A multi-stage chain drive wheel vehicle steering mechanism

A technology of steering mechanism and multi-stage chain, applied in steering mechanism, fluid steering mechanism, vehicle components, etc., can solve the problems of unclear structural relationship, low efficiency and high cost, achieve simple and clear transmission relationship, optimize motion relationship, steering flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

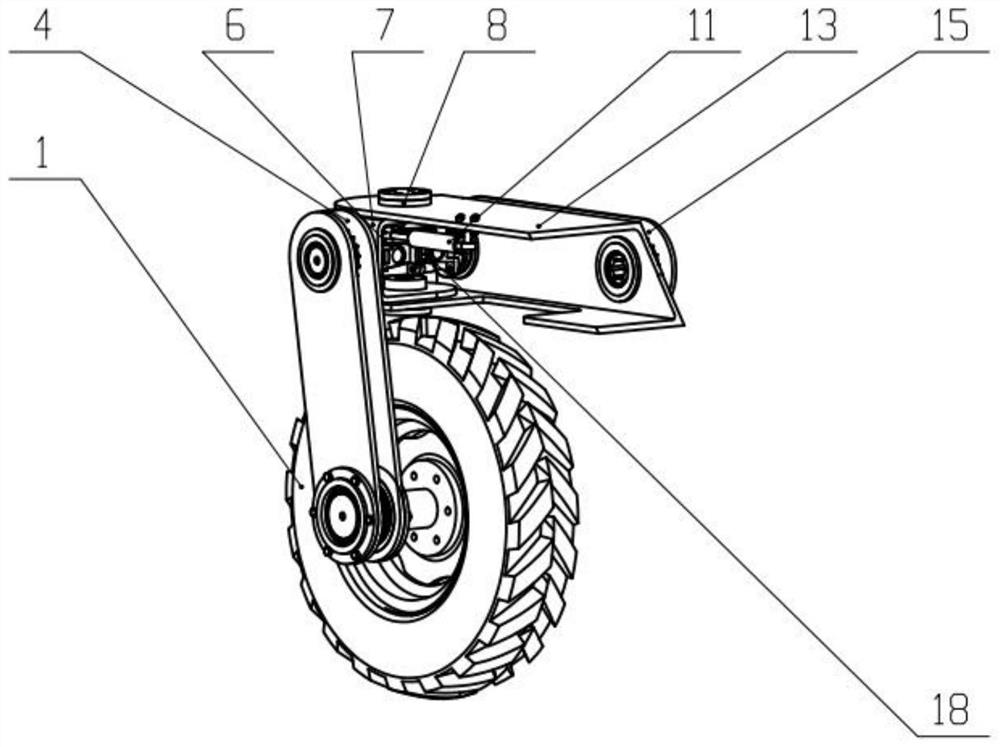

[0024] like figure 1 As shown, the present invention proposes a multi-stage chain drive wheeled vehicle steering mechanism. The steering mechanism consists of a first-level transmission chain fixing plate 15, a cross shaft universal joint one 18, a cross shaft universal joint two 6, a fixed bracket 7, Hydraulic cylinder 11, wheel upper bearing fixing flange 8, front wheel cover plate 13 of frame, second-stage inner drive chain fixing plate 4, right front wheel 1;

[0025] The front wheel cover plate 13 of the frame is fixedly connected with the first-stage transmission chain fixing plate 15, the front wheel covering plate 13 of the frame is fixedly connected with the bearing fixing flange 8 at the upper end of the wheel, and the fixing bracket 7 is also connected with the second-stage inner drive chain fixing plate 4. Fixed connection; the fixed bracket 7 is connected with the bearing fixing flange 8 at the upper end of the wheel; through the bearing connection, the fixing bra...

Embodiment 2

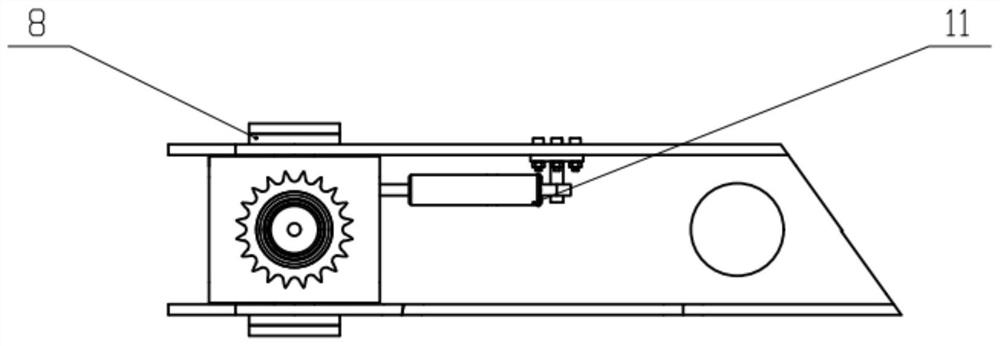

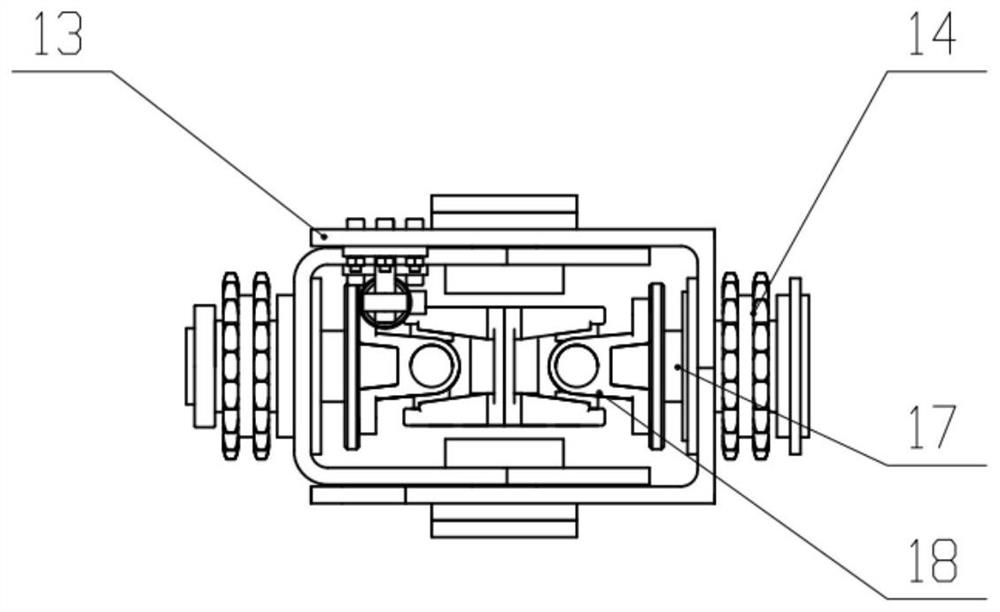

[0028] like Figure 2-5 As shown, the multi-stage chain drive wheeled vehicle steering mechanism includes a first-stage transmission chain fixing plate 15, a cross shaft universal joint 1 18, a cross shaft universal joint 2 6, a fixed bracket 7, a hydraulic cylinder 11, and a wheel upper end bearing The fixing flange 8, the front wheel cover plate 13 of the frame, the second-level inner drive chain fixing plate 4; The bearing fixing flange 8 at the upper end of the wheel is fixedly connected; the first-stage transmission chain fixing plate 15 is fixedly connected with the cross shaft universal joint one 18, and the cross shaft universal joint two 6 is fixedly connected with the second-stage inner transmission chain fixing plate 4.

[0029] like image 3 As shown, the cross shaft universal joint one 18 is fixedly connected with the cross shaft universal joint two 6, and the cross shaft universal joint one 18 can rotate around the cross shaft of the cross shaft universal joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com