Method for laying pulp pipelines in marsh district

A pipeline and swamp technology, applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of high fuel filling risk, long pipeline laying period, high construction cost, and achieve simple and fast laying process. , The laying process saves time and effort, and has the effect of high freedom of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in combination with specific embodiments.

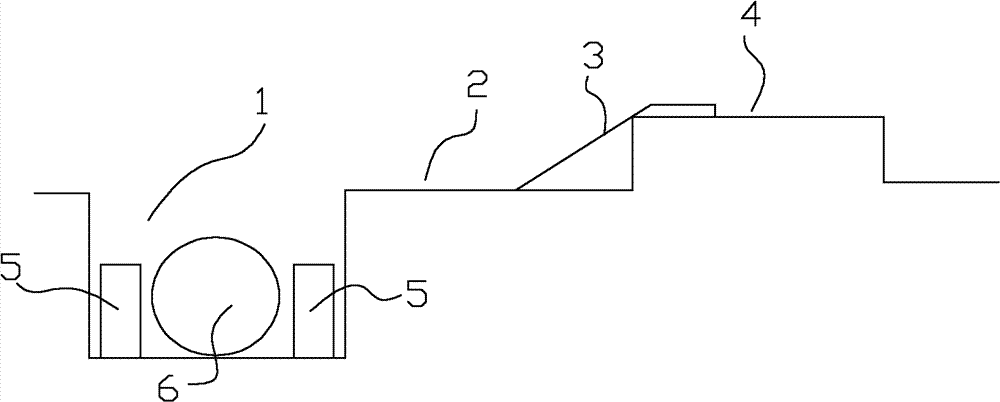

[0022] Such as figure 1 Shown, the laying method of the slurry pipeline of the present invention in the marsh section may further comprise the steps:

[0023] A. Excavate the pipe ditch 1 in the marsh area, set the pipeline floating area 2 and the pipeline assembly area 4 in the area outside the pipe ditch 1, the altitude of the pipeline assembly area 4 is higher than the pipeline floating area 2;

[0024] B. Inject water into the pipeline floating area 2 and the pipe ditch 1;

[0025] C. Floating on the water surface of the pipeline floating zone 2 after assembling N pipelines into a pipeline 6 in the pipeline assembly area;

[0026] D. Float the pipeline 6 in step C from the pipeline floating area 2 into the predetermined installation position in the trench 1 , and then sink the pipeline 6 into the bottom of the trench 1 .

[0027] Such as figure 1 As shown, the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com