Charger with automatic power-off function

An automatic power-off and charger technology, which is applied in current collectors, non-polar relays, battery circuit devices, etc., can solve the problems of battery failure and delay in charging time, and achieve the effects of simple structure, avoiding waste, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

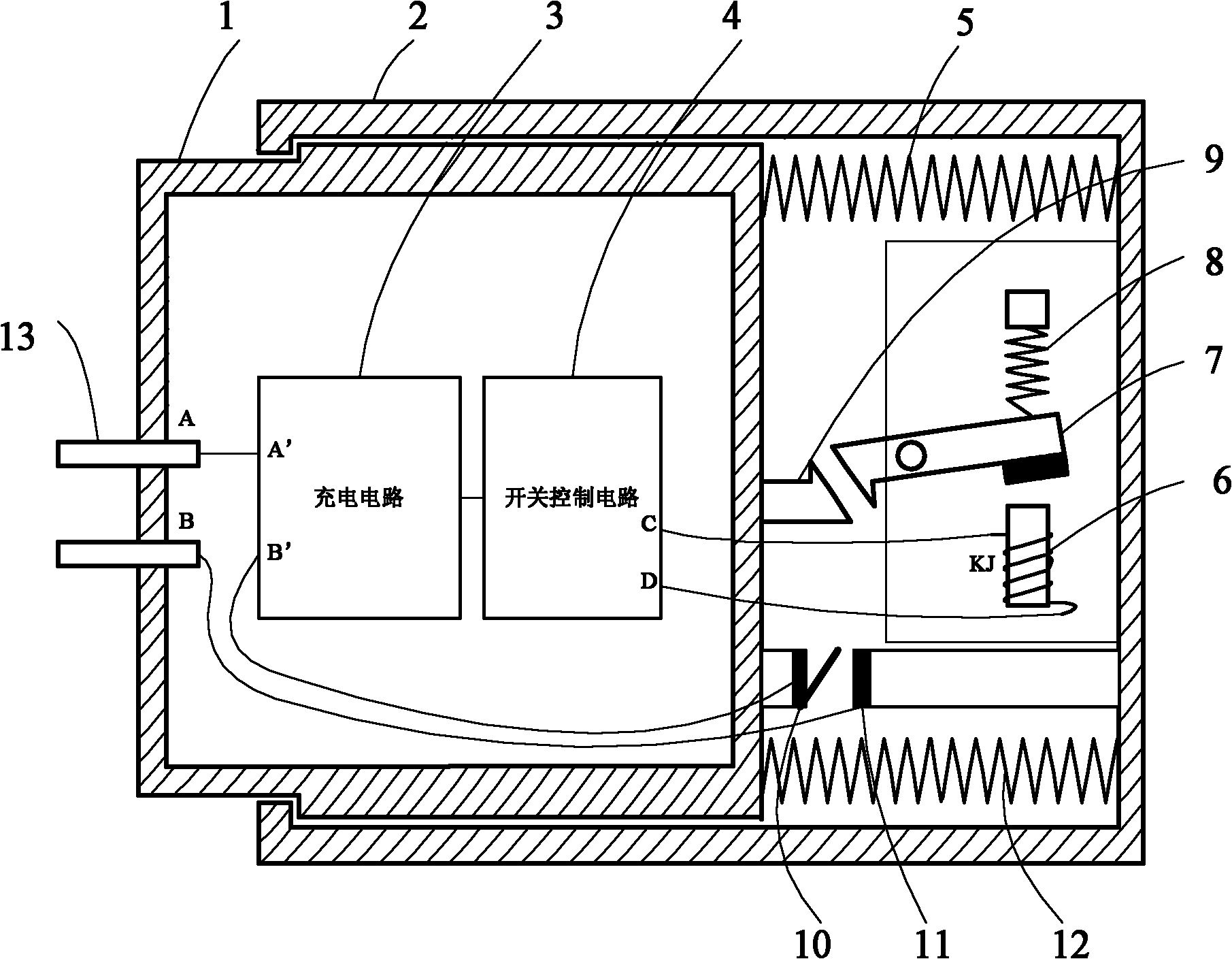

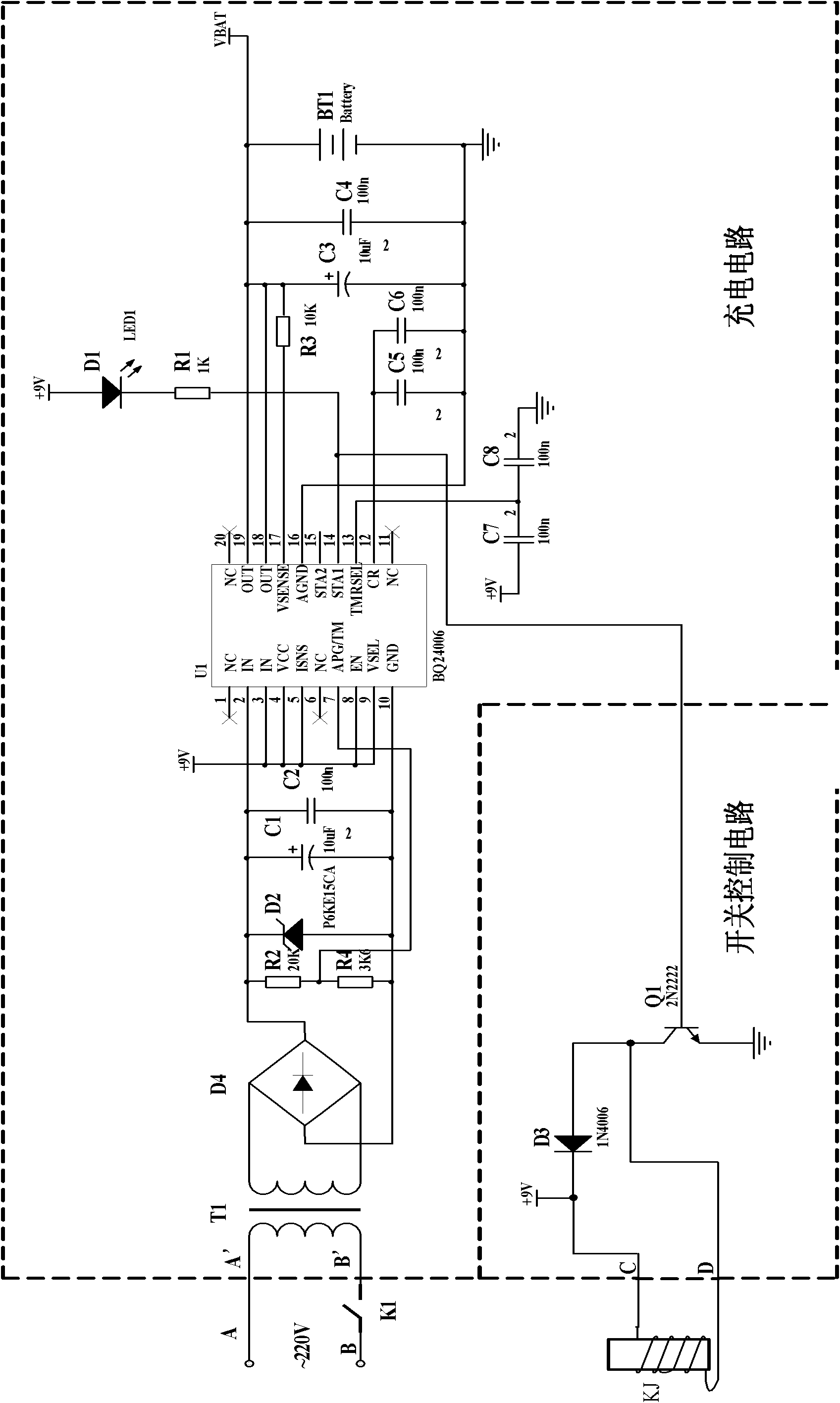

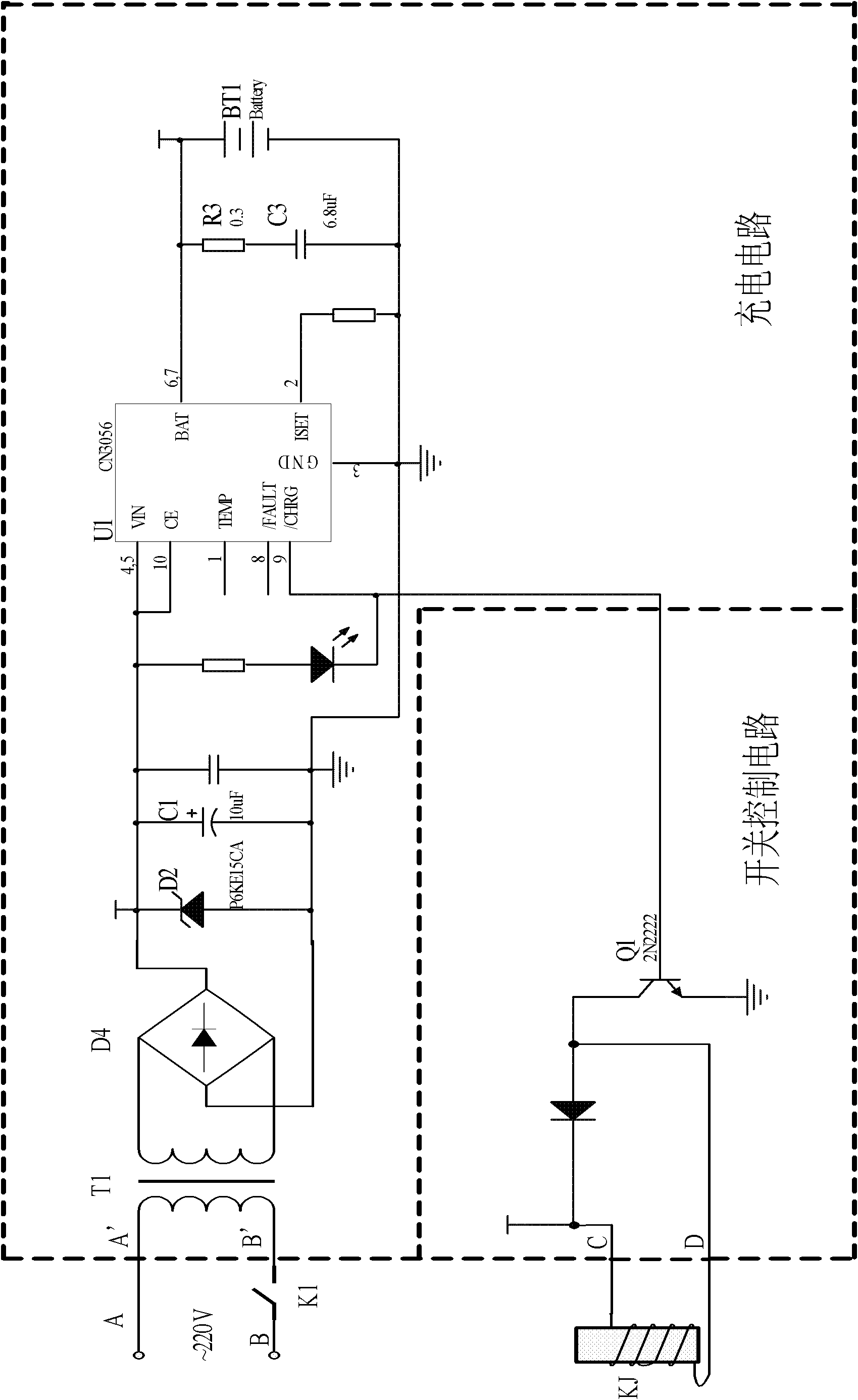

[0012] Such as figure 1 As shown, the charger with automatic power-off function of the present invention includes an inner casing 1, a plug 13, a charging circuit 3, a switch control circuit 4, an inner casing stop hook 9, a metal spring piece 10, an outer casing 2, and a pressure spring 5, 12, electromagnet 6, outer shell stop hook 7, tension spring 8, metal contact 11; plug 13 is fixed on inner shell 1; inner shell 1 and outer shell 2 are connected by compression spring 5, 12 ; The inner casing stop hook 9 and the metal spring piece 10 are fixed on the inner casing 1; the outer casing stop hook 7 is installed in the outer casing 2 through the rotating shaft 14, and the front end with the hook is in line with the position of the inner casing stop hook 9 Correspondingly, the end of the housing body stop hook 7 is connected to the housing body 2 through a tension spring 8; When the coil KJ is energized, the electromagnet 6 generates a magnetic force, and under the action of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap