Semi-active vibration absorber

A semi-active shock absorber and shock absorber technology, which is applied to shock absorbers, liquid shock absorbers, shock absorbers, etc., can solve the problems of high processing cost and the influence of dynamic response of damping force, and achieve low cost, adjustable Fast, improved lateral stability and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

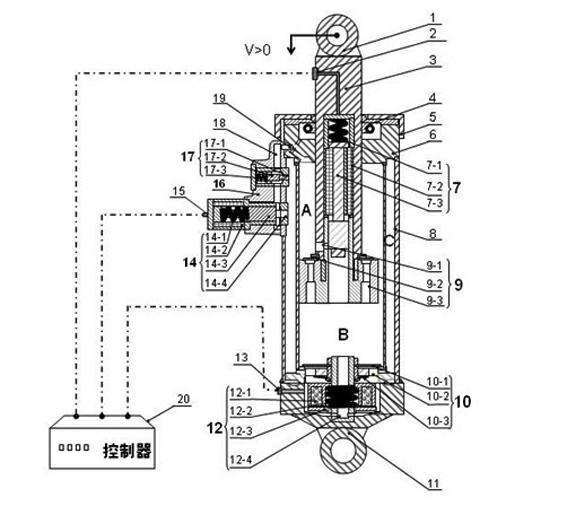

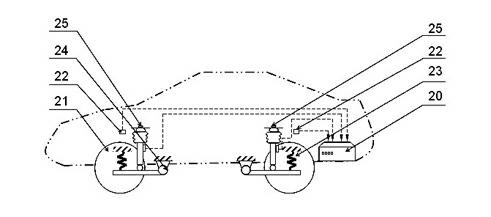

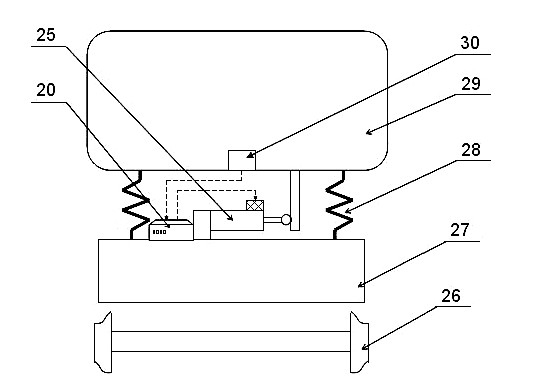

[0015] attached by figure 1 As shown: the shock absorber includes end connecting rings 1 and 11, piston rod 3, seal 4 and guide device 6, cylinder body 8, shock absorber cover 5 threadedly connected with the cylinder body, piston valve assembly 9, bottom The valve assembly 10 is characterized in that it also includes a tension unloading solenoid valve assembly 7 built in the piston valve assembly 9 and the piston rod 3, a compression unloading solenoid valve assembly built in the bottom of the bottom valve assembly 10 12 and an external high-pressure small oil chamber 18 which is arranged in the boss 16 and has a main control valve assembly 14 and a safety valve assembly 17. The tension unloading solenoid valve assembly 7 , the compression unloading solenoid valve assembly 12 and the main control valve assembly 14 are controlled by a controller 20 .

[0016] The external high-pressure small oil chamber 18 is formed by the partial connection between the boss 16 on which the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com