Material distributor for packing machine

A material distributing device and packaging machine technology, applied in packaging, etc., can solve the problems of affecting packaging efficiency, affecting production efficiency, food mess, etc., and achieve the effect of facilitating the packaging process, improving production efficiency, and ordering the food array

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

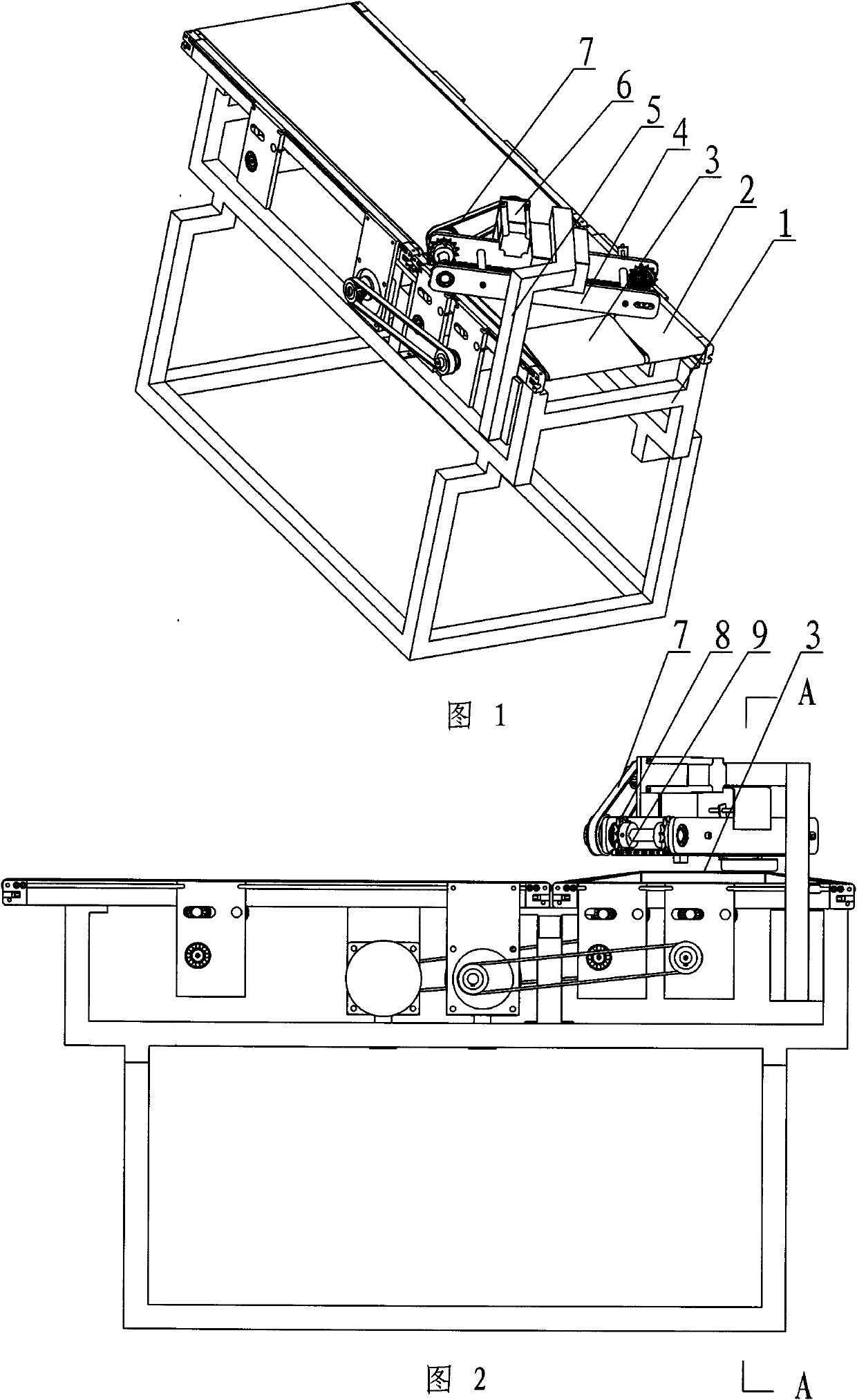

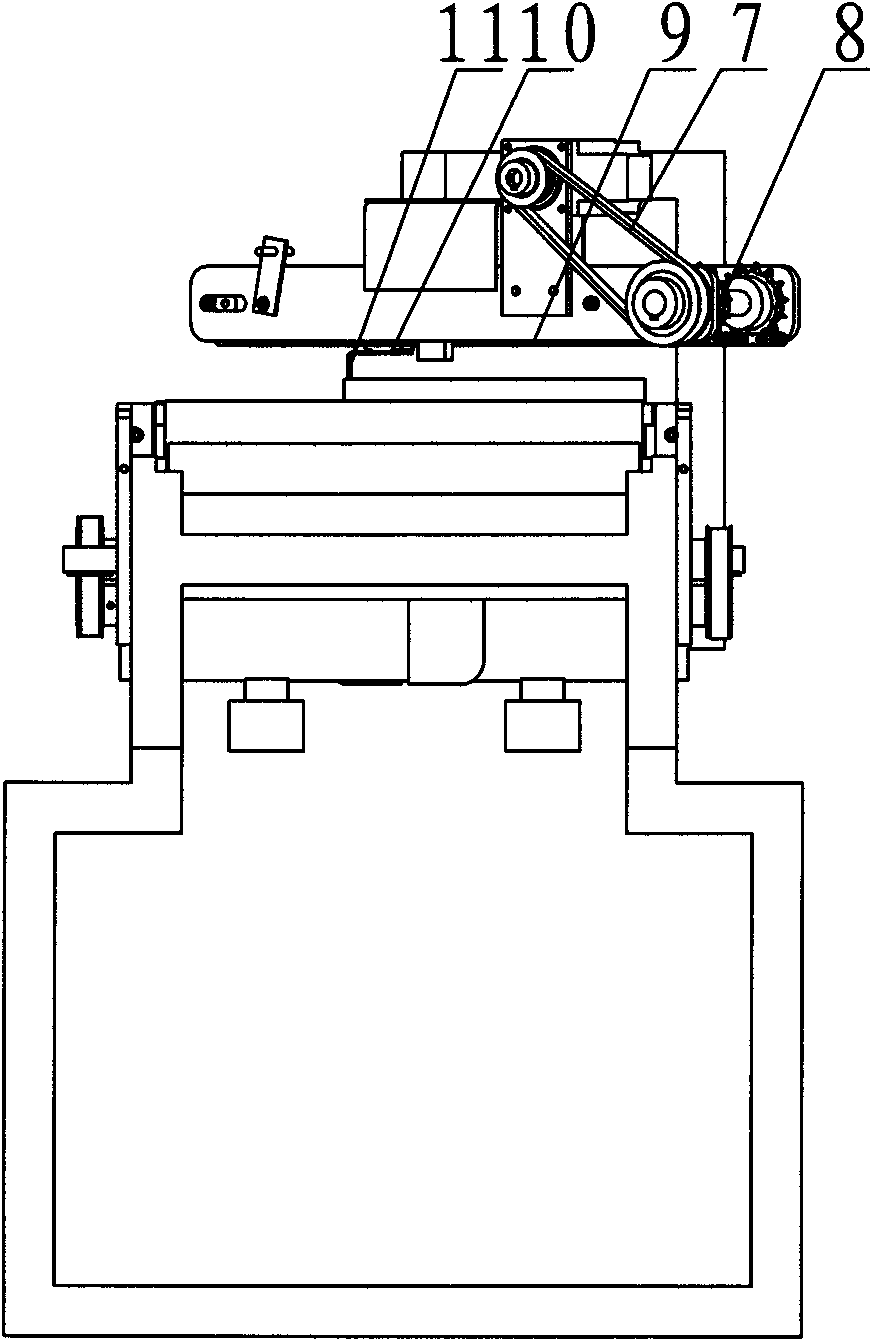

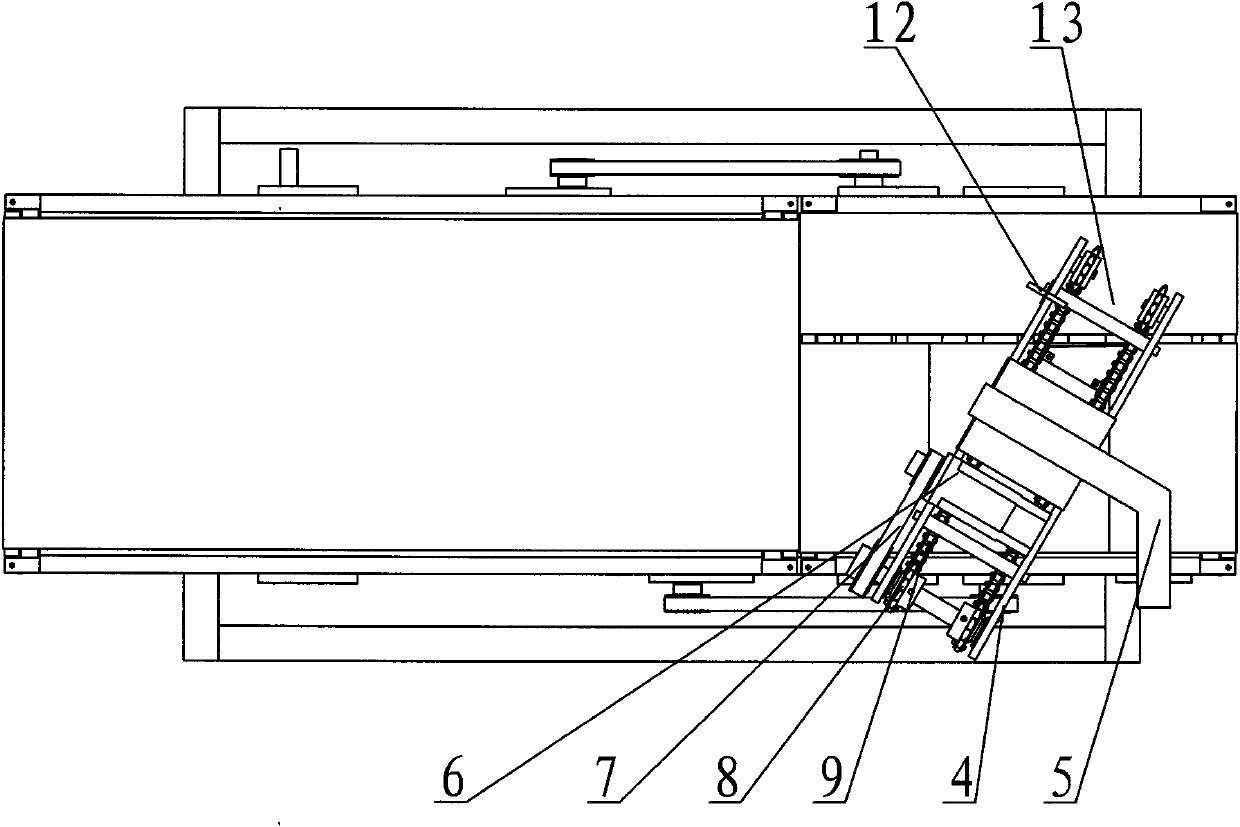

[0007] Refer to attached Figure 1-8 , the left side mentioned in the present invention is for figure 1 In terms of the direction of the drawing. The distributing device of this packaging machine includes a body 1, a conveyor belt and a mounting frame 4, the conveyor belt is installed on the body 1, and is used to move the packaged objects placed thereon, and the mounting frame 4 passes through A frame body 5 is installed on the body 1, and forms a gap that can pass through the food with the conveyor belt. The mounting frame 4 is provided with a motor 6, a chain 9 and a sprocket 8, and the chain 9 is coated on the On the sprocket 8, the sprocket 8 is connected with the rotating shaft of the motor 6 by the belt 7, so that the transmission relationship between the motor 6 and the chain 9 is formed, and the pushing plate 14 is installed on the chain 9, The axial center line of the mounting frame 4 forms an included angle with the axis of the conveyor belt, and the pushing plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com