Mobile crane having counterweight

一种移动式起重机、配重的技术,应用在起重机等方向,能够解决流体压力缸160、260驱动效率差等问题,达到降低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, refer to Figure 1 to Figure 6 , the mobile crane according to the embodiment of the present invention will be described.

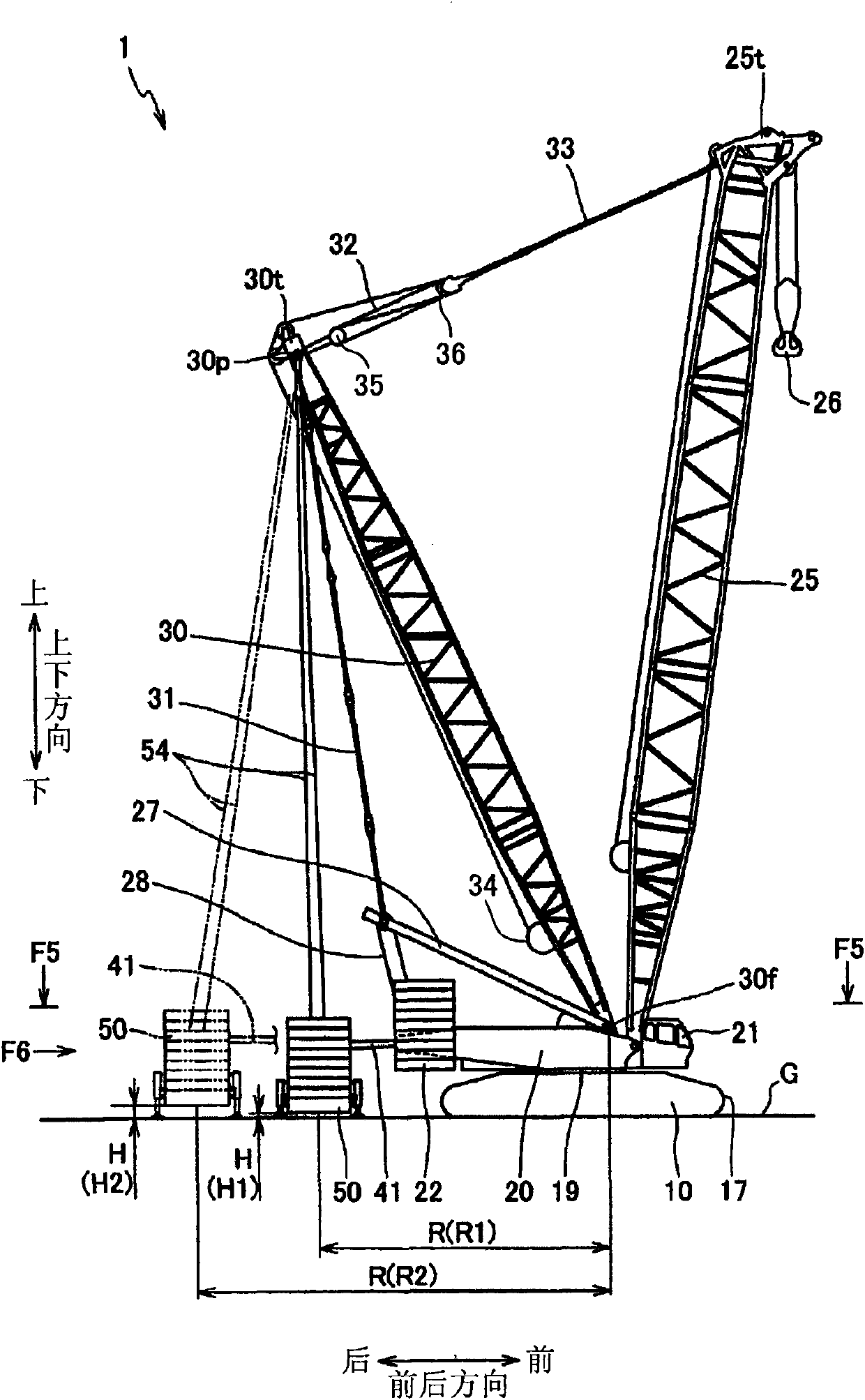

[0030] figure 1 Denotes mobile crane 1 . This mobile crane 1 is a counterweight-balanced crane. That is, this mobile crane 1 is a crane that has a counterweight 50 (additional counterweight) behind the upper slewing body 20 in addition to the upper slewing body rear end side counterweight 22 . Specifically, the mobile crane 1 has: a lower traveling body 10; an upper revolving body 20 rotatably mounted on the lower traveling body 10; 30, mounted on the upper slewing body 20 in a fluctuating manner behind the boom 25; The upper end of the mast 30 hangs. Additionally, if Figure 4A As shown, a plurality of hydraulic cylinders 60 are mounted on the counterweight 50 as counterweight lifting cylinders.

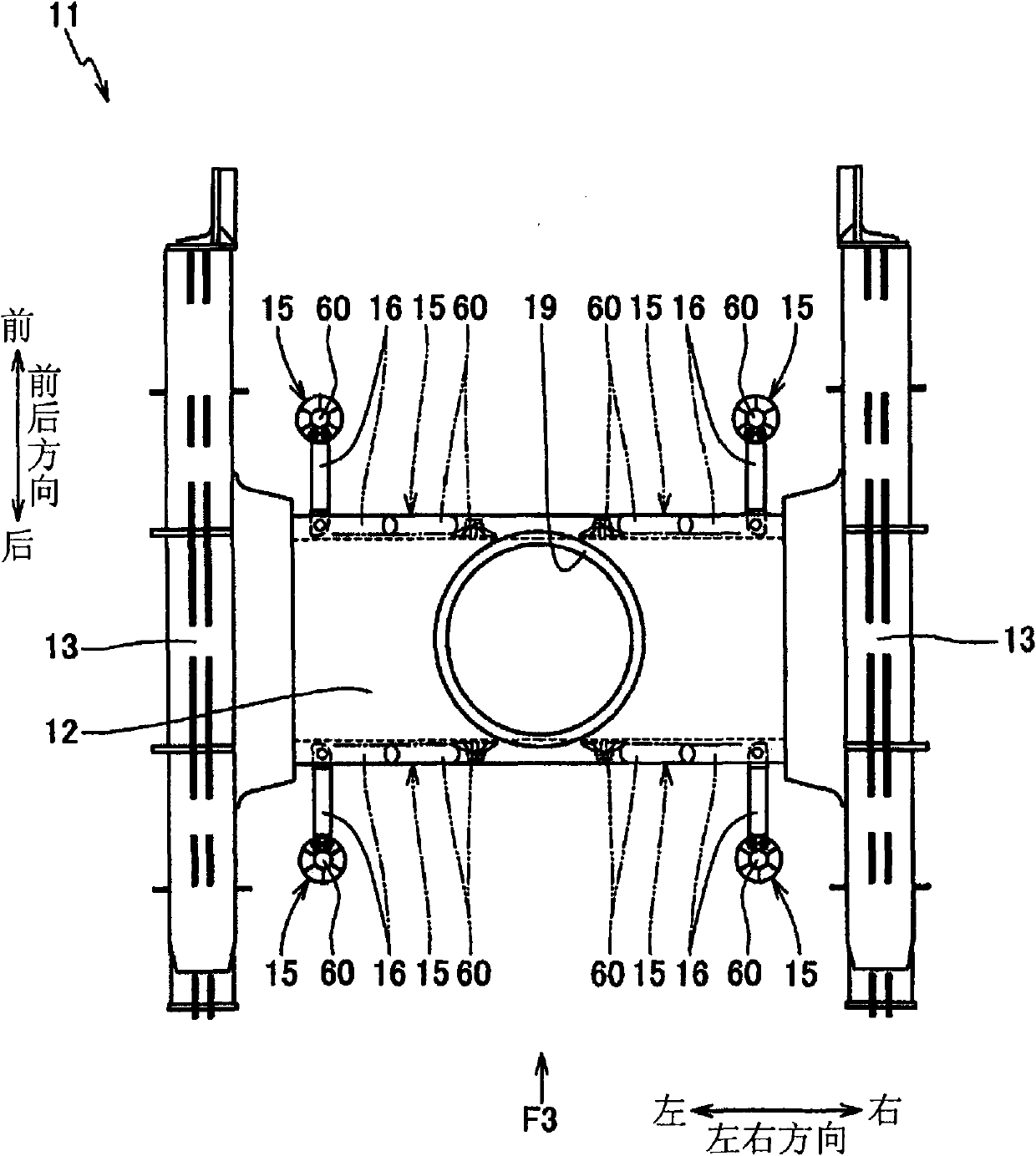

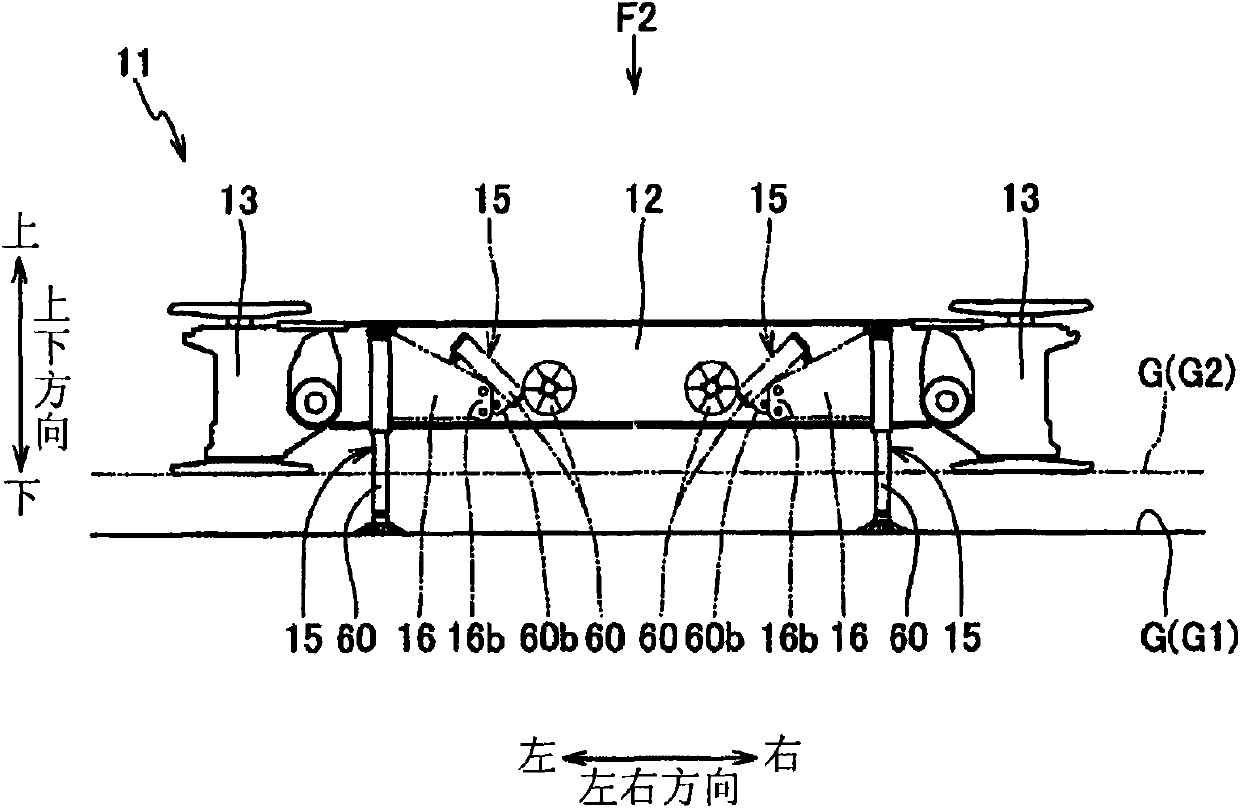

[0031] The lower walking body 10 has figure 2 The walking body main body 11 shown and a pair of caterpillar belts 17 ( figure 1 ), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com