Anti-overlapping and well-organized accumulation and transportation device and method of liquid flexible packaging bags

A technology of flexible packaging bags and accumulative conveying, which is applied in the directions of packaging, conveyor objects, transportation and packaging, etc. It can solve the problems of increasing labor intensity, large manpower, and reducing production efficiency, so as to improve production efficiency, prevent overlapping, and device structure Set reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

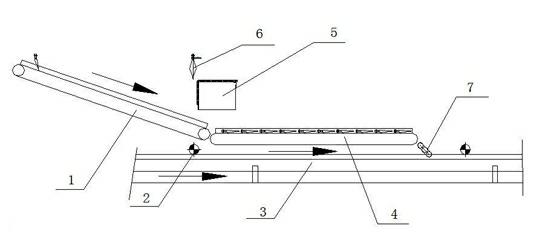

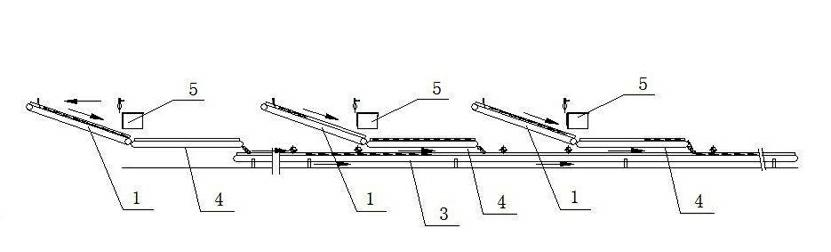

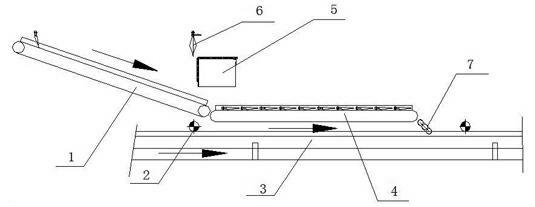

[0020] Example 1. refer to Figure 1-2 . An anti-stacking and orderly accumulation conveying device for liquid flexible packaging bags, including a main horizontal conveyor 3 located below the filling machine 5 and its bag taking mechanism, below each filling machine 5 and above the main horizontal conveyor 3 All are provided with accumulation conveyor; Described accumulation conveyor is made of inclined conveyor 1 and short horizontal conveyor 4; The included angle that forms between inclined conveyor 1 and short horizontal conveyor 4 is an obtuse angle; Described Inclined conveyor 1 and short horizontal conveyor 4 are driven by stepping motors, and the stepping motors are connected to the control computer, and the start, stop and step length of the stepping motors are controlled by the control computer; the side of the main horizontal conveyor 3 is provided with several Signal Sensor 2.

Embodiment 2

[0021] Example 2. In the anti-stacking and orderly accumulation conveying device for liquid flexible packaging bags described in Embodiment 1: a signal sensor 2 is also provided on the side of the inclined conveyor 1 and the short horizontal conveyor 4, and the signal sensor 2 is connected to the control computer.

Embodiment 3

[0022] Example 3. In the anti-overlapping and orderly accumulation conveying device for liquid flexible packaging bags described in Embodiment 1 or 2: the signal sensors 2 provided on the side of the main horizontal conveyor 3 are arranged in pairs and used in conjunction; each pair of signal sensors 2 , one is at the front side of the short horizontal conveyor 4, and the other is at the rear side of the short horizontal conveyor 4, and the setting distance of each pair of signal sensors 2 is adapted to the length of a group of liquid flexible packaging bags conveyed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com