Method for improving effective paving of propping agents in large and thick reservoir

A proppant and reservoir technology, applied in the field of improving the effective laying of proppant in the vertical direction of hydraulic fractures, can solve the problems of low propping efficiency, poor fracturing effect, unreasonable fracturing construction methods, etc., to achieve effective laying setting, improving the transformation effect, and achieving the effect of effective support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

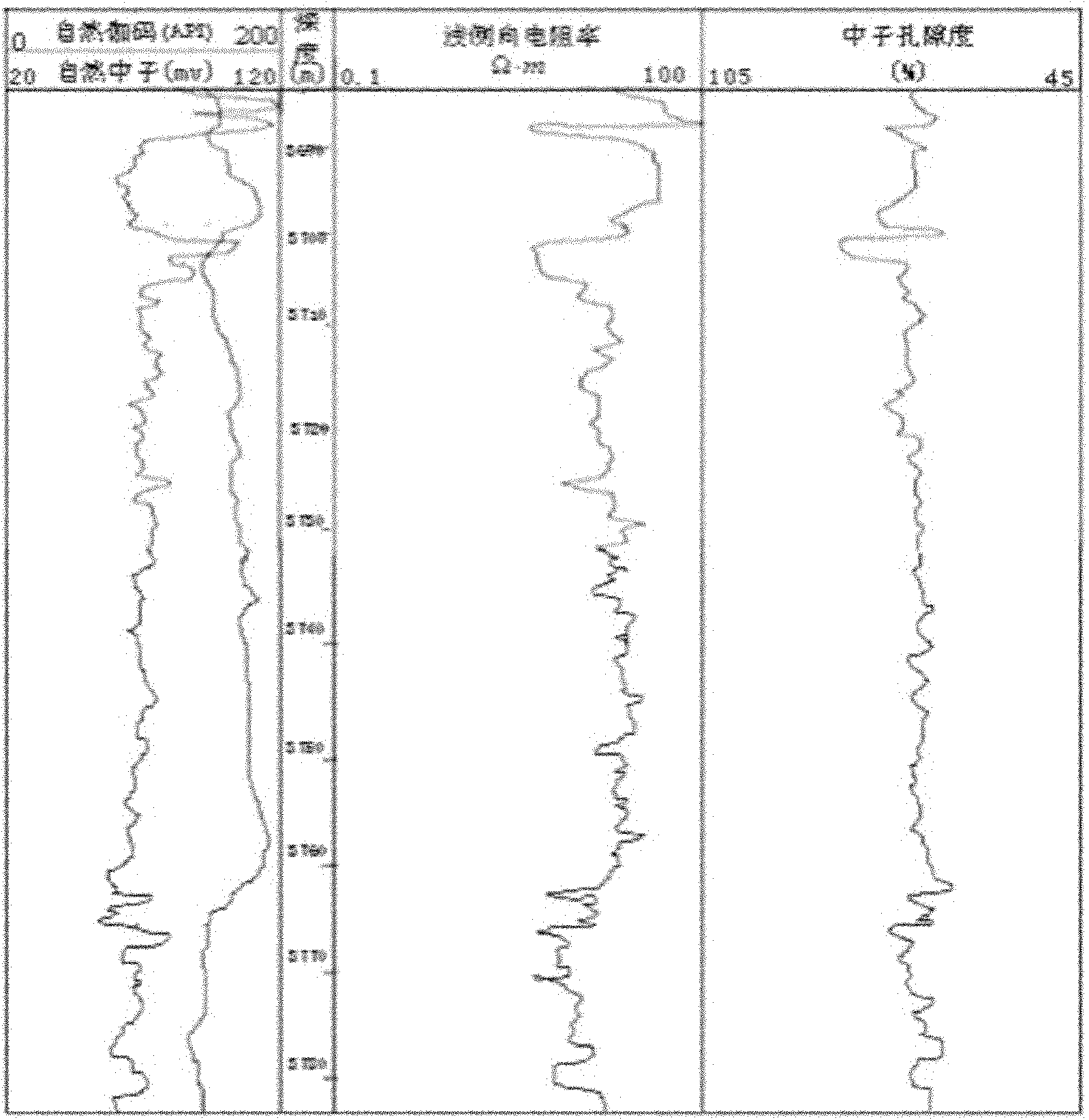

Embodiment 1

[0045]The fracturing interval of Well Yi 104-1 in Shengli Oilfield is 3698.2m to 3775.5m, and the thickness of the fracturing interval is 77.2m, which is a typical thick layer. The physical properties of the reservoir in the fracturing and fracturing section of the well are relatively uniform, and concentrated perforation is carried out at 3715m to 3735m near the middle and upper part of the thick reservoir. Fracturing adopts sanding technology with different density proppant combinations, high density: medium density: low density ceramsite proppant according to the ratio of 1.5:1:1, high density (1810kg / m 3 ) Ceramsite 48m 3 ; Medium density (1650kg / m 3 ) Ceramsite 32m 3 ; Low density (1470kg / m 3 ) Ceramsite 32m 3 In the process of fracturing, the way of adding sand in the fracturing process is to first pump high-density ceramsite, then pump medium-density ceramsite, and finally pump low-density ceramsite to add ceramsite proppant in order to effectively support all fract...

Embodiment 2

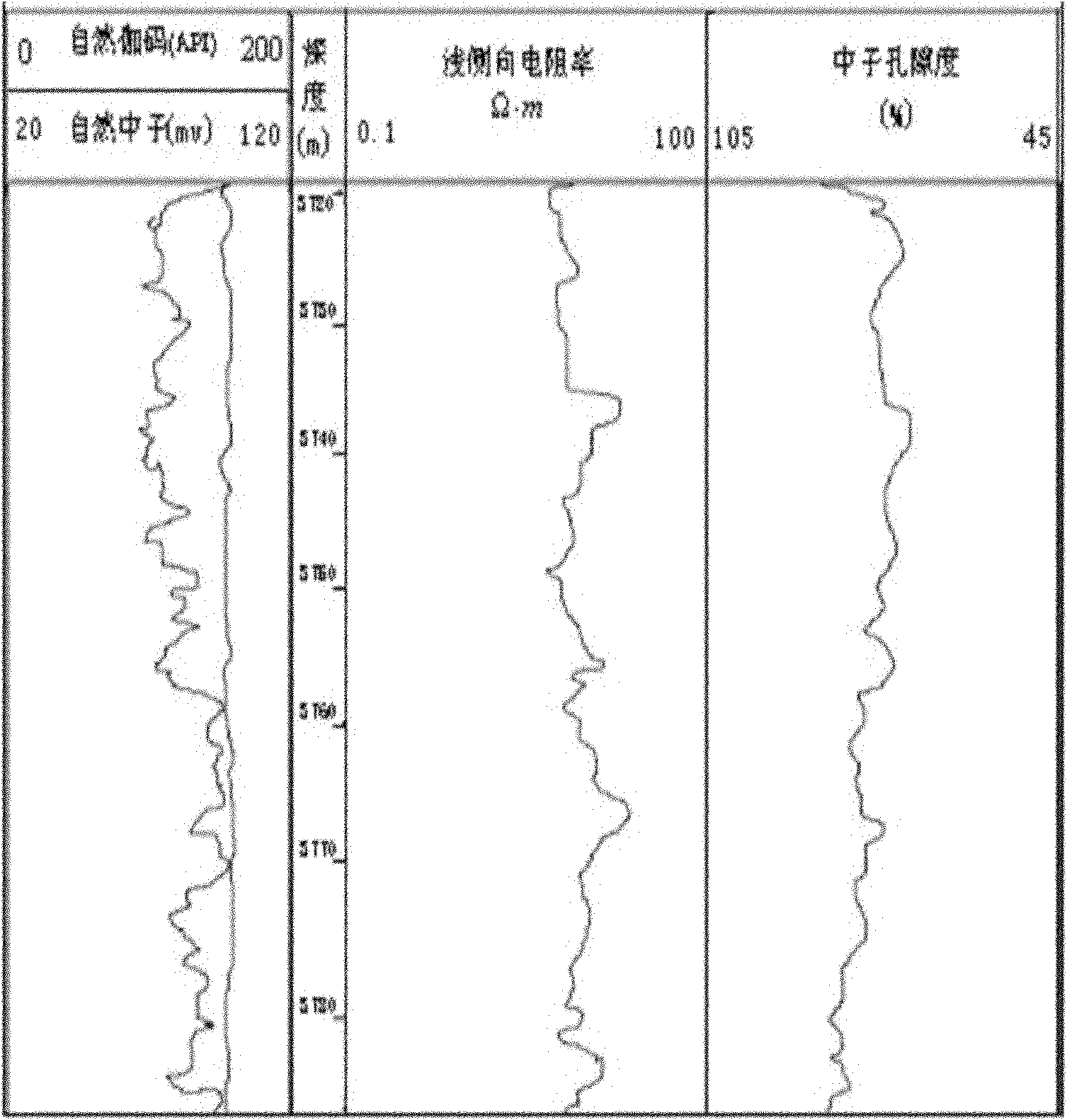

[0047] The fracturing interval of Well Yi 104-6 in Shengli Oilfield is 3724m-3785.5m, and the thickness of the fracturing interval is 61.5m, which is a typical thick reservoir. The upper No. 3 sub-layer (3727m-3760m) and the lower No. 5 sub-layer (3762m-3783.5m) of the fracturing section have good physical properties. Concentrated perforation is used for these two sub-layers respectively, and the perforated section is No. 3 The middle and upper part of the reservoir is 3731m-3744m and the middle and upper part of No. 5 reservoir is 3762m-3770m. The fracturing adopts sand adding technology with different density proppant combination, high density and low density ceramsite proppant according to the ratio of 2.7:1, high density (density 1810kg / m 3 ) Ceramsite 128m 3 and low density (1470kg / m 3 ) Ceramsite 48m 3 , the way of adding sand during the fracturing process is to add ceramsite proppant in the order of pumping high-density ceramsite first, and finally pumping low-densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com