Detection method of corrugated plate

A detection method and corrugated plate technology, which are applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of unreliable coil fixation, reworked coil anti-corona layer, etc., to ensure the service life, Guarantee the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

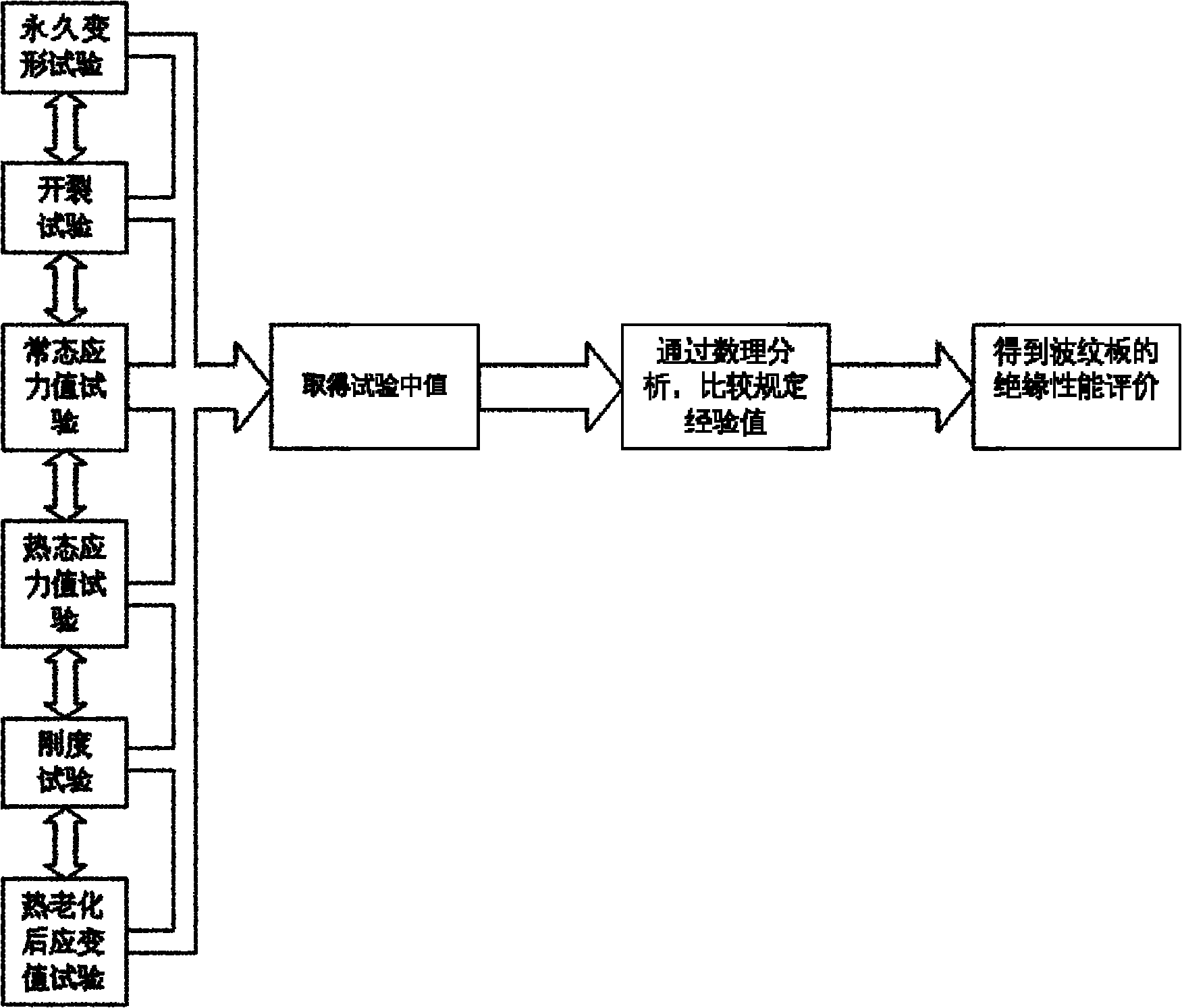

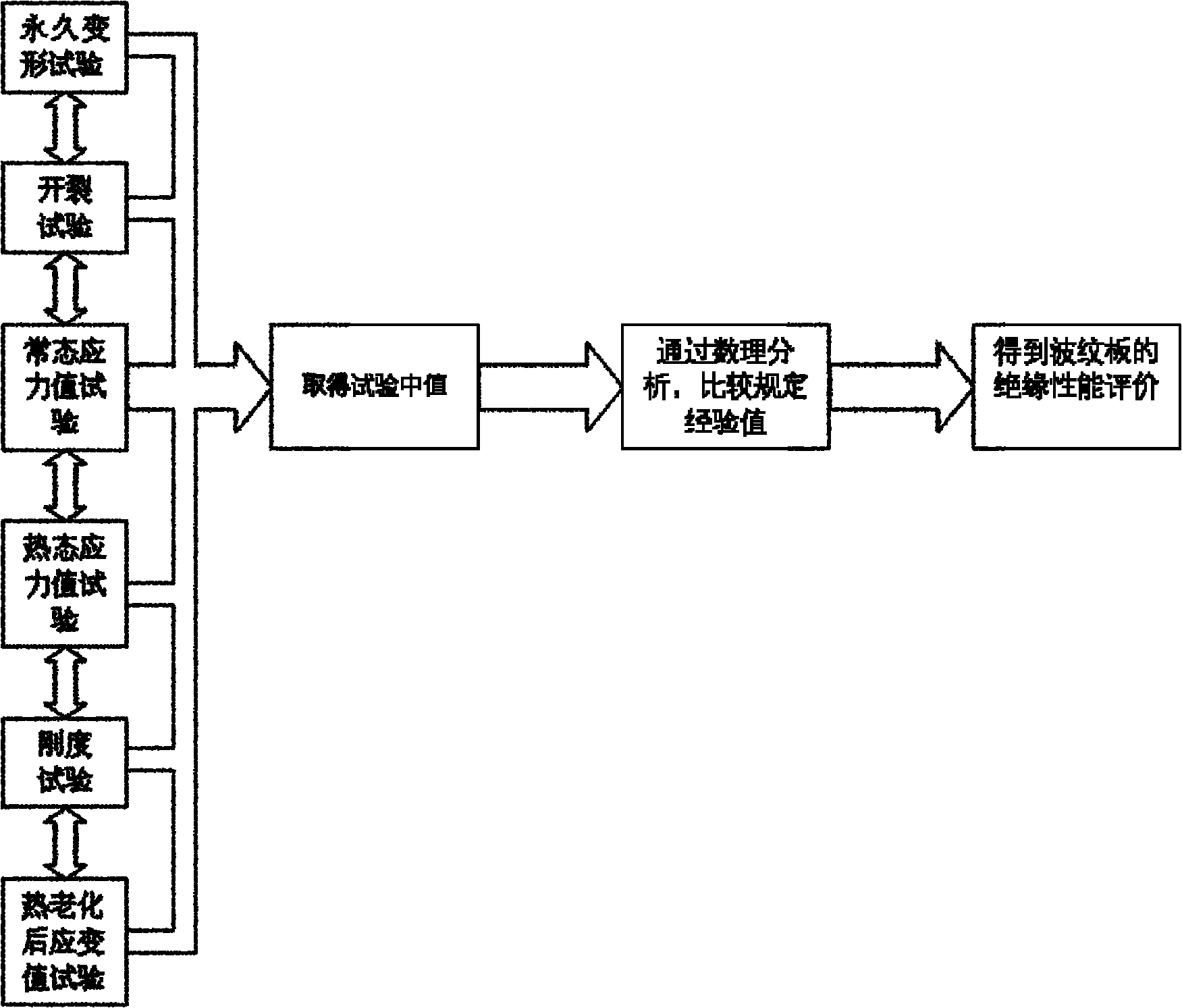

[0008] Such as figure 1 The present invention shown is a corrugated plate detection method, which is divided into five steps: A: permanent deformation test: according to the measured thickness of the sample corrugated plate, select the corrugated plate test on the two corrugated plates with the largest and smallest thickness. Take two pieces of corrugated plate samples. The size of the corrugated plate sample is (50±1)×(195±5) (mm). Each piece of corrugated plate sample should have five complete wave peaks. Or cutting beyond 5mm before the trough. When cutting the sample with a grinding wheel, the grinding wheel should be cooled with water, and the corrugated plate sample should be placed in an oven at 105±3°C for 24 hours, and then cooled to room temperature in a desiccator; Table test method, measure the peak value of the sample, take five peak points for each piece and mark them, the measurement accuracy is 0.01mm, put the corrugated plate sample between two flat plates, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com