Clamp and process for machining welding yoke of automobile

A processing technology and welding fork technology, which is applied in the field of automobile welding fork processing fixtures and processes, can solve the problems of difficult and high precision in ordinary processing technology, and achieve the effect of high precision and satisfying high precision and high quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

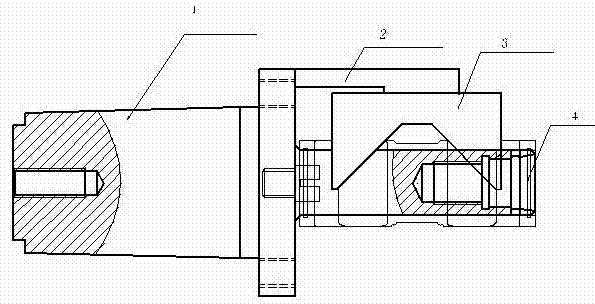

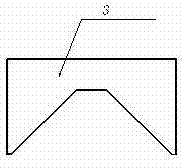

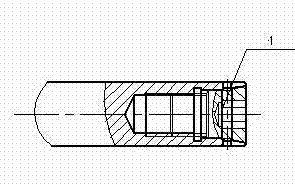

[0014] figure 1 , figure 2 with image 3 The reference numbers shown are as follows: mandrel 1 , transition plate 2 , concentric positioning plate 3 , mandrel rod 4 .

[0015] figure 1 , figure 2 with image 3 In the schematic diagram of a processing fixture for an automobile welding fork shown, it is composed of a mandrel 1, a transition plate 2, a concentric positioning plate 3 and a mandrel rod 4, and a transition plate 2 is provided on the top of the mandrel 1, and the transition plate 2 is connected to the concentric The positioning 3 plates are connected, and the mandrel rod 4 is connected with the mandrel 1 .

[0016] An automobile welding fork processing technology, the two concentric holes of the welding fork are set on the mandrel, and the outer diameter of the upper end of the welding fork is leaned against the V-shaped surface of the positioning plate. This position is the radial center of the workpiece, and then through the mandrel The front end clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com