Measuring method of loading quality of hoisting machine

A technology of hoisting machinery and measurement methods, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of unscientific measurement principles, narrow application range, safety hazard installation, etc., and achieve scientific and reliable calculation principles and wide application range , the effect of protecting the safety of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

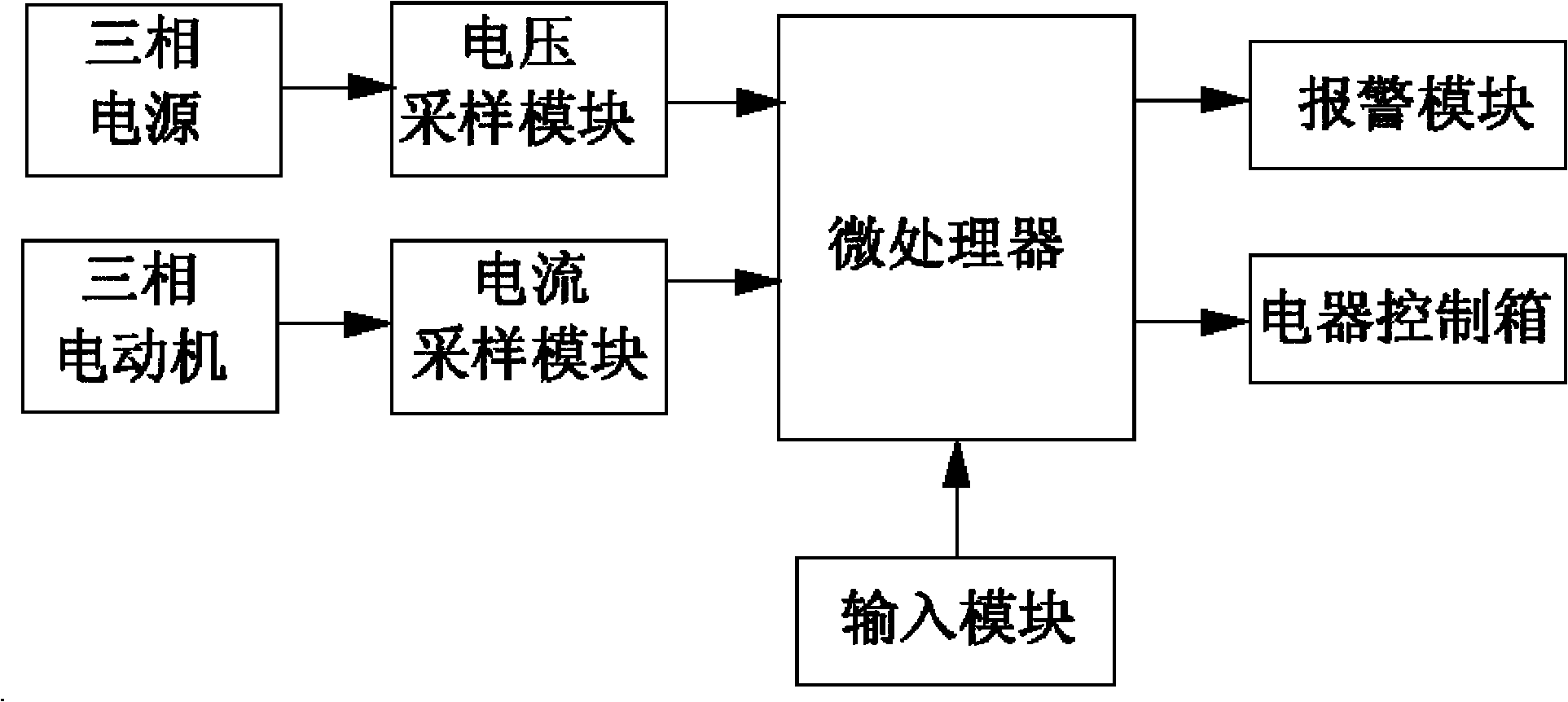

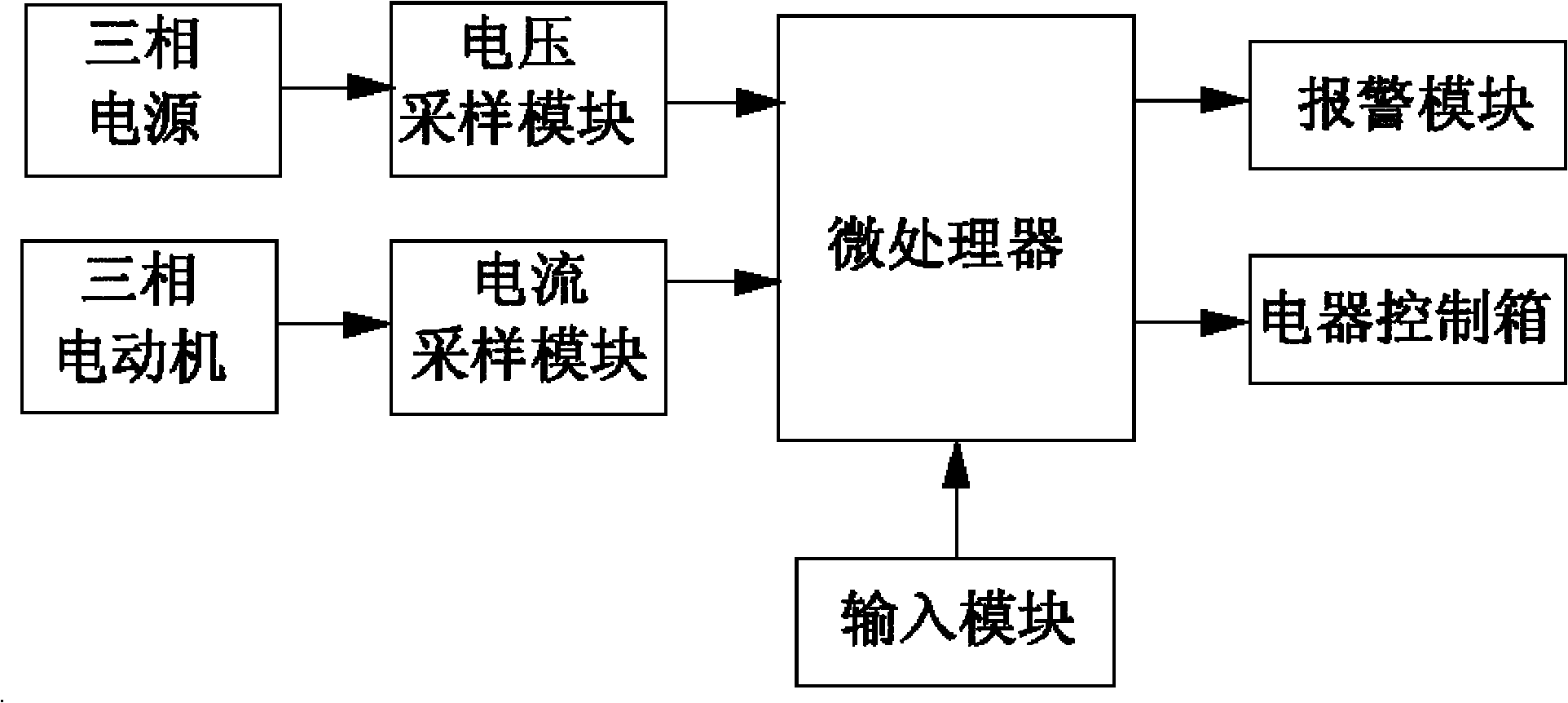

[0031] A method for measuring the load quality of lifting machinery, which can be figure 1 Implemented on the measurement circuit shown. The measurement circuit is composed of microprocessor, current sampling module, voltage sampling module, alarm module, input module and electrical control box connection. The input module is connected with the I / O interface of the microprocessor for parameter setting, correction and calibration, etc. Operation; one end of the voltage sampling module is connected to the three-phase power supply for measuring three-phase voltage, the other end is connected to the I / O interface of the microprocessor, the current sampling module is connected to the motor, and the other end is connected to the I / O interface of the microprocessor / O interface is connected, the three-phase current and three-phase voltage signals coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com