Method for calibrating high pressure equipment

A technology of high-pressure equipment and verification device, applied in the direction of measuring fluid pressure, measuring device, instrument, etc., can solve the problems of pollution, not easy to clean, waste of cost and time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

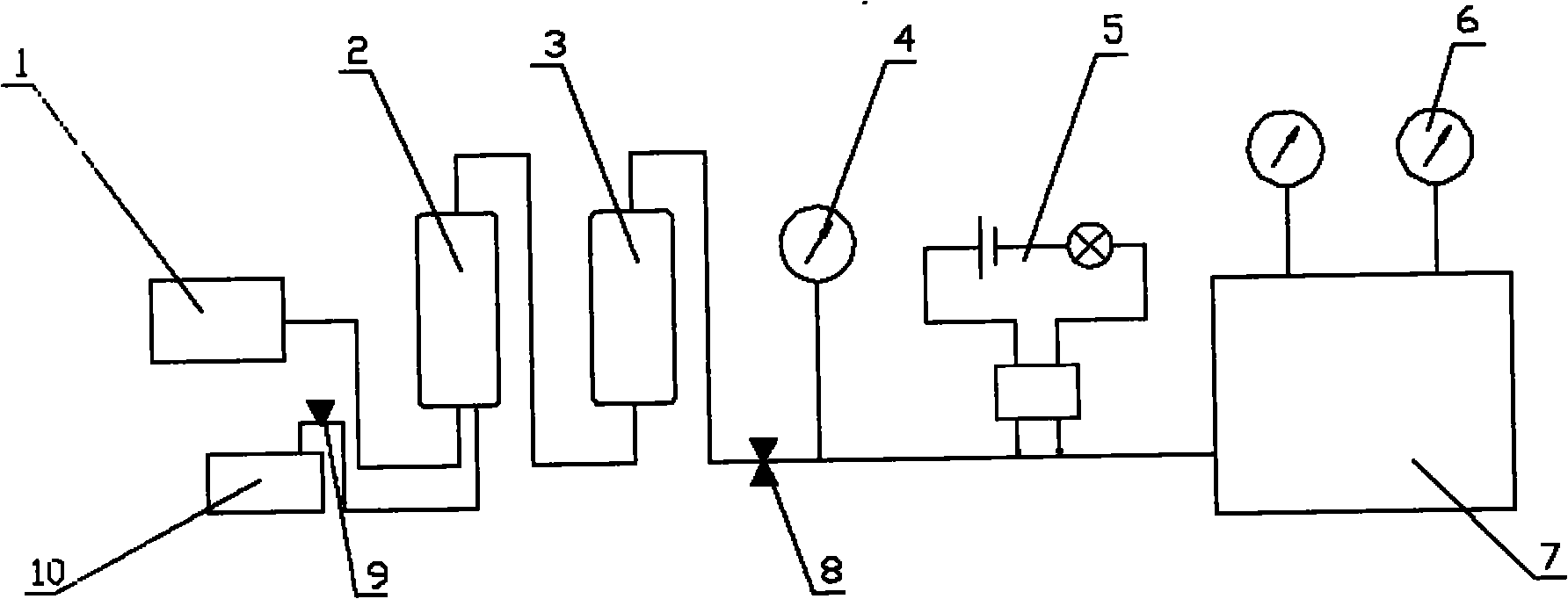

[0019] A verification method for high-pressure equipment, which uses a special pressure gauge verification device to verify the high-pressure equipment, includes two detection steps:

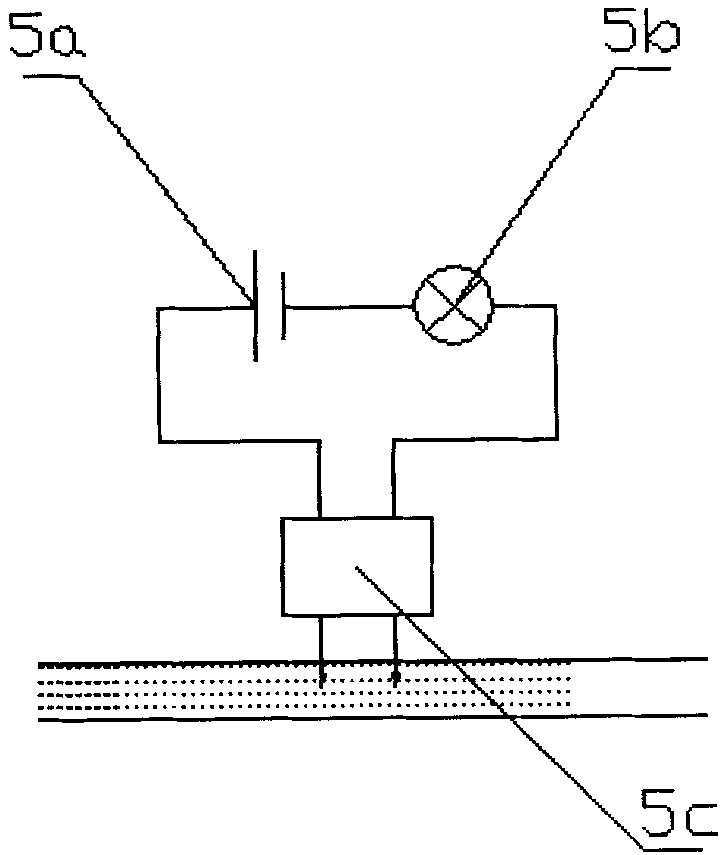

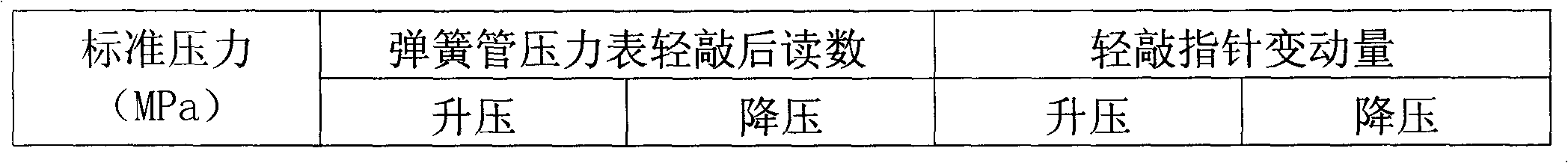

[0020] i. Verification of the pressure gauge; close the valve I 9, open the valve II8, use the pressure hand pump to suck water from the water storage tank, and press it into the pressure pump 1 of the verification device through the high pressure hose, so that the spring tube pressure gauge on the high pressure equipment 7 6 Display a certain value, compare the 6 part of the spring tube pressure gauge of the high pressure device 7 by observing the difference between the readings of the standard pressure gauge 4 and the spring tube pressure gauge 6 on the high pressure device 7, and then adjust the adjustment and adjustment on the pressure pump 1. Fine-tuning the knob to realize the metrological verification of the spring tube pressure gauge 6 of the high-pressure equipment 7;

[0021] ii. Air t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap