Waste filling supporting bracket

A technology of gangue and gangue beams, which is applied in the field of supporting equipment for comprehensive mechanized coal mining working faces in coal mines, can solve problems such as structural instability, roof collapse, production safety accidents, etc., to control deformation, expand coverage, and improve overall The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below through embodiments in conjunction with the accompanying drawings.

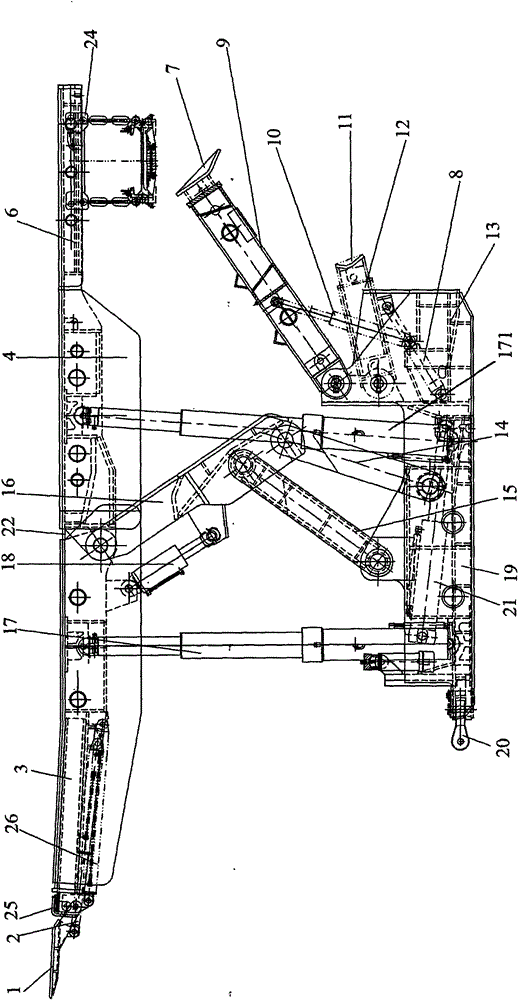

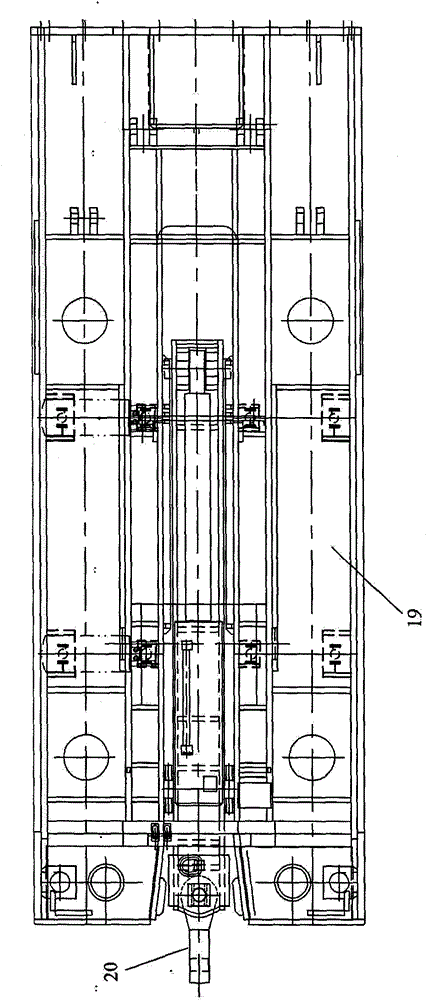

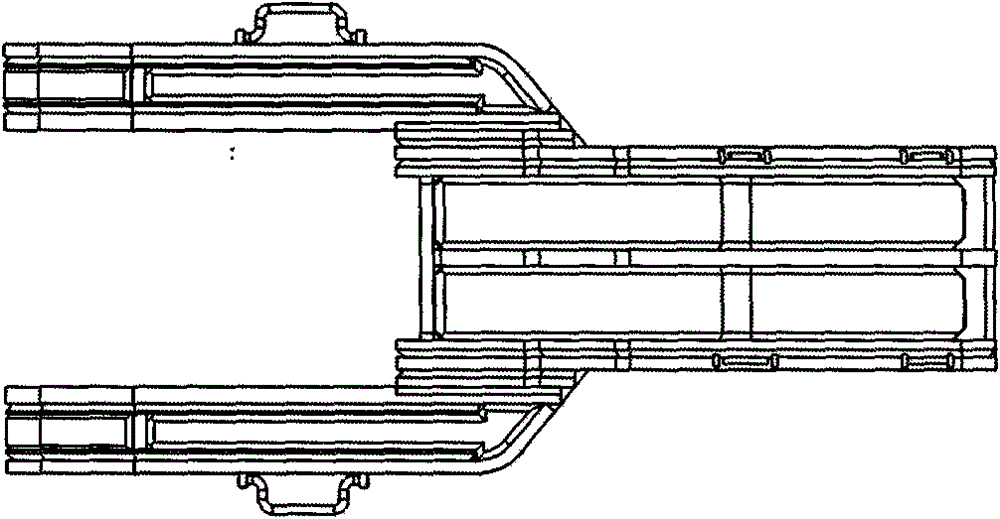

[0016] Such as figure 1 , figure 2 and image 3 As shown, in the present embodiment, including the protection side 1, the top beam 3, the column 17, the four-bar mechanism, the base 19, the scraper conveyor and the compacting mechanism, a telescopic beam 25 is built in the front end of the top beam 3 along the front and rear direction, A telescopic beam jack 26 is hinged between the telescopic beam 25 and the top beam 3, and the guard 1 is hinged at the front end of the telescopic beam 25. By arranging the telescopic beam, the supporting range of the support can be enlarged. Side protection jack 2, front link 15 and rear link 14 are hinged on base 19, the upper end of upper link 16 is hinged on top beam 3, upper link 16, front link 15, rear link 14 and base 19 Mutually hinged to form a four-bar linkage mechanism, wherein the hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com