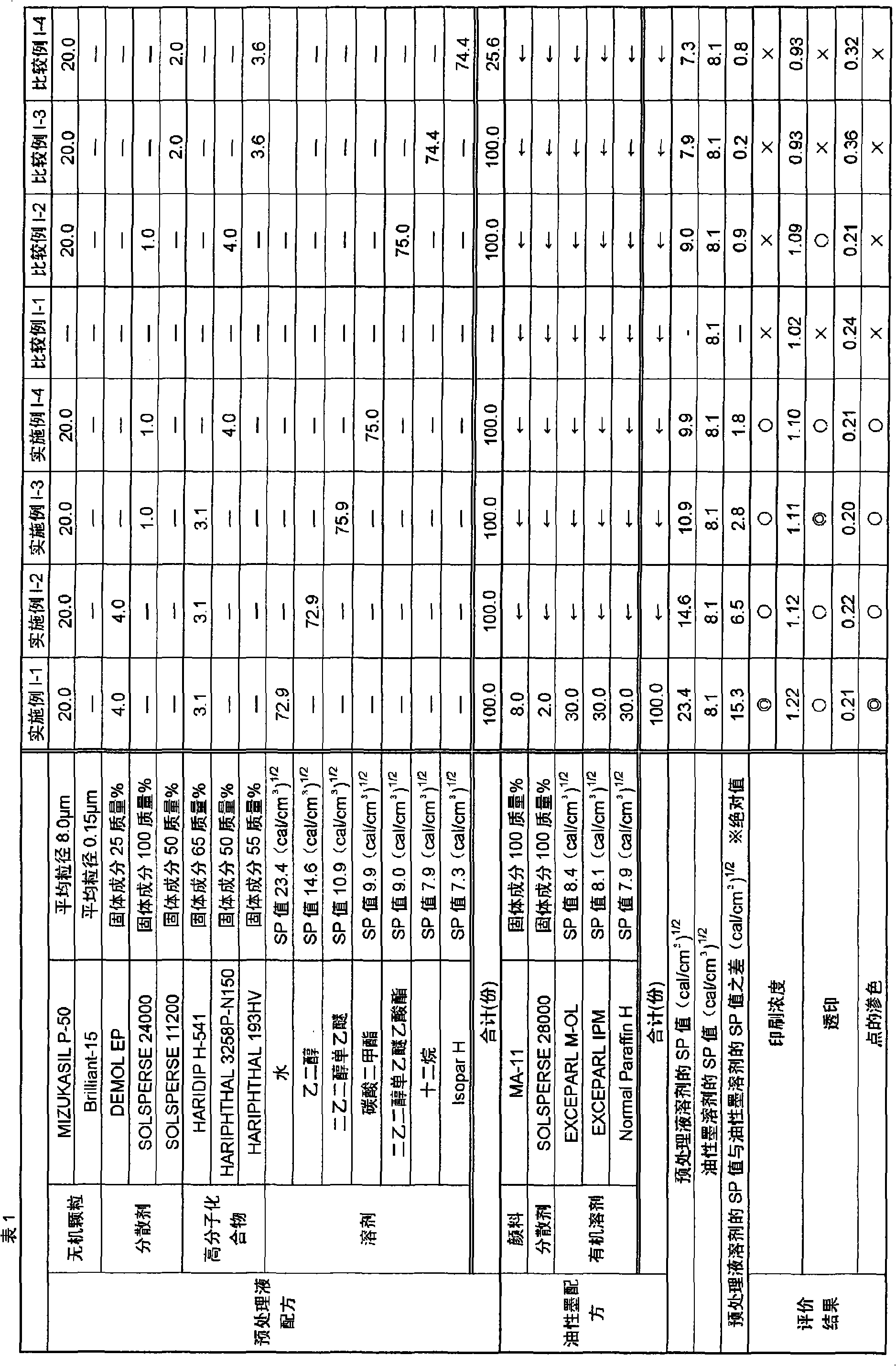

Embodiment I-1~I-4、 comparative example I-1~I-4

[0128] (1) Preparation of pretreatment liquid containing inorganic particles

[0129] The components shown in Table 1 were premixed in the ratio shown in Table 1, and then dispersed with a bead mill (using zirconia beads with a diameter (φ) of 2.0 mm), and the resulting dispersion was passed through a nylon mesh (opening diameter: 200 μm) ) to obtain the pretreatment solution.

[0130] (2) Preparation of oily ink

[0131] The components shown in Table 1 were pre-mixed in the ratio shown in Table 1, and thereafter, zirconia beads with a diameter (φ) of 0.5 mm were put into the rocking mill (ROCKING MILL) (manufactured by Seiwa Giken Co., Ltd.) Dispersion was carried out for 60 minutes, and the resulting dispersion liquid was filtered through a membrane filter (opening diameter: 3 μm) to prepare a black ink.

[0132] Table 1

[0133]

[0134] In addition, for the oil-based ink solvent as a mixed solvent of three organic solvents, its SP value (δ mix ) is calculated ...

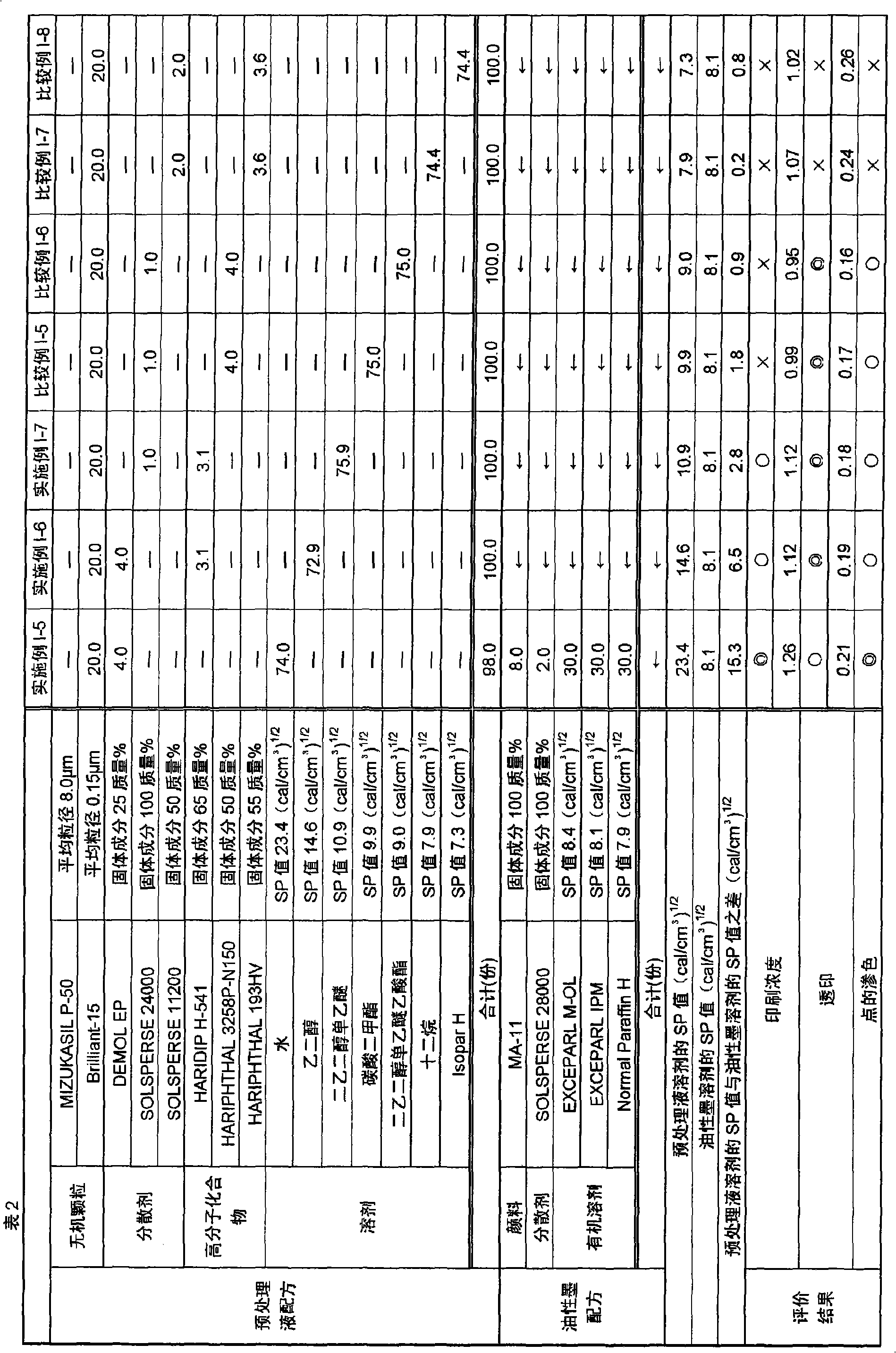

Embodiment I-5~I-7、 comparative example I-5~I-8

[0172] Except having replaced the formula of Table 1 with the formula of Table 2, it experimented similarly to Example I-1. The results are shown in Table 2.

[0173] Table 2

[0174]

[0175] However, the details of the raw materials described in Table 2 are the same as those in Table 1.

[0176] From the results in Table 2, the following facts can be seen.

[0177] In Examples I-5 to I-7 using the pretreatment liquid of the present invention, sufficient printing density was obtained while preventing offset. In contrast, the difference between the solubility parameter (SP value) of the solvent of the pretreatment liquid and the solubility parameter (SP value) of the oily ink is less than 2.0 (cal / cm 3 ) 1 / 2 In Comparative Examples I-5 to I-8, the printing density was low, and in Comparative Examples I-7 and I-8, offset and bleeding occurred.

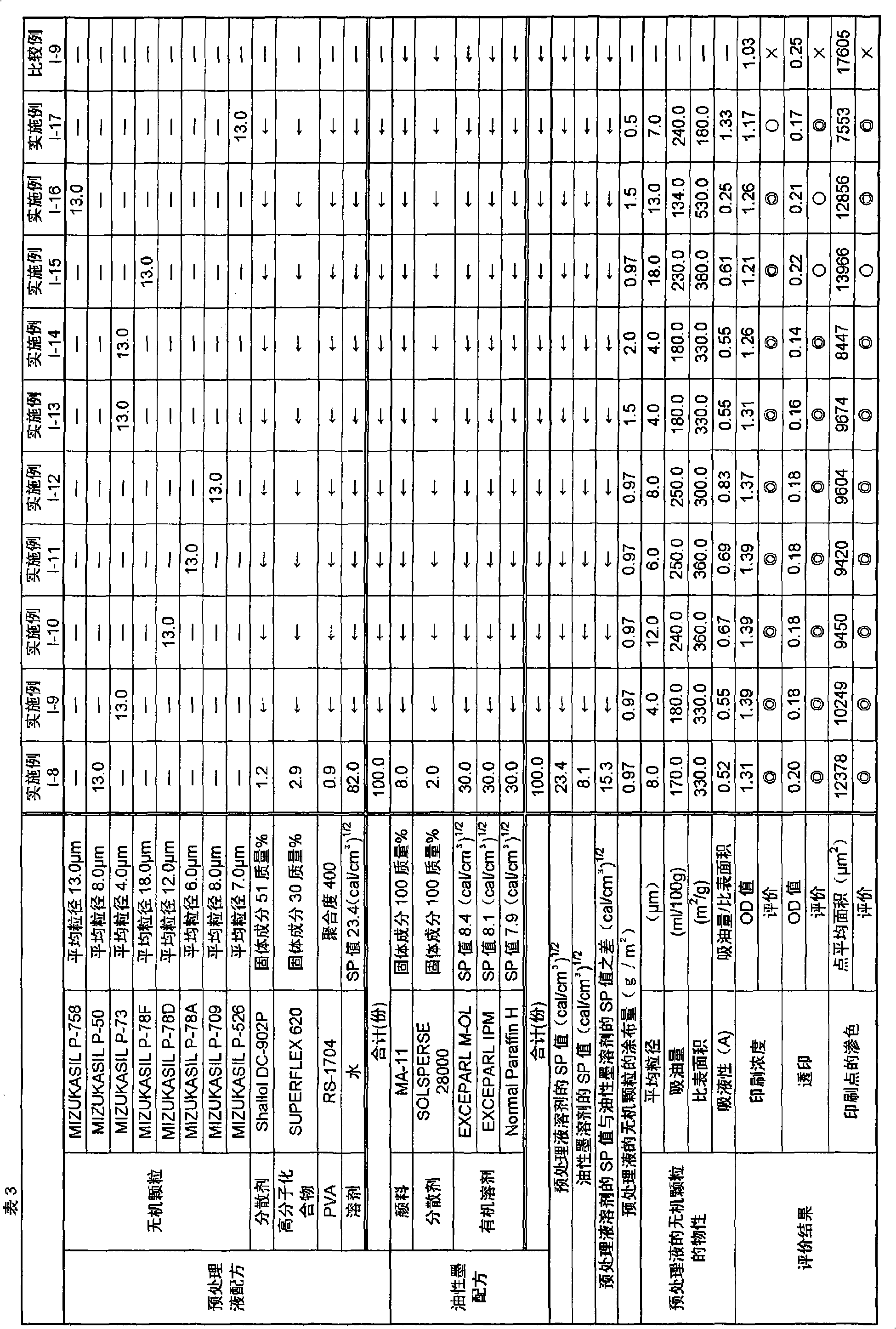

Embodiment I-8~I-17、 comparative example I-9

[0179] (1) Preparation of pretreatment liquid containing inorganic particles

[0180] The components shown in Table 3 were premixed at the ratios shown in Table 3, and then dispersed for 1 minute with an ultrasonic disperser, and the resulting dispersion was used as a pretreatment liquid.

[0181] (2) Preparation of oily ink

[0182] The components shown in Table 3 were pre-mixed at the ratio shown in Table 3, and thereafter, zirconia beads with a diameter (φ) of 0.5 mm were put into the rocking mill (ROCKING MILL) (manufactured by Seiwa Giken Co., Ltd.) Dispersion was carried out for 60 minutes, and the resulting dispersion liquid was filtered through a membrane filter (opening diameter: 3 μm) to prepare a black ink.

[0183] table 3

[0184]

[0185] In addition, for the oil-based ink solvent as a mixed solvent of three organic solvents, its SP value (δ mix ) is calculated according to the above formula (2).

[0186] However, the details of the raw materials des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap