Rotary and stepping torsional-vibration composite-motion mechanism

A compound motion and torsional vibration technology, applied in mechanical equipment, transmissions, belts/chains/gears, etc., can solve the limitation of speed ratio between low-speed rotation and high-frequency torsional vibration, complex structure, and wear of shift fork pins and shift fork grooves Large and other problems, to achieve the effect of good assembly and manufacturing process, simple transmission relationship, and compact mechanism structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now in conjunction with accompanying drawing, the present invention will be further described:

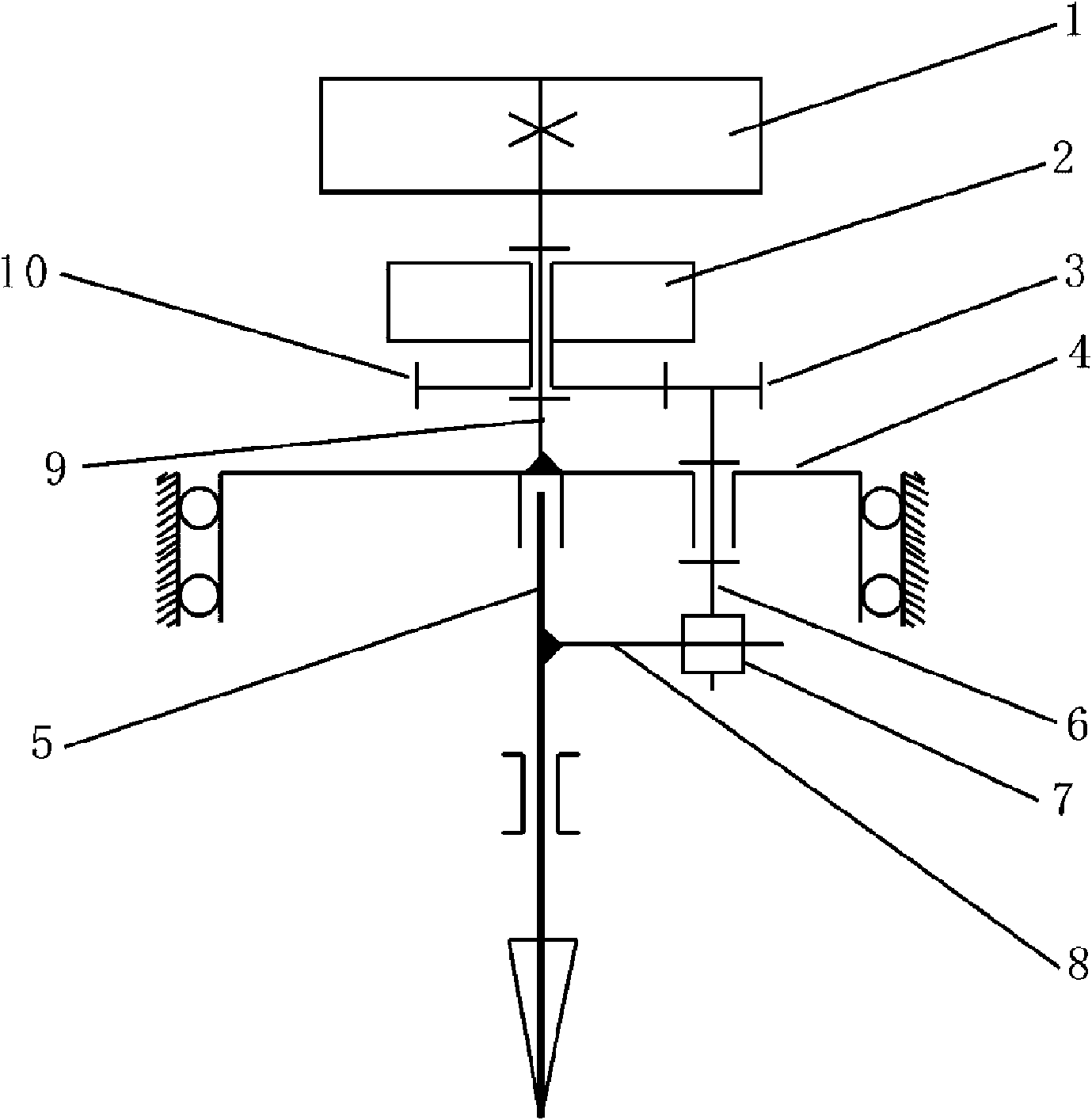

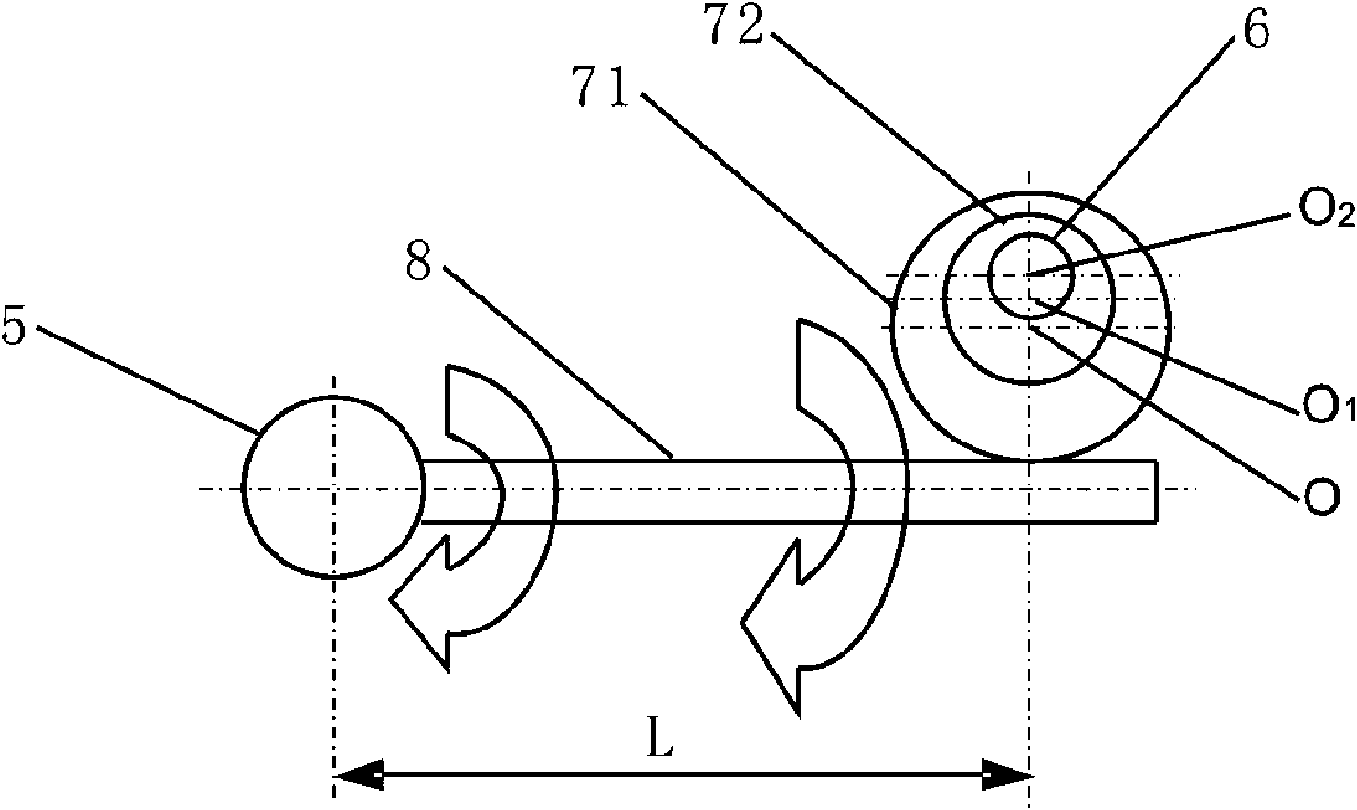

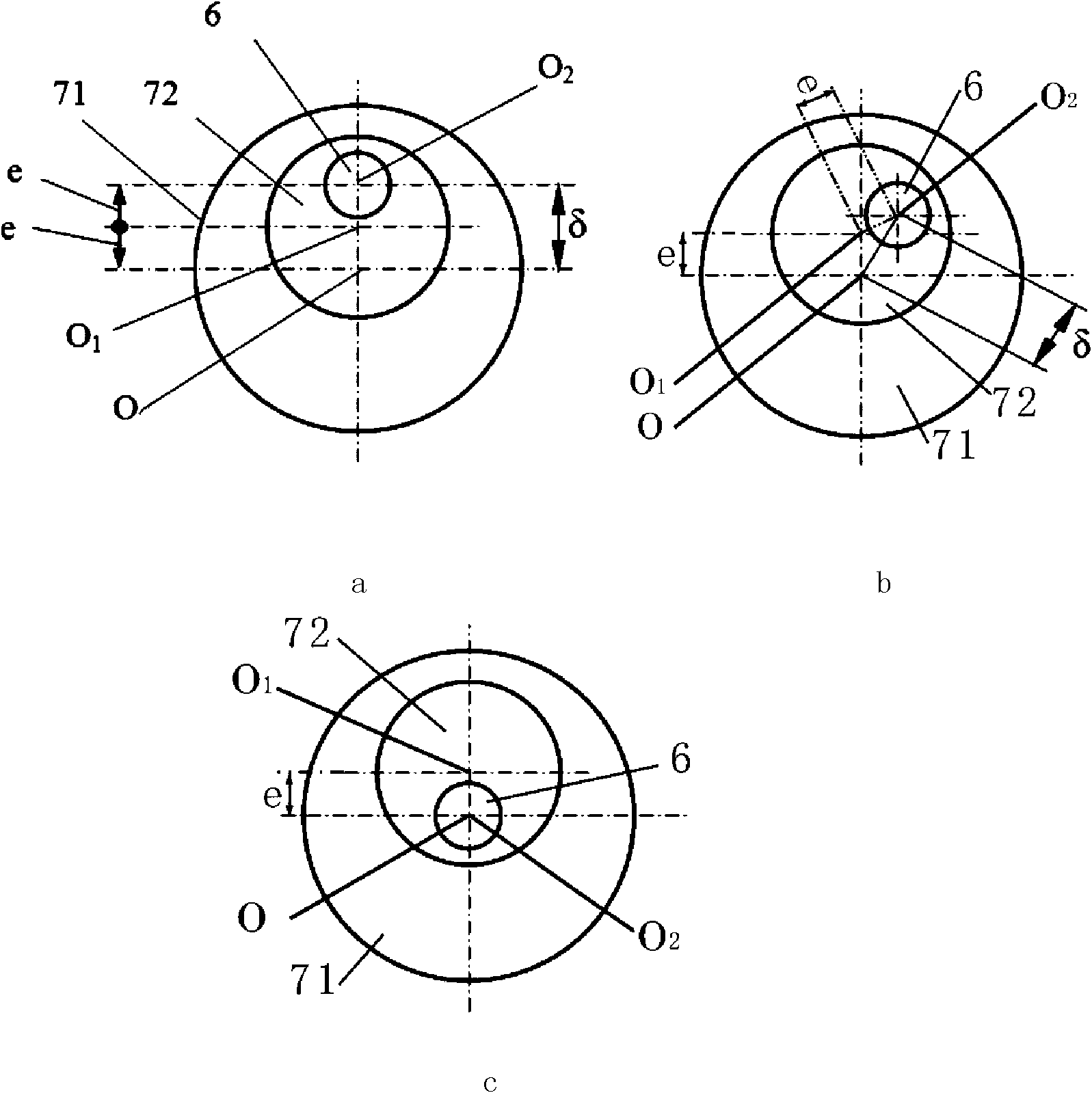

[0028] Such as figure 1 Shown: the present invention provides a kind of rotary and step type torsional vibration compound motion mechanism, comprises shaft A9, rotating cylinder 4, main shaft 5, and the pendulum 8 that is vertically fixedly connected with main shaft 5, and passes through rotating cylinder 4 and is connected with The central axis of the drum 4 is an axis B6 arranged in parallel. The shaft A9 and the main shaft 5 are respectively located on the upper and lower sides of the drum 4 and at the same time on the central axis of the drum 4; one end of the shaft A9 is fixedly connected to the first pulley 1, and the other end is fixedly connected to the drum 4; the first pulley 1 There is also a second pulley 2 and a gear A10 on the shaft A9 between the drum 4, and the second pulley 2 and the gear A10 are coaxially fixedly connected; the gear A10 is externally meshe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com