Elevator car lighting device

A lighting device and car technology, which is applied to elevators, transportation and packaging in buildings, can solve problems such as dirt, and achieve the effects of reducing pressure, reducing the size of the protrusion, and reducing the frequency of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0028] Refer below Figure 1 to Figure 4 The car lighting device of the first embodiment will be described.

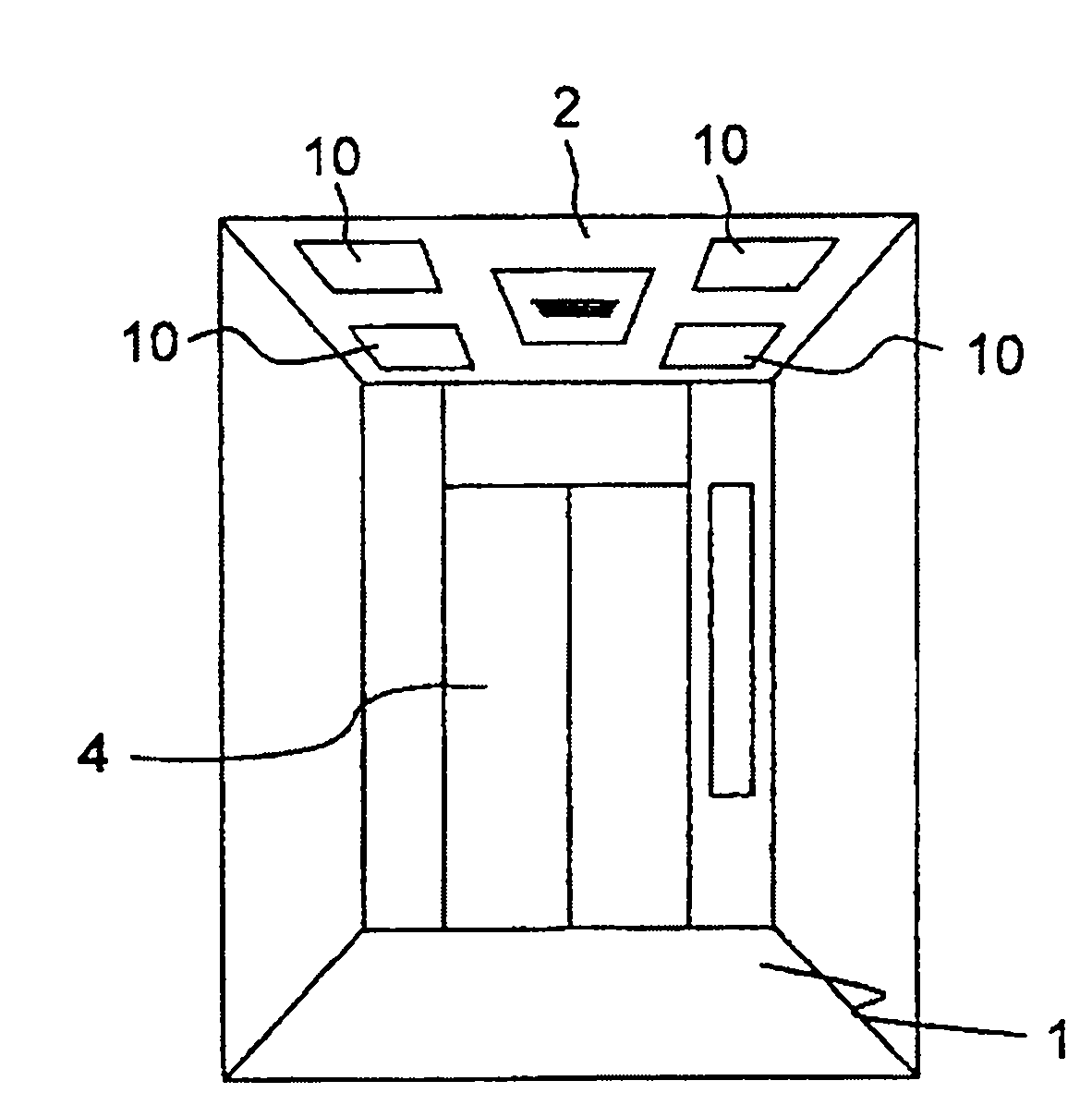

[0029] Such as figure 1 As shown, the roof of the car 1 of the elevator is formed by a ceiling 2 . Four car lighting devices 10 of the first embodiment are provided on the ceiling 2 . figure 1 4 in is the car door.

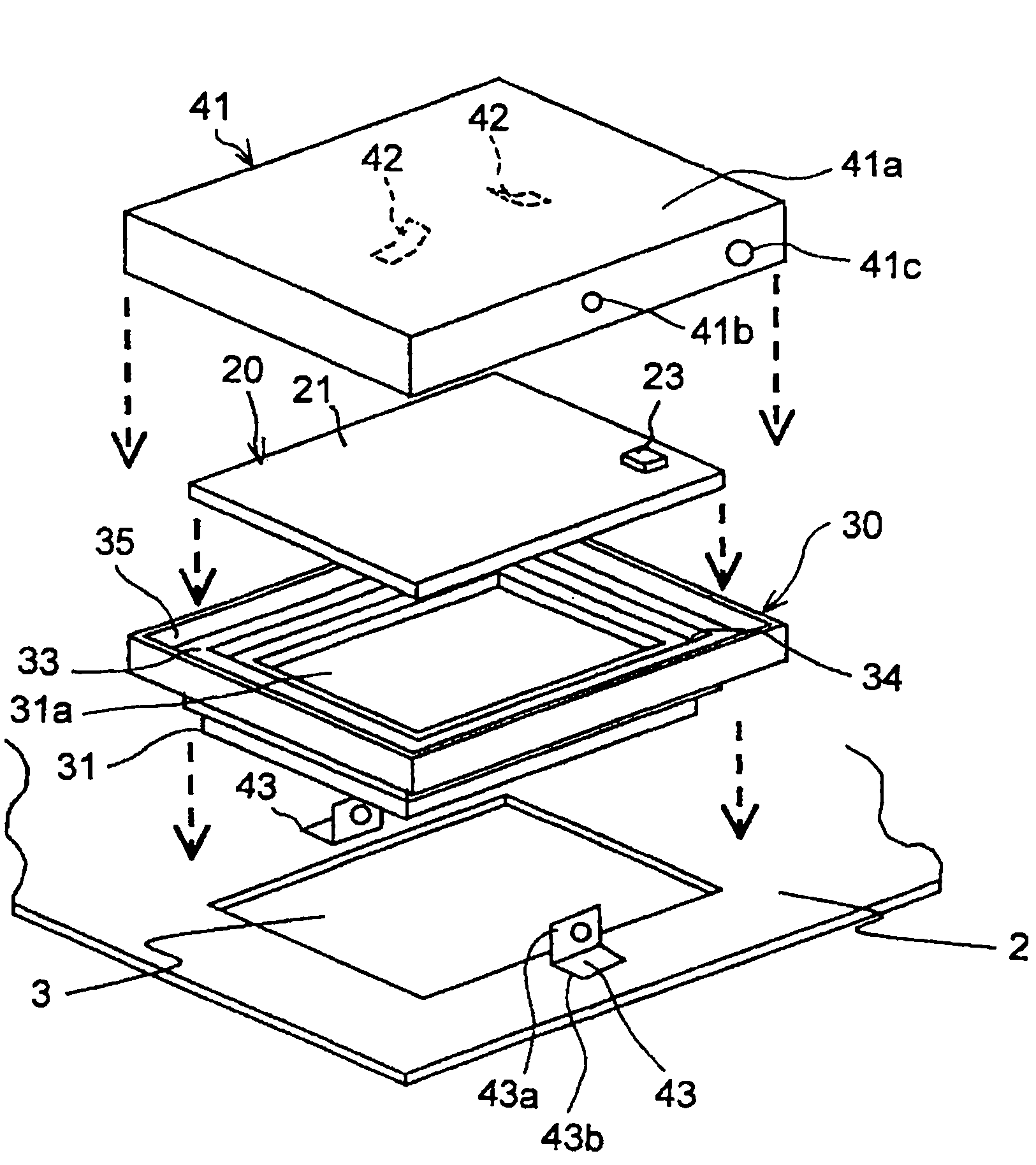

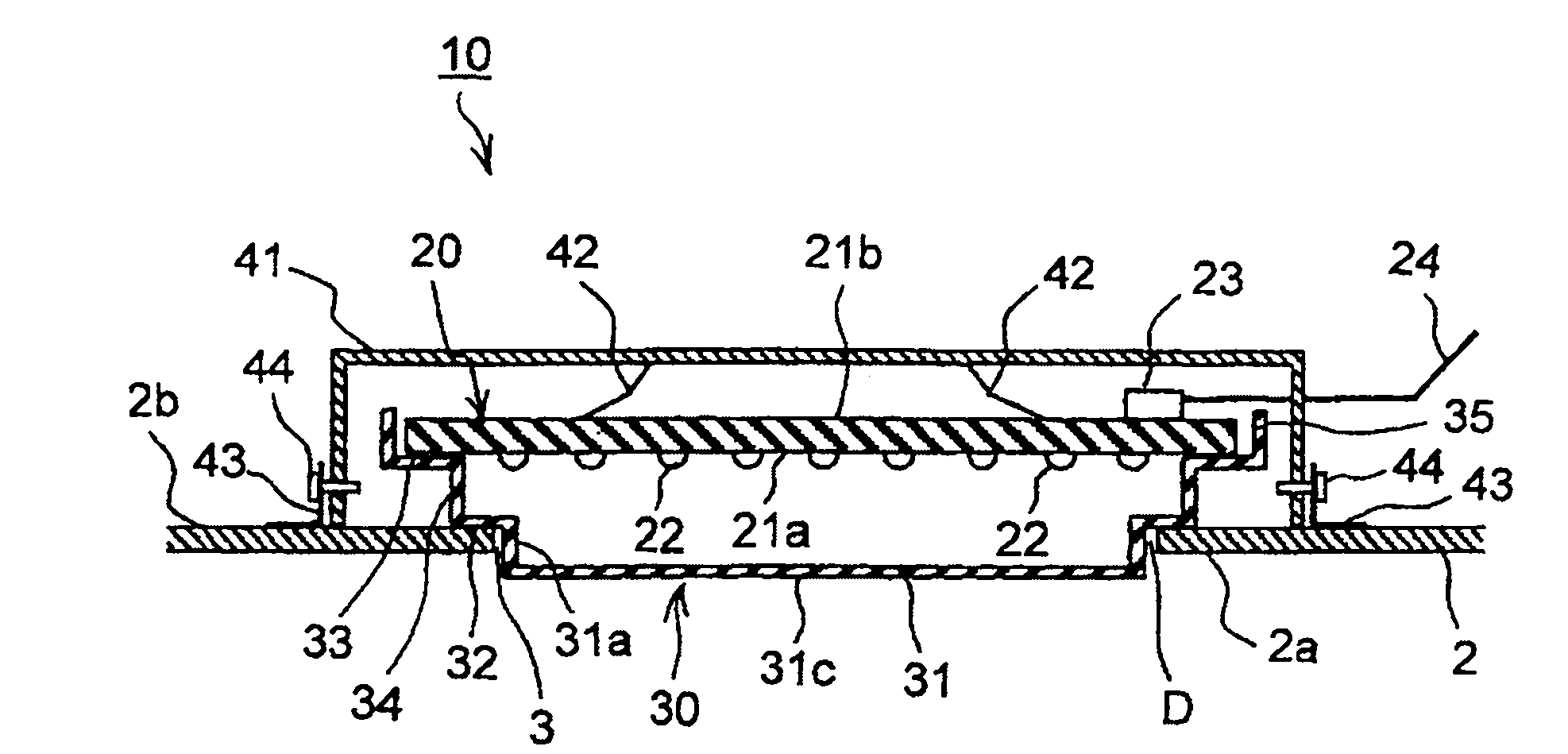

[0030] Such as figure 2 , image 3 As shown, the car lighting device 10 includes: a ceiling 2 forming the ceiling of the car 1; LED22 as a light-emitting element (refer to image 3 ) light emitting board 20;

[0031] The light-emitting panel 20 has a substrate 21 that is a rectangular plate member that is deployed along a direction substantially parallel to the direction in which the ceiling 2 is deployed. A plurality of LEDs 22 are arranged on the lower surface 21a (the surface on the car 1 side) of the substrate 21 . The intervals between adjacent LEDs 22 are constant, and they are evenly distributed in dots over substantially the entire surfa...

no. 2 approach

[0055] Refer below Image 6 A car lighting device according to a second embodiment will be described.

[0056] Such as Image 6 As shown, the car lighting device 200 of the second embodiment has a light-transmitting plate 201 having a shape different from that of the light-transmitting plate 30 of the first embodiment. The surface emission performance of the transparent plate 201 is the same as that of the transparent plate 30 . The structure of the car lighting device 200 other than the light-transmitting plate 201 is the same as that of the car lighting device 10 .

[0057] The light-transmitting plate 201 of the car lighting device 200 does not have the partition part 34 like the light-transmitting plate 30 of the car lighting device 10 . In addition, the plate thickness of the light-transmitting plate 201 can be regarded as having the function of the spacer, but in the second embodiment, the function of the spacer due to the plate thickness is not substantial, so in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com